Cette page fournit une simple interface de navigation pour trouver des entités décrites par une propriété et une valeur nommée. D’autres interfaces de recherche disponibles comprennent la page recherche de propriété, et le constructeur de requêtes ask.

Liste de résultats

- Ecoline - Datum and MitreOffset Tests + (When an Ecoline is commissioned, the posit … When an Ecoline is commissioned, the positional accuracy needs to be set up.

These are also useful tests to check if the machine is maintaining positional accuracy

tent, repeatable results before making any parameter changes</div> </div><br/>) - PLC Source Control - Git Credential Manager for Windows Install + (When connecting to the tc3Multi repository … When connecting to the tc3Multi repository on BitBucket.org, some times the validation credentials are not accepted. Check that the password you have is correct, if the problem persists , install or update Git Credential manager for windows to the latest version.manager for windows to the latest version.)

- R0000299 Stroke assembly rebuild + ( The following instructions should be fol … The following instructions should be followed to ensure that correct assembly and setting are performed '''Tools / consumables Required''' Standard hex key set Standard spanner set Large adjustable spanner Drifts and punches Ballpein hammer Soft hammer FE10 Solvent Hylomar Gasket '''Parts Required''' Kit R0000299 containing B0000043 Double Angular bearing 15 I?D 35 O?D 15.9 long rubber seal 3 x 2 B0000105 Double Angular Bearing 15 I/D 35 O/D 15.9 Long x 1 B0000335 3ph Brake motor 2 pole 3000rpm x 1 B0000380 Double Angular Bearing 25 I/D 52 O/D 20.6 Long + rubber seal x 2 D0000059 Damper Bridge x 1 D0000062 Damper Bridge Boss x 2 D0007730 ZX4 V Notch Mk1 Spindle Shaft x1 D0007867 Bevel Gear (Left) x 1 D0007868 Bevel Gear (Right ) x 1 D0007873 Motor Gear x 1 D0007874 Pinion Gear x 1 D0007875 Pinion Shaft x 1 P0000165 damper x 174 Pinion Gear x 1 D0007875 Pinion Shaft x 1 P0000165 damper x 1)

- Importing Picking List from Sage To Monday + (This procedure demonstrates how to use the … This procedure demonstrates how to use the "Sage Hooks" MS Access database to grab the data created in Sage and exort to a spreadsheet. The spreadsheet is then imported into a new Monday board, then copied across to the correct Picking List for the machine build.

Picking List for the machine build. <br/>)

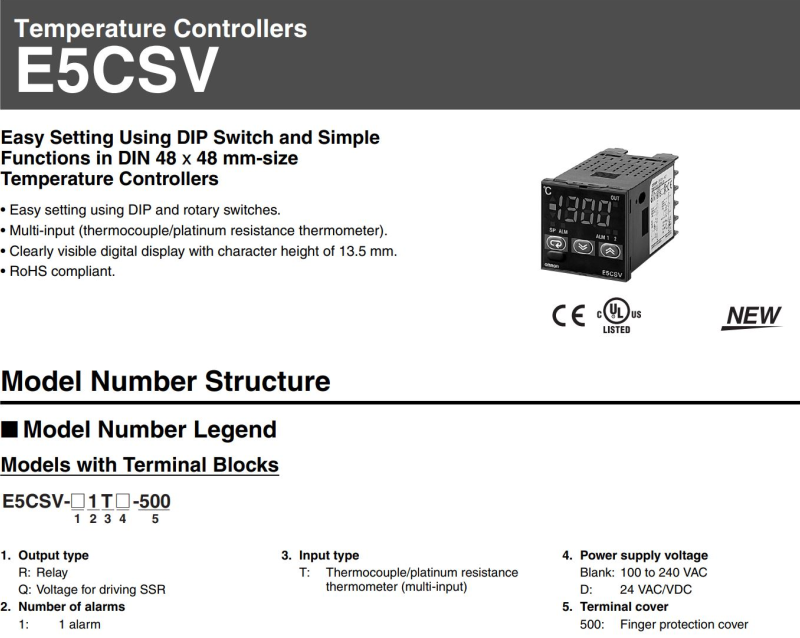

- Omron E5CVS PV Shift + (<div class="annotatedImageDiv" typeof=" …

) - Upgrading Autoflow TwinCAT2 to Win10 and TwinCAT3 + (<div class="annotatedImageDiv" typeof=" … Autoflows from A2001 to A2015 were initially produced with TwinCAT2 software. This has now been superseded with TwinCAT3 which then has the benefit of compatibility with version 6 front end software.

The original PC cannot be used because

*It is not powerful enough to run v6 front end

*The operating system cannot be upgraded to Windows 10

*It cannot be upgraded to TwinCAT3

The Beckhoff C6015 PC has been chosen to be the replacement PC. It is compact, yet powerful enough to run the v6 front end and TwinCAT in the same

. It has an upgrade to 1.9Ghz 4 core processor.

Because it has a limited 40Gb SSD memory, a compact 64Gb memory stick is inserted into the USB 3.0 port. This acts as a separate drive for the DDRIVE dynamic storage for all machine setup. The internat drive is for the Operating System only. This mimics the current Autoflow setup of a remote Camera PC, hence the camera PC can be retired after the upgrade

era PC, hence the camera PC can be retired after the upgrade<br/>) - Autoflow Maintenance - Gripper + (<nowiki>The following preventative m …

The following preventative maintenance tasks should be carried out regularly on the machine. The frequency depends on the machine use, but as a guide: i-Weekly<br />20 Hrs/Week Monthly</pre></div></nowiki>)2-3 Shifts Weekly

40 Hrs/Week Bi-Weekly

20 Hrs/Week Monthly - Autoflow Maintenance - Infeed + (<nowiki>The following preventative m …

The following preventative maintenance tasks should be carried out regularly on the machine. The frequency depends on the machine use, but as a guide: kly<br />20 Hrs/Week Monthly</pre></div><br/></nowiki>)2-3 Shifts Weekly

40 Hrs/Week Bi-Weekly

20 Hrs/Week Monthly - R0000712E Rotary Trunking + ('''<u>Tools Required</u>''' … '''Tools Required''' Standard set Hex keys Standard socket set Countersink bit and drill Copper/hide hammer Standard hss drill set '''Parts Required''' D0006210 pre assembled energy chain D0003929 Access panel D0003930 Circular guide D0003985 Upper circular guard D0007817 Circular guard D0001171 plug bracket P0001023 6mm y adapter x 9 P0000401 non return valveug bracket P0001023 6mm y adapter x 9 P0000401 non return valve)

- R0015060 Bench Assemble Flapper Beam + ('''<u>Tools Required</u>'''

… '''Tools Required'''

Standard hex key set

Tape measure

Steel rule

Engineers square

'''Parts Required'''

