Procedures for Daily, Weekly and Monthly Maintenance on Autoflow Sawing Centre Module

Difficulté

Moyen

Durée

2 heure(s)

Sommaire

- 1 Introduction

- 2 Étape 1 - Horizontal and Vertical clamps

- 3 Étape 2 - Check Rear Fence Alignment

- 4 Étape 3 - Stainless Steel Bed

- 5 Étape 4 - Saw Blade Area

- 6 Étape 5 - SZ Axis Saw Up / Down Drive

- 7 Étape 6 - Saw Tilt Rollers

- 8 Étape 7 - SR Axis Slewing Ring and Pinion

- 9 Étape 8 - SY Axis Linear Rails

- 10 Étape 9 - Extraction Separator

- 11 Commentaires

Introduction

The Machine has many moving parts, all which need regular maintenance. Below outlines what items need particular attention

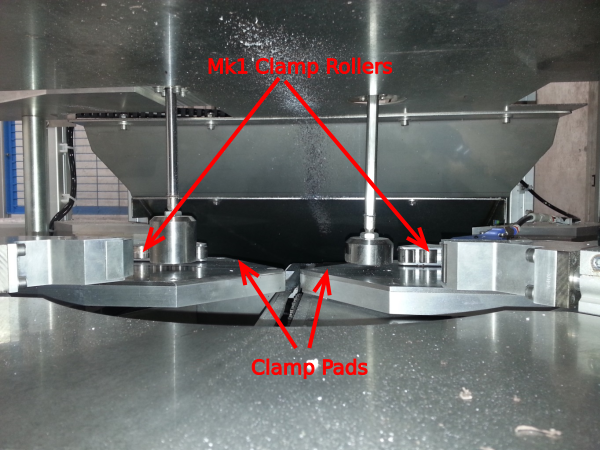

Étape 1 - Horizontal and Vertical clamps

- Remove any debris from clamp pads and rollers

- Visually check the rollers and clamp pads for damage or excessive wear, oil rollers with supplied oil, visually check cylinder rods for damage

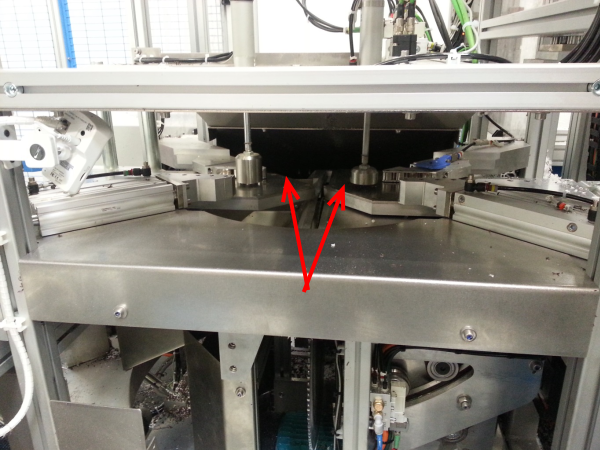

Étape 2 - Check Rear Fence Alignment

Using the supplied straight-edge, check the backfence alignment through machine.

Misalignment is the normat cause of inaccuracy issues

Étape 3 - Stainless Steel Bed

Use a suitable foam cleaner for cleaning off the glue and tape residue left by the profile rolling along the beds