B0001099 Bush flange 10 i/d 12 o/d x 14

C0001018 EP2338-0001 EtherCAT Box 8 Configurable IO x 1

D0010167 Ethercat Mount Plate x 1

D0015353 Sensor Flapper Pivot x 8

D0015355 Sensor Flapper Plate (312) x 6

D0015357 Sensor Flapper Plate (270) x 1

D0015363 Sensor Flapper Support Transfer x 1

E0000336L Sensor: M8; 4mm, PNP N/O, M8 conn x 7

F0000537 dowel pin 10 x 40 x 8

M0001016 Angle 74 x 38 x 2

M0001209 Bracket m8 proximity sensor bracket 90 deg x 7

'''Fastener list'''

M5 x 6 Grubscrew kcp 8 off

10mm x 40 dowel 8 off

M6 x 20 socket cap 8 off

M5 D nut 14 off

M6 D nut 10 off

M8 D nuts 8 off

M5 A form washer 7 off

M5 x 10 socket cap 7 off

M5 x 10 button socket 7 off

M3 x 20 panhead 2 off

M6 x 16 socket cap 2 off

M6 A form washer 2 off

M8 x 20 socket cap 8 off

M8 heavy motor plate washer 8 off

Cable tie bases 7 off

t cap 8 off M8 heavy motor plate washer 8 off Cable tie bases 7 off <br/>) - R0015095 Bench Assemble Infeed Support Arms + ('''<u>Tools Required</u>''' … '''Tools Required''' Standard hex key set Standard tap sete Setting jigs '''Parts required''' B0001170 Spacer 180 off B0001155 open rail 18 off D0015553 Transfer Support arm R/H (right to left machine ) OR D0015552 Transfer Support Arm L/H ( Left to Right machine) D0015554 x 18 M8 x 20 button hex fastener x 18 M5 x 25 socket cap x 180 M5 A form washer x 180ex fastener x 18 M5 x 25 socket cap x 180 M5 A form washer x 180)

- R0015250 Bench Assemble Support Arms + ('''<u>Tools Required</u>''' S … '''Tools Required''' Standard hex key set Standard tap sete Setting jigs '''Parts required''' B0001170 Spacer 180 off B0001155 open rail 18 off D0015552 Transfer Support arm R/H (right to left machine ) OR D0015553 Transfer Support Arm L/H ( Left to Right machine) D0015554 x 18 Transfer Support Arm L/H ( Left to Right machine) D0015554 x 18)

- R0015337 Bench Assemble Guarding Components + ('''<u>Tools Required</u>'''

… '''Tools Required'''

Standard hex key set

Standard spanner set

Standard HSS drill set

Acoustic mat cutting board and straight edge

Utility blade

'''Parts Required'''

D0000770 Door Hinge (M0016) x 2

D0001886 Front Door Saw Mk 4 x 1

M0000002 12mm Grey Acoustic Foam with Black PVC Facing x 1

M0000539 Handle Black Nylon 200mm M8 Fixings x 1

M0000031 panel edging ( consumable stock )

M0000150 Stuga sticker clear x 1

M0000154 Stuga service sticker x 1

uga sticker clear x 1 M0000154 Stuga service sticker x 1 <br/>) - R0015041 Bench Assemble Top Hood Assembly + ('''<u>Tools Required</u>'''

… '''Tools Required'''

Standard hex key set

Standard spanner set

Standard Hss drill set

Standard tap set

Acoustic foam cutting board and straight edge

Utility Blade

'''Parts Required'''

Pre wired light, beacon and network cable from electrical department

C0001152 Camera: HikVision DS-2CD2343G0-I-2.8mm x 1

C0001239 Micro SD Card 32Gb Class 10 x 1

D0000770 Door Hinge (M0016) x 2

D0001877 Saw Top Door Mk4 x 1

D0004641 Hinge Pin Block (D7445) x 1

D0004642 Flap Counterbalance Bar x 1

D0004645 Safety Flap Hinge Pin x 1

D0004679 Flap Stiffening Bar x 1

D0004705 Flap Hinge Bar x 1

D0004747B top door screen x 1

D0004807 Flap x 1

D0007445 Hinge Pin Block OH (D4641) x 1

D0016251 Saw Hood Switch Mount Plate (Bernstein) x 1

E0000275 Button: Base Fixing 1 N/C x 1

E0001072 Emergency Stop Module Bevelled 1NO 1NC x 1

E0001569 Guard Lock Switch: Bernstein Radius Actuator (Key) x 1

H0004643 4mm Axxis Clear 145mm x 690mm x 1

M0000002 12mm Grey Acoustic Foam with Black PVC Facing x 1 (consumable stock )

M0000036 Sign - Ear Protection x 1

M0000048 Gas Spring 15mm x 100mm x 1

M0000539 Handle Black Nylon 200mm M8 Fixings x 1

100mm x 1 M0000539 Handle Black Nylon 200mm M8 Fixings x 1 <br/>) - Stuertz Infeed - Freeing Roller under Gripper Arm + ('''Applies to: A2026-A2030 Autoflow Mk4 wi … '''Applies to: A2026-A2030 Autoflow Mk4 with Jetta Locking motors'''

In certain circumstances, the forward clamp roller arm has stuck itself under the gripper arm. Freeing from this situation requires a set process because the GZ axis motor is braked and probably in an overload condition

nfident in using TwinCAT on the VM machine to navigate to settings</div> </div><br/>) - OBSOLETE Installing SourceTree Version Control Software + (<div class="icon-instructions caution-i … Use this [https://stuga.dokit.app/wiki/Changing_Version_Control_to_Visual_Studio link] From Jan 2020, Sourcetree will be increasingly used to properly maintain changes to the Stuga source code. Each machine with TwinCAT3 will need the Sourcetree program installed, and a change to where and how the source code is stored This tutorial deals with installing the Sourcetree program from Atlassian code is stored This tutorial deals with installing the Sourcetree program from Atlassian)

- DM - Updating Resources + (<div class="icon-instructions caution-i …

All information provided to the service engineers on Device Magic can all be linked to a single Excel document. This document provides all customer names, machine numbers, emails and employee information. Linking this document with Device Magic provides fields that make it easier for engineers to fill out the form.

used internally at Stuga and not be sent to engineers or customers in coordination with Data Protection standards.</div> </div><br/>) - R0015338 Bench Assemble Serial Plate + (<u>'''Tools Required'''</u> Serial plate stamping jig Large Alphabetic and Numerical stamps Correct machine build data <u>'''Parts Required'''</u> D0000086B Universal Serial Number Plate (UKCA) x 1 <br/>)

- R0015290 Bench Assemble Top guard + (<u>'''Tools Required'''</u>

… '''Tools Required'''

Standard hex key set

Acoustic foam cutting edge and Back board

Stanley blade

Standard HSS drill set

Standard tap set

Step drill

'''Parts Required'''

D0001352 Printer Shelf TLP2844-Z x 1

D0004719E Cut Bar Guard Mk5 (5476E) x 1

E0000249 Sounder Beacon x 1

M0000002 12mm Grey Acoustic Foam with Black PVC Facing x 1

M0001127 Cable Tie Base (m6) x 1

with Black PVC Facing x 1 M0001127 Cable Tie Base (m6) x 1 <br/>) - TB0444 Renewing CF Card on TwinCAT2 Systems + (<u>Problem</u> These machines … Problem These machines use a CX5020 PC with a 2Gb CF card running TwinCAT2 PLC system. The CF card can fail, which is effectively the windows operating system. The CF card has a very small capacity, so needs to be created from an image. This TB outlines the steps in the process to ensure a successful conclusion. 1. Create a new CF card at stuga using the beckhoff imaging tool on a CX5020 2. Boot up with the CX5020 3. Ensure PLC is set to Enable on start-up (default is config mode) 4. Rename the PC 5. Install TeamViewer host v10 or less from a USB stick 6. If you have a copy of the version of winMulti it was running, copy this in to the c:\ multi folder. If not, a “'''''new version install'''''” will be needed so copy in data from the g:\builds\PC Installs\Autoflow\Multi folder 7. Set up and customer specific network parameters to ensure TeamViewer will work when it is plugged in on site 8. Send to customer Once on site, follow procedure A if the winMulti version is preserved, or B if it is a '''''new version install'''''eserved, or B if it is a '''''new version install''''')

- TB0415 Method to Prevent Loosening of Saw Blade + (==Problem==

On Z063 the bolt holding the s … ==Problem==

On Z063 the bolt holding the saw blade onto the spindle has regularly been loosening during use.

==Solution==

The M16 bolt will be replaced with a stud and castle nut that can be locked with a cotter pin.

==Tool List==

Drill with Ø5.0 bit

24mm Spanner

C Spanner

= Parts List =

0000549 </td><td width="319">Split Pin 4mm x 32 </td><td width="302">1 </td></tr><tr valign="TOP"> <td width="76">F0000550 </td><td width="319">Castle Nut M16x1.5 </td><td width="302">1 </td></tr></table>)D0004031B Saw Washer 3mm 1 D0015560 Spindle Stud 1 F0000273 Spirol Pin Ø6 x 30 1 F0000549 Split Pin 4mm x 32 1 F0000550 Castle Nut M16x1.5 1 - Monday - Getting Started For Engineers + (==Why Change?==

*mHelpdesk limitations

** … ==Why Change?==

*mHelpdesk limitations

**Cludgy to use

**Slow response

**Cannot connect to other apps or emails

*Monday advantages

**Easier and more elegant to use

**More configurable

**easy to email into

**Better searching

**Expandable to whole business

**Cheaper

==Similarities to mHELPDESK==

*Monday consists of a set of user definable “Boards” that contain a list of “Pulses”.

*The “pulses” can be configured however we like.

*I have created a “Board” called “Service Jobs”

*On the Service Jobs Board, I have designed the “Pulses” to mimic the service jobs, so this will include the machine, the status, the type classification, etc

*Any pulse has associated “Updates”. These are just like the “items” on an mHelpDesk job, but is much more flexible than the plain text of mHelpdesk

*The service team will assign jobs as before

*The job should be updated by yourself during your visit

*The database of jobs is searchable so you can find the machine history

so you can find the machine history <br/>) - TB0436 Creating a Backup Through WinMulti + (A backup zip folder of all necessary files can be created in WinMulti. By pressing the backup button (F11) and navigating to the backup’s folder (C:\multi\backup) a machine backup will be created.)

- Changing the Flowline Ops Password + (A password can be set up within FlowlineOps that limits access to the Edit Machining and Edit Profiles buttons, This tutorial will explain how to setup or change this password.)

- Saje uPVC Unloading Process + (Access for machinery is limited at the Saj … Access for machinery is limited at the Saje factory.

The machine will be delivered in the following modules, that should be unloaded from the lorry in this order

#Electrical Cabinet

#Machining centre base module (1.8 x 2.2m)

#Infeed module (2.4 x 9.0m)

x 2.2m) #Infeed module (2.4 x 9.0m) <br/>) - Correcting Linearity with Rack Offset File + (Accuracy problem on A2001 was traced to a … Accuracy problem on A2001 was traced to a non-linear rack. This tutorial demonstrates how to test the linearity of a rack and the systems in place to correct the linearity. machine in the 20 year history that has needed these alterations</div> </div>)

- ZX5 - ZX3 Hepco alignment Module E Saw Infeed + (Alignment and check procedure for mounting … Alignment and check procedure for mounting of hepco rail To main frame Parts required B0001102 hepco rail D0015492 5 off vertical adjustment plate D0015493 5 off Lateral adjustment plate D0015072 1 off Carriage Plate B0000184 journal wiper 4 off B0000185 journal 2 off B0000186 journal 2off Hepco Levelling Jig Hepco rail v block jigs Hepco rail Drive rack pitching jigk jigs Hepco rail Drive rack pitching jig)

- ZX5 Production R0015040 Module F to R0015001B Module E alignment + (Alignment criteria and steps for correct machine installation)

- ZX5 Production R0015139 Module B to R0015000B Module C alignment + (Alignment details and level settings for correct alignment of module B to module C)

- Monday - Obtaining Customer or Machine Address from a Job + (All machines in the Monday database have their locations stored to make it easy for an engineer to navigate to site using the map features in Android or Apple phones However, it is not intuitively clear how to get to this information)

- VM Upgrade Software + (As an alternative to having a separate camera PC. Adding a VM (Virtual Machine) to the Front end allows access to the BE and cameras without interrupting the operator.)

- R0000728 R0000729 Stroke Assembly Dismantling + (Assemblies fitted to MK1 ZX4 will require … Assemblies fitted to MK1 ZX4 will require refurbishment at some point of life cycle.

The following instructions should be followed to ensure that correct assembly and setting are performed

'''Tools Required'''

Standard hex key set

Standard spanner set

Double pin saw flange spanner

Drifts and punches

Ballpein hammer

Soft hammer

Degreasing bath

pein hammer Soft hammer Degreasing bath <br/>) - Autocut Taking A Backup + (Backing up is vital to ensure your data is safe in case there is a failure of the PC or Hard Disk Drive)

- Saw machining centre alignment and level check points + (Bullet pointed checks to determine correct alignment of key components within Sawing unit)

- R0000164 Spindle Build + (Clear build instructions for the assembly of R0000164 spindle assembly)

- R0000711 Rotary Base Assembly REV2 + (Detailed steps to correctly install rotary … Detailed steps to correctly install rotary gear and journals Checks for correct installation of oil feed system Tolerance limits and requirements '''Tools Required''' Standard hex key set 0-25mm micrometer Ring support blocks for assembly Work Table Mag Base and D.T.I Hepco flat spanner 17mm socket Torque Wrench '''Parts required''' D0006423-2mod Drive ring x 1 D0007651 Face plate x 1 B0000185 journal x 6 B0000186journal x 2 D0006503 Journal washer x 8 D00007692 wiper x 4 D0006521 x2 D0007693 x 2 D0007713 rotary ring cap x 1iper x 4 D0006521 x2 D0007693 x 2 D0007713 rotary ring cap x 1)