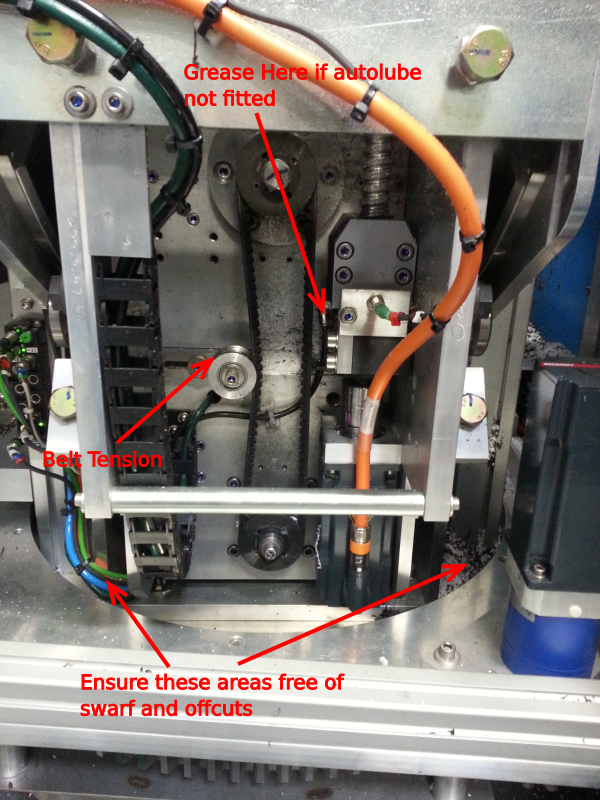

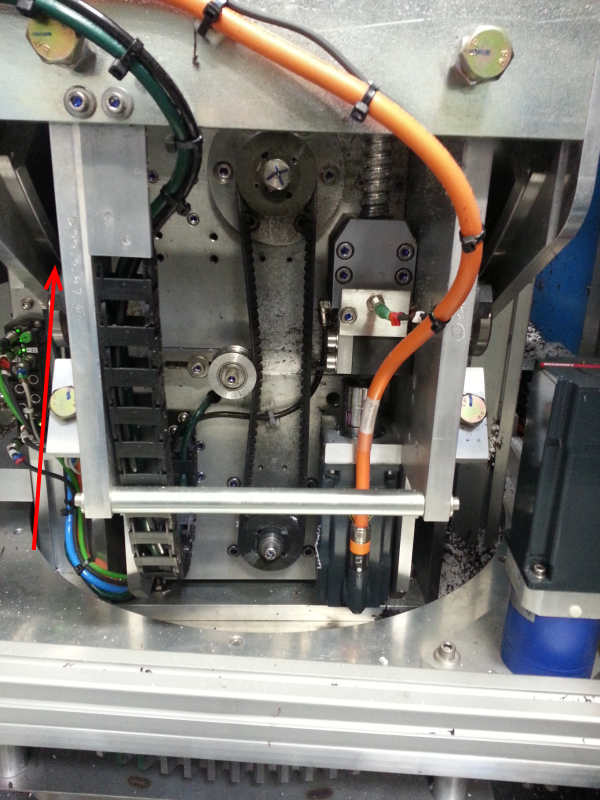

Étape 5 - SZ Axis Saw Up / Down Drive

- Check that the drive belt is free from wear or any cuts / nicks along the circumference of the belt

- Ensure that the drive belt has sufficient tension via the tension roller

- Check the leadscrew for any wear or damage

- Grease with 1 Pump if lubricator not fitted

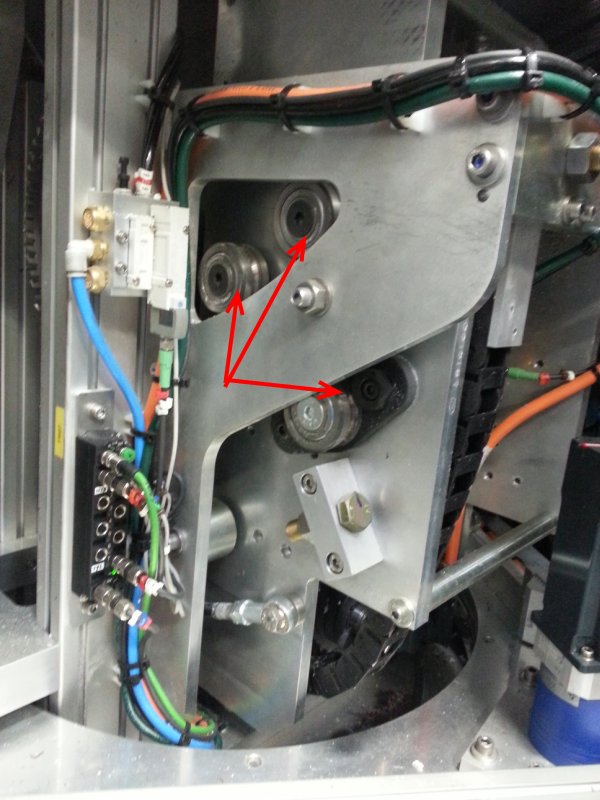

Étape 6 - Saw Tilt Rollers

- Check rollers and runner surface for damage or wear

- Lightly oil rollers and runner surface

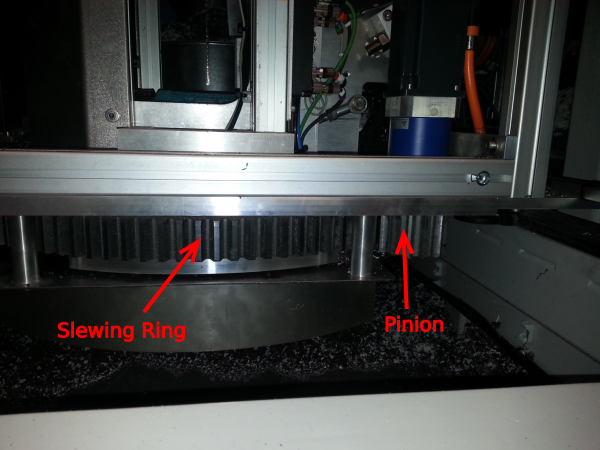

Étape 7 - SR Axis Slewing Ring and Pinion

- Visually check pinion wheel and slewing ring for any damage, chips or cracks

- Remove any debris that may have become caught up in the teeth

- Turn assembly through full range of movement to check for any tight spots

- Grease ring on grease points. 1 Pump each

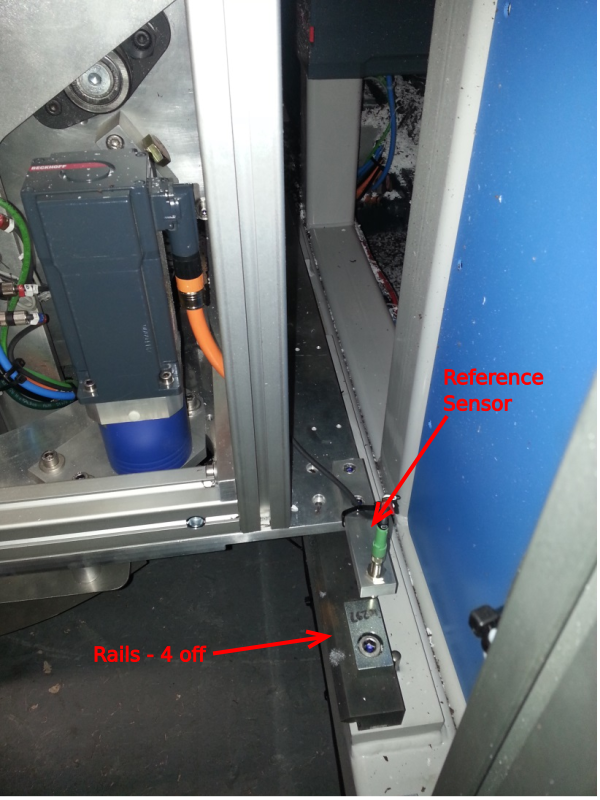