- ZX5 Production R0015122 Module A to R0015139 Module B alignment + (Details and steps for correct alignment of Module A to Module B '''<u>Tools Required</u>''' Laser Level 300mm rule 1 meter yellow level 24mm spanner Permanent marker Pipe cutters Ring main connection equipment)

- ZX5 Production R0000548E Module G to R0015040 Module F alignment + (Details for correct alignment of module G to module H To include fitting of front safety tray once module G is installed)

- R0000204 Notching gear boxes assembly + (For longevity and correct running , it is … For longevity and correct running , it is imperative these units are assembled to the correct tolerances and assembled in the way detailed by this procedure

Tools required

Standard Hex Key Set

Castle nut spanner

Loctite 243 thread lock

Loctite 641 bearing fit

Mandrel jig

Grease applicator

Fe10 solvent spray

ease applicator Fe10 solvent spray <br/>) - Placing a TwinCAT3 Machine Under Source Control + (<div class="icon-instructions caution-i … Click [https://stuga.dokit.app/wiki/Changing_Version_Control_to_Visual_Studio here] for the latest procedure For many years, the source code for the PLCs has resided on the G:\drive and then a copy on each and every one of the PCs used to edit the code, so at least one on each machine. This is a recipe for disaster because maintaining all the copies and version numbers is incredibly difficult and adds a lot of time overhead to fixes and changes. This has worked because there has been only one developer, but this is set to change in future as more programmers will be trained and tracking versions becomes more difficult From 2020, the PLC code version control has been improved by using an industry standard source control system called "Git" along with "BitBucket" to store the PLC code in the cloud. The program "SourceTree" is used to commit, push and pull the changes [https://www.atlassian.com/git/tutorials/what-is-version-control Click here] for an introduction to version control using Git This tutorial is a step by step guide to setting up an existing machine or diagnostic PC to a standard uses on all Stuga machines to enable quick, easy and stress free version control.standard uses on all Stuga machines to enable quick, easy and stress free version control.)

- Installation Procedure - Autoflow Mk4 + (General Procedure is * Prepare Area * Unload from Transport * Locate and level infeed table * Locate, level and align machining module * Locate, level and align outfeed table * Fix to floor * Locate waste conveyor system * Guard fencing assembly)

- Full Version Upgrade TwinCAT3 WinMulti + (If a PC fails on a machine in the field an … If a PC fails on a machine in the field and the hard drive data cannot be recovered, it is necessary to replace the PC. This may create a version conflict, as the new PC will have later versions of twinCAT installed than the original

This tutorial outlines the steps required to bring all the machine systems up to the latest level to ensure compatibility

ions-text">...This is a one-way process that cannot be reversed</div> </div><br/>) - Hotswap Beckhoff PLC with Licence Slice Installed + (If a machine is set up with an EL6070 Licence Slice, the PLC can be swapped freely and the TwinCAT licence remains on the slice in the machine)

- Disabling a Tool Home or Tool Out Sensor + (If there is a failure of a tool out or too … If there is a failure of a tool out or tool home sensor on the Stuga spindle ring, it is important to be able to quickly disable the input so the machine can continue production until the problem can be properly resolved. The software has an inbuilt functionality to do this - this tutorial takes you through the necessary stepsrial takes you through the necessary steps)

- Create a TwinCAT Project from Existing Project + (If you are confident and proficient in usi … If you are confident and proficient in using the Visual Studio editor to create TwinCAT projects, you can shortcut a lot of the data inputting by copying and modifying an existing project. This will keep the naming conventions and links exactly the same

ne has exactly the same EtherCAT box, drive and module setup</div> </div><br/>) - Changing Version Control to Visual Studio + (In March 2022 the password policy of the s … In March 2022 the password policy of the system behind SourceTree / Bitbucket and Atlassian changed - [https://community.atlassian.com/t5/Bitbucket-articles/Announcement-Bitbucket-Cloud-account-password-usage-for-Git-over/ba-p/1948231 link]. This meant all machine would need a complex password login change for the SourceTree program used for version control of the PLC code. This was not straight-forward to resolve, so the decision was made to change the version control system to the one that is packaged with the Visual Studio system by default. This is a better method anyway, but it needs the "TcXaeShell" installed. Visual Studio that includes Source control, rebadged for TwinCAT3</div> </div>)

- J0001000H Autoflow Mk4 Mechanical installation-Alignment + (Information to clarify correct process for installation of J0001000H Autoflow Mk4 Levelling tolerance of 0.004" /0.1mm over 300mm (1 division on engineers level) must be adhered to)

- TB450 - CMOS Battery replacement + (Internal CMOS batteries are used in PCs to … Internal CMOS batteries are used in PCs to keep a constant power supply to BIOS memory while the main power supply is switched off. These batteries should last up to 5 years when a PC has been left idle. Sometimes these batteries can fall flat before this time either due to being low when sent out or extended use on older machines. The main symptom of a CMOS battery faulting on a Stuga machine is the PC not booting up when mains power is switched on which will be indicated by a “No Signal Detected” message being displayed on the screen. This is due to the BIOS setting “Restore AC Power Loss” going back to its default value of OFF due to the battery faulting. Restoring the BIOS to its original settings is a temporary fix in this situation as it is most likely this will happen again a couple of months down the line (See TB 376 or 213). The battery required is a '''CR2032'''. In the case of the Antec PC, and most commonly, the battery is held in an open housing that can be pushed to release and easily replaced. In PCs such as the Acer Revo the battery needs to be pre-wired with a plug but still easily unclipped and replacedug but still easily unclipped and replaced)

- Monday - Putting Customer Machines On Stop + (It is important that everyone does this th … It is important that everyone does this the same way or confusion and frustration will follow. It is also important to understand how the relationship between a Machine and it’s contract works * Each machine on the “Machine” board needs to link to a “Contract” on the “Service Contracts” board * This allows multiple Machines to have the same “Contract” – eg Customade group contract * The “Contract” is the electronic version or equivalent to the bit of paper that the customer has signed, and contains the start and end dates, etc * For machines that have no contract, I have set up some other “General” contract types. These General Types are not machine specific – ** PAYG – General Pay as you go ** OnStop – Customer is on stop and nothing should be supplied ** AskFirst – Ask KG or management first before supplying goods and services ** Proforma – Payment required before supply of goods and services ** PreDelivery – Before warranty startses ** PreDelivery – Before warranty starts)

- Stuertz Infeed - Check GY Position Parallelism + (It is important that the parallelism of th … It is important that the parallelism of the GY axis to the backfence is set and maintained along the length of the rack. This tutorial describes how to check this parallelism without the need for measuring equipment

Potential Symptoms of a problem

*Gripper cannot pick up offcuts

*Gripper /profile end forced away from backfence

*Accuracy problems

*Gripper wobbles after it has released profile

Use the laptop to enable you to control the Service screen whilst inside the infeed table

Ther gripper setting jig is used to give an accurate and reliable zero to locate the gripper jaw to. Any piece of aluminium reinforcing box section will also work

Create a spreadsheet or a table to log your results,.

ng box section will also work Create a spreadsheet or a table to log your results,. <br/>) - Setting Motor Overload Relays + (It is important to set the Motor Overload … It is important to set the Motor Overload Relays to the correct values according to the motor as if the current is set too low, the motor will continually trip the MCB and if it set too high then the motor will not trip the MCB under fault conditions, leading to the motor burning out.ditions, leading to the motor burning out.)

- ZX5 Installation Procedure 2023 Part 2 + (Key data for installation of ZX5 Dokit to generate consistency of installation Quality checks for installation Manufacturing data supply)

- ZX5 Installation Procedure 2023 + (Key data for installation of ZX5 Dokit to generate consistency of installation Quality checks for installation Manufacturing data supply)

- ZX5 Installation Procedure 2023 Part 3 Guarding Conformity checks + (Key data for installation of ZX5 Dokit to generate consistency of installation Quality checks for installation Manufacturing data supply)

- Autocut Piece Jammed + (Let's say a small piece has become wedged … Let's say a small piece has become wedged between the eject table and the outfeed table frame.

ach into the machine until it is safe to do so - Press ESTOP</div> </div><br/>) - Assembly - R0000377B Mk11 Gripper + (Mk11 Gripper was designed to give a variab … Mk11 Gripper was designed to give a variable stop height position for the Mk10 gripper assembly. This is needed on systems with multiple chambers, where there is no "sweet spot" for the open grip position to suit all chambers. A Somatec turret stop is used to provide different stop heights

The design details are here [https://stugaltd.monday.com/boards/315478853/pulses/640717084 Design Notes]

853/pulses/640717084 Design Notes] <br/>) - Monday - Emails to Updates + (Mondays has changed the way it deals with … Mondays has changed the way it deals with the way it writes updates via email, in a very useful way for us. This will save a lot of time cutting and pasting information from emails. Simply put, * when you send an email, cc: the unique email address for the item in your email you are sending. This is standard practice to get your email into Mondays. * When your contact replies (with reply all) * their reply will now magically appear in the Monday update for the item. * It even strips out the email trail, leaving just the important reply It used to be the case that only members of Stuga.co.uk could send an email directly to an update, but this has now changed…ly to an update, but this has now changed…)

- R0000164 Spindle Disassemble for Required parts + (Obsoletion of main pcb tooling holder shaf … Obsoletion of main pcb tooling holder shaft has created inability to supply replacement spindle units that have failed on site. This procedure will extract required parts from failed units to provide a supply of parts required to create exchange units for R0000164 spindles

xchange units for R0000164 spindles <br/>) - Updating Teamviewer Host + (Older versions of Teamviewer are being pha … Older versions of Teamviewer are being phased out by the Teamviewer company from September 15th 2021. The advice on the website suggests you need to upgrade to version 15. However, v15 is not compatible with the older Windows XP machines in the field. The latest XP compatible downloadable version of the Host program is 13.2 and is available [https://download.teamviewer.com/download/version_13x/TeamViewer_Host_Setup.exe here] Regrettably, the update process on older versions is not simple, and frustratingly cannot be done remotely. It needs intervention from an operator at the machine with a small amount of technical know-how with a small amount of technical know-how)

- TB0301 Autoflow Saw Head Reinforcement - Additional Enhancements + (On Autoflow 2 Sawing Centres following 5 y … On Autoflow 2 Sawing Centres following 5 years of use., it has been found that the internal saw centre framework can lose its rigidity. this is probably due to "bruising" or denting of the aluminium joints introducing a slight amount of play. This is exacerbated by the design where it is attached and driven on from the base up A retrofit kit of parts has previously been created to allow additional reinforcement to be introduced within the structural framework. This kit builds upon the first kit to provide further accuracy enhancements by #Adding left right stability with additional slide rails at the top of the subframe #Adding front / back stability by moving the SY axis leadscrew to the same height as the saw table ====Parts required: ==== R0010272 Kit: Saw Frame Rigidity Pt 2 This kit consists of 2 carriage assemblies, specifically designed to provide further rigidity to the top of the Saw Head Assembly. In addition, 2 mounting blocks required to relocate the Saw Y Axis Assembly are also included. This allows the Saw Y Axis Assembly to continue to operate accurately, but improves the life of associated components. See also [[TB0259 Autoflow Saw Head Reinforcement]][[TB0259 Autoflow Saw Head Reinforcement]])

- Move SR Datum Sensor to Higher Level R0019217 + (On a Mk4 Autoflow, The SR axis daum sensor … On a Mk4 Autoflow, The SR axis daum sensor is originally located at the rear and to the base of the SR axis. This area is prone to offcuts, so a new location has been designed at the top, with the following design parameters

*Easy to retrofit

*Sensor is protected in a case

*Short distance to connection box

*Uses existing mounting holes

*Easy to adjust and maintain

*Sensing end location should be vertical onto a plate, not horizontal on to a radiused surface

*Can use E0000336 2mm range sensor reliably

*Incorporate a front fence to help deflect offcuts down the chute and to protect the sensor

The parts are supplied in Kit R0019217B

illustrated here are from a Right to Left feed machine. Parts are unhanded so can be fitted to either hand machine</div> </div><br/>) - ZX5 V Notch Blade Mechanical Setup + (On previous models the V notch separation … On previous models the V notch separation was set via the software. This could be quite time consuming and required multiple tests and measurements to get it right. Four variables were used for each V notch and it is not straight-forward to get the shape, depth and position correct. On the new ZX5 the '''shape''' of the V notch is set mechanically and once set it should never need changed again, but remember that some customers sharpen their V notch blades instead of replacing them. The following was carried out on the rear V notches using some standard outerframe but the process is exactly the same for the front. Once set you can use the usual software settings to increase/decrease depth and to align back to back. The overall process is: # Set the shape of the V notch (Mechanical adjustment) # Set the Depth of the V notch (Software adjustment in Notching Tab) # Set the Position of the V notch (Software adjustment in Notching Tab) you will be in close proximity to the V notch blades and tooling.</div> </div>)

- Setting Infeed Loading Wheel + (Setting the pressure and clutch tension on … Setting the pressure and clutch tension on the loading wheel is critical for the reliable and accurate running of the machine If set incorrectly, the profile will slip and not load correctly or will not give an accurate start position for the datum holes The goal is to set the system to a "goldilocks" zone where there is enough pressure and clutch tension to reliably load a bar, but not too much so the clutch limits any correctional movement from the gripper arm on loading e video demonstrates how easy it is for the wheel to become loose</div> </div>)

- Updating Baldor ESB Firmware 2022 + (Since 2022 ABB have removed the simple lin … Since 2022 ABB have removed the simple link from workbench to allow firmware download. This makes it trickier to upgrade an ESB unit on a saw side of a flowline to allow CANopen communication. This is needed on a Windows update. The procedure demonstrates where to find the firmware file and how to download to the ESB manuallyle and how to download to the ESB manually)

- 500mm Saw Blade Upgrade + (Step by step guide of how to carry out the … Step by step guide of how to carry out the 400mm to 500mm saw blade upgrade including long reach clamps. Time to complete is very dependant on condition of the machine, ie rusted or rounded off bolts which may need to be drilled out and holes re-tapped. Replace all screws with Loctite except grub screws on taper lock pulleys, grub screws for shafts on clamp pads and slit strip retaining screws or where a locking nut is used on cylinder rods.re a locking nut is used on cylinder rods.)

- ACEpc Changing IP address using netedit + (The ACEpcs use two different systems for c … The ACEpcs use two different systems for connecting a network #NETBeui - this was used on earlier machines but reliability depends on the customer network setup. Reconfiguration after initial setup is difficult #IP addressing - A setup system was written using IP addresses to connect. This is a little harder to set up, but is easier to change later. A special program called netedit was written which updates all the correct files in the backgroundes all the correct files in the background)

- Convert TC2 Project to TC3 + (The Beckhoff system provides a system for upgrading to TC3 from a TC2 project. This tutorial goes through the steps required to ensure the links and setup of the original TC2 project are copied through to TC3.)

- Guide to Fitting Eject Push Sensors on ZX Machines + (The Eject Push bar on the Saw Outfeed on t … The Eject Push bar on the Saw Outfeed on the ZX machines does not have sensors fitted to monitor the position of the cylinders. This causes an issue when the bar is obstructed and either does not fully extend or not fully extract. The cycle is not aware of the position of the cylinders and the machine will continue to run, often resulting in a collision. Not having sensors fitted also means that the Eject Push cycle is run via a timer. However, using a timer means that the system does not know the actual position of the cylinders. Having sensors fitted to the cylinders will allow us to have a cycle that monitors the position of the cylinders and we can determine the cycle has finished before allowing another operation to proceed. We can also use the sensors as feedback to stop the machine if the cycle fails. This will result in fewer collisions and damage to parts or products.

s and damage to parts or products. <br/>) - Beckhoff AX8000 Flowline Upgrade + (The Flowline range (Mk3, ZX3, ZX4) are Stu … The Flowline range (Mk3, ZX3, ZX4) are Stuga built and designed machines for prepping and cutting uPVC windows and doors. The Flowline is the first machine of the Stuga 'U' shaped machines which has prepping and cutting working in the same machine package. The Flowline is still a fantastic machine for the industry, however, due to the age of the machines and older control systems becoming obsolescent, we have had to find an upgrade route that does not only keep the machine going, but also provides improvements from the original model and up-to-date technology to future proof the machine. The upgrade that we have developed for the Flowline is supplied from an automation supplier named Beckhoff. We also use Beckhoff on our new build machines. This gives us better lead times, more understanding of the products and better diagnostics/ support for our customers. The drive system that we use is called the AX8000 series. These drives are a compact multi axis servo system that use an EtherCAT interface and STO safety functions. These servo drives, coupled with Beckhoff AM8*** series OCT servo motors provide quicker installations and all round performance increases from any system we have previously used. To drive all of the new system, we are using a Beckhoff IPC controller that runs TwinCAT 3. This links into the system via EtherCAT. All of the machine can now link together via EtherCAT to provide quick and stable communications. This tutorial will give you step by step guides on the physical upgrade requirements needed when upgrading a Flowline Mk3 to a Flowline Mk3 with Beckhoff AX8000 Control. Each step will provide you with written information and pictures to guide you through the upgrade. Each step will contain necessary information which will also provide you with rationale for the design and an idea of the benefits over using different methods. Please always feel free to provide Stuga with any feedback on this document or its contents.feedback on this document or its contents.)

- GE Control Components Changeover + (The GE control components are now obsolete … The GE control components are now obsolete and we have had to find a new manufacture to use. We have decided to go with Eaton control equipment for this. We are using the same supplier for these products and we have the added benefit if the supplier holding these parts in there stores. We had a choice to use either ABB, Eaton or Schneider components. Although all of the individual Eaton components are a direct replacement for the GE components, there are certain situation that we may be tripped up. This includes times when we need to change a motor breaker that has an auxiliary block connected to it. We can change the breaker but the GE auxiliary block will not fit on the new Eaton one. This means that the Eaton components need to have different part numbers to the GE components. This document will layout the new part numbers and what they relate to and instructions on how they are added and changed in the Sage system. are added and changed in the Sage system.)

- ZX5 MH Infeed Basic IO Test and Setup + (The MH infeed on a ZX5 is a module which c … The MH infeed on a ZX5 is a module which can be tested individually away from the fully installed machine. Once build stage is complete, to be able to test individually, the Infeed Module needs: - To be connected to mains power & be powered on - An air supply to the main blue line - Network connection (Network Cube) - HDMI & Keyboard dongle to be plugged into the Beckhoff PLC inside the cabinet. Input and output activation when testing the sole module is done through the Twincat project rather than through WinMulti The above is only required If the Machine is not fully installed and connected with power air and network already. The below guide is specifically for a fully installed and connected infeed.ically for a fully installed and connected infeed.)

- Autoflow Maintenance - Machining Centre + (The Machine has many moving parts, all which need regular maintenance. Below outlines what items need particular attention:)

- Autoflow Maintenance - Sawing Centre + (The Machine has many moving parts, all which need regular maintenance. Below outlines what items need particular attention)

- Autoflow Maintenance - Outfeed Table + (The Machine has many moving parts, all which need regular maintenance. Below outlines what items need particular attention)

- Stuga Product Database - Edit Product Data + (The Stuga website has a parts database, much like a shop front for helping identify Stuga Machine parts. Keeping the data updated and logging nuggets of useful information is invaluable in helping identify parts on machines)

- Updating Beckhoff TwinCAT3 Backend Version + (The TwinCAT3 beckhoff systems have a speci … The TwinCAT3 beckhoff systems have a special version of TwinCAT installed - the "Runtime" version XAR (eXtended Automation Runtime). This differs from the full "Engineering version XAE that is installed in the front end and camera PCs in that it is the bare bones of TwinCAT for machine running purposes. '''It does not have the Visual Studio editor in it.''' The runtime version may need updating to 3.4024.xx to allow the latest front end and PLC code to work the latest front end and PLC code to work)

- TB0447 ZX5 Setup - X Axis Beam Calibration + (The ZX5 has a moveable Beam on the Z axis. … The ZX5 has a moveable Beam on the Z axis. The design reason behind this is to keep the gripper arm short for reliability and stiffness, yet enable it to move out of the way for rear V notching During the calculations for the machining bar recipe, the software has to work out if and when the beam needs to be moved: · If there are no v notches on the bar, then machine all the operations without moving the beam. Beam moves at the very end when ejecting · If there is a V notch, move the bar during the first X axis position where position > beamStrokeLength Therefore, it is very important for the software to know how far the beam moves physically to offset all the positions to allow for it. The distance is measured and entered into parameter beamStrokeLength. It should be around 700mm. beamStrokeLength. It should be around 700mm.)

- ZX5 Alignment Check + (The ZX5 machine can be tricky to align as there are many adjustments designed into the table to offset manufacturing tolerances. This step by step guide follows the correct protocol to ensure the starting point and sequence of alignment is correct)

- Repairing R axis datum pin + (The datum pin on the old ZX4 at Sidey was … The datum pin on the old ZX4 at Sidey was recommended to be changed at my last service visit. Unfortunately there are quite a few different datum spindle plates and we were having problems tracking down the correct one so it was decided that I would be sent out the new replaceable datum pin carrier as Sidey have a small machine shop I could use to modify the existing plate to make it fit. Unfortunately the mounting holes of the new carrier interfered with the mounting holes of the pneumatic cylinder so it couldn't be used. After taking dimensions of the existing plate for identification I realised there was actually a very small and quick repair that could be carried out until the correct parts were identified. All you need is a cordless drill, a 2.5 and a 3.1mm drill, M3 tap and an M3 x 15mm cap head screw.l, M3 tap and an M3 x 15mm cap head screw.)

- TM018B Microline and ZX3 V Notch Blade Setup + (The engineer will need a reasonable mechan … The engineer will need a reasonable mechanical knowledge, and a working knowledge of the operation of the machine. You will need callipers (+/-0.05mm) and an accurate rule The setting of the V notch blades on a ZX3 Ring revolves around the setting of two groups of parameters: *V and W axis positions *Blade offsets for each blade The rough position of V and W axes is set first, then the individual blade offsets are set, and finally a test is run to tweak the accuracy to gain perfection. There are two “tweaking” parameters for each blade. The two parameters are: *Depth offset – how deep into the bar *X axis offset – position of point of blade relative to the spindle centrelinef blade relative to the spindle centreline)

- TB0422 Commissioning ZX5 Software 2018 + (The first step in commissioning a new mach … The first step in commissioning a new machine is to get the basic software setup correctly installed. Because the software is designed to be very flexible across many machine types, the simplest way to do this is to copy from a recently built similar machine.opy from a recently built similar machine.)

- R0000299 Stroke assembly rebuild Part 2 + (The following instructions should be follo … The following instructions should be followed to ensure that correct assembly and setting are performed '''Tools / consumables Required''' Standard hex key set Standard spanner set Large adjustable spanner Drifts and punches Ballpein hammer Soft hammer FE10 Solvent Hylomar Gasket '''Parts Required''' Kit R0000299 containing B0000043 Double Angular bearing 15 I?D 35 O?D 15.9 long rubber seal 3 x 2 B0000105 Double Angular Bearing 15 I/D 35 O/D 15.9 Long x 1 B0000335 3ph Brake motor 2 pole 3000rpm x 1 B0000380 Double Angular Bearing 25 I/D 52 O/D 20.6 Long + rubber seal x 2 D0000059 Damper Bridge x 1 D0000062 Damper Bridge Boss x 2 D0007730 ZX4 V Notch Mk1 Spindle Shaft x1 D0007867 Bevel Gear (Left) x 1 D0007868 Bevel Gear (Right ) x 1 D0007873 Motor Gear x 1 D0007874 Pinion Gear x 1 D0007875 Pinion Shaft x 1 P0000165 damper x 174 Pinion Gear x 1 D0007875 Pinion Shaft x 1 P0000165 damper x 1)

- Stuertz Infeed - Align and dowel GX rack + (The rack on a Stuertz infeed is a helical … The rack on a Stuertz infeed is a helical type and is supplied unpinned, as the motor is not connected before delivery to Stuga The alignment must be checked then dowelled with 5mm roll pins The racks are already located in the "Y" direction with location pins, this procedure is purely to align the racks to each other in the GX directionhe racks to each other in the GX direction)

- VM Upgrade Hardware + (The upgrade is to prep the machine ready for adding a Virtual Mahine (VM) to the setup.)

- WinMulti - Changing The Colour Identification Box + (The version 6 software has a feature to id … The version 6 software has a feature to identify the colour of the profile and also to help operators load foiled profile in the correct orientation.

Updating the colours is a very simple job that can be done in 2 ways

# Via the Machine Settings->Colours Tab # From Bar Queue whenever a new colour is encountered.

Queue whenever a new colour is encountered. <br/>) - Diagnosing EtherCAT Issues - Advanced + (There are many tools available to help tra … There are many tools available to help trace EtherCAT faults. This document describes some more advanced features that can help pinpoint an intermittent or hard to find issue. You will need a good working knowledge of the machine and the basis of EtherCAT networking See Also [[TwinCat Connection Faults]][[TwinCat Connection Faults]])

- Recovery of Bar Queue following winMulti Crash + (There have been cases of software crashing … There have been cases of software crashing on the Stuga front end software, but the machine will continue to cut the holes and slots on the bar and eject it to the transfer table. This creates the situation that the bar is physically finished, but the software has not registered it as finished. This can lead to confusion for the operator and put the bar queue out of sync, which can lead to wasted profile of sync, which can lead to wasted profile)

- Gripper Push Speed on Flowline and ZX + (There is a cylinder called Grip push, when … There is a cylinder called Grip push, when bar is moved to its unload position the Gripper Comes OFF then Grip push is activated to push the profile of the gripper to clear ready for the Eject push onto transfer Table. The video shows what happens if the grip push is set too fast. The speed of the cylinder is Far too Fast and is Throwing/punching back down machine. -- This needs to be slowed Down. machine. -- This needs to be slowed Down.)

- PLC Source Control - Adding a Repository + (These instructions give details of how to … These instructions give details of how to set up a repository so that any changes made to the core project will be tracked. For the git source control to work it is important that GIT has been chosen as the source control program. see Prerequisits. The instructions start from : The project has been created and PLC code has been loaded in to the TwinCAT Xae Shell program.oaded in to the TwinCAT Xae Shell program.)

- PLC Source Control - Working with GIT and TcXaeShell + (These steps outline typical actions that make up a development cycle for changing code on a machine, saving changes locally and saving to the cloud repository using Git as the Source control tool.)

- Alignment guide using wire line + (This dokit is to help with the use of a wi … This dokit is to help with the use of a wire line to set alignment correctly on mechanical build up. Using a wire line correctly will ensure a very accurate straight line is achieved . Accuracy of + - 1 mm over any distance can be achieved using the following method. Using one incorrectly can also easily be done.! The steps shown can be applied to all types of alignment , when you have a vertical face on components that require aligning. face on components that require aligning.)

- Units of Measure modification CIM50 + (This guide is to show how to amend units o … This guide is to show how to amend units of measure of existing stock items. If a new product is created please ensure the Units of measure is always set up correctly from the beginning . The CIM50 guide for Units of Measure setup is [https://cimservices.sharepoint.com/:w:/s/Cim50PartnerMarketing/EZhA_HF6SFJLmkVO5WANYXIBZdMx4hbVnuY3cdIF78p7lg?rtime=FcNQz7GE2Ug here]4hbVnuY3cdIF78p7lg?rtime=FcNQz7GE2Ug here])

- Allocations + issuing received parts + (This involves splitting down received orde … This involves splitting down received orders into the JC/Pick bins the parts have been allocated to by Sage. If there are parts to be allocated, after filling in the 'this delivery' column and pressing save, if there are parts to be allocated a list will appear. this list is in order of part number and in the sub-screen after highlighting each part number the specific Job card numbers will show quantities required for each bin and also the quantity to be allocated from the order received.y to be allocated from the order received.)

- Ecoline - Setting V Notches on winMulti Software + (This is the full setup procedure for V not … This is the full setup procedure for V notches on an Ecoline. This should only be needed on initial commissioning or if the shape of the notch has changed due to some physical intervention, for example -

- Blade Change

- Blade buckled

here is no sense carrying on because you cannot complete this setup unless the machine is consistent and reliable</div> </div> <br/>) - Importing Picking List from Sage To Monday +

- Flowline 6 to 6o5m Extension + (This procedure describes how to upgrade a … This procedure describes how to upgrade a flowline to increase the standard capacity from 6.0m to 6.5m. The procedure involves extending the machining centre outfeed travel and saw infeed travel base to 6.0m to cope with a longer rail on each side. These are generally supplied as a new part. Other ancillary parts that will need extending * Cables * Energy Chainsl need extending * Cables * Energy Chains)

- ACEpc Installing netedit with NetSetGo disk + (This procedure will completely overwrite a … This procedure will completely overwrite any data on the hard drive of the ACEpc.

This is not a problem on a flowline where the data resides on the main MH hard drive in a shared directory c:\saw.

If this process is to be carried out on a standalone saw or router, make sure the data is backed up first.

e sure the data is backed up first. <br/>) - Setting Up C0000422-KIT - Full Hardware 2023 + (This process takes the components to creat … This process takes the components to create a standard "C000422-KIT". This kit can then be stored and pulled off the shelf when required. It will then need to be set up for the particular customer machine using [[Setting Up Windows PC C0000422-KIT 2023]] =Notes= *There are two PCs running on the same hardware, The Host PC and the Virtual machine. **'''Host PC''' (For support) ***The base Windows install running directly on the hardware installed to Dell NVME drive. ***Has its own OEM Windows license supplied by Dell linked directly to the hardware (no product code – stored in the Dell hardware) ***Imaged by Macrium reflect. **'''Virtual PC – Stuga VM''' ***Used for Stuga software - the VM can run on any PC without changing drivers, etc. Host OS version / hardware unimportant as long as it runs Hyper-V. ***A second install of Windows running on a virtual machine, hosted by the Host PC above. It has a dedicated SSD (the Kingston Drive) stored on [:Fichier:///D:/VMPC.vhdx D:\VMPC.vhdx], with 8GB RAM. ***Has its own dedicated Windows 11 PRO license present in the kit, product code stored on Monday and on the license. ***Copied to host and setup manually during install. There is a setup program for the specific client after this process has completed: '''P_Stuga_P… '''on the desktop of the host.'P_Stuga_P… '''on the desktop of the host.)

- Dokit - Creating A Work Instruction + (This tutorial guides you in how to create … This tutorial guides you in how to create Work Instructions in Dokit and to avoid the pitfalls.

If the Work Instruction is already created, follow the process [[Dokit - Editing Work Instructions]]

= Warnings =

a fa-exclamation-triangle"></i></div> <div class="icon-instructions-text">...Do not publish anything inflammatory, offensive or illegal</div> </div><br/>) - ZX5 Transfer Table Crank set up + (This tutorial will show you how to mechani … This tutorial will show you how to mechanically set up the cranks and sensors so that the correct overlaps between the different cranks are achieved. Crank C is the crank on the Machining Centre Outfeed that controls the single pop up. Crank D is also mounted on the Machining Centre Outfeed and controls the pop ups on the Transfer Table. Crank E is the crank on the Saw Infeed and controls the single pop up that moves the profile in to the channel. that moves the profile in to the channel.)

- Fitting Zx5 Crank Upgrade + (This upgrade replaces the crank arm assemb … This upgrade replaces the crank arm assemblies on Z065, Z066 and Z067 with a direct drive system to improve reliability

This procedure involves mechanical fitting, electrical wiring and help from a TwinCAT3 competent engineer at HQ for software changes

></div> <div class="icon-instructions-text">...Motors must be rewired for Delta and NOT Star</div> </div> <br/>) - R0010309 Ecoline Ultrasonic Material Loaded Upgrade + (Upgrade of load sensor For infeed table on … Upgrade of load sensor For infeed table on Ecoline machines

'''Component list'''

A0001046 P Clip 6mm Steel / Rubber Liner x 2

D0010973 Material Loaded Sensor Plate x 1

E0001104 PreMade Cable: M8 Socket 4 Way Cable 5m x 1

E0001120 Sensor: Ultrasonic M8 20-150mm x 1

M0001053 Copper Tube 6mm x 4.4mm 10m Coil x 0.3

P0000046 Fitting: 'Y' Adaptor 6mm x 1

P0000069 Tube to tube fitting 6mm x 1

P0000160 Fitting: Flow Controller In Line 6mm x 1

000160 Fitting: Flow Controller In Line 6mm x 1 <br/>) - Upgrade Autoflow to Windows 10 + (Update 2024 - Upgrades now consist of a ne … Update 2024 - Upgrades now consist of a new Windows 11 PC with VM for the front end and a C6017 PC for the back end.

Upgrading an Autoflow to Windows 10 involves upgrading two PCS

#The Beckhoff control PC - replaced with a C0001225-KIT

#The Camera PC - replaced with a C0000422-KIT with a VM setup. this now becomes the front end PC

=== For Historical reference, these are the pre-2024 notes: === ''Upgrading an Autoflow to Windows 10 on site involves upgrading two PCS'' #''The Beckhoff control PC'' #''The Camera PC'' ''

The Beckhoff PC is not upgradable so needs to be completely replaced. We use the miniature [https://www.beckhoff.com/english.asp?industrial_pc/c6017.htm Beckhoff C6017] for this'' ''It is not cost effective to upgrade and old camera PC, so a new one is supplied'' ===''Notes''=== *''The Beckhoff PC is now powerful enough to run the front end and back end.'' *''The camera PC is there to replace the camera PC on site and contains the storage for the machine cameras'' *''Because the Beckhoff PC has limited hard drive space, the DDRIVE will be on the cameraPC''hard drive space, the DDRIVE will be on the cameraPC'') - Filling Out An Online Daily Timesheet Form + (We are using Monday.com to handle daily ti … We are using Monday.com to handle daily timesheet entries. The layout of the form has been designed to make data input as minimal as possible. We are looking to improve accuracy of time capture, cut down administration time and to make historical data available without the need to store paperwork or take pictures. You will only be able to view and edit your timesheet when logged into your Monday.com account. Other employees are unable to see your data.her employees are unable to see your data.)

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português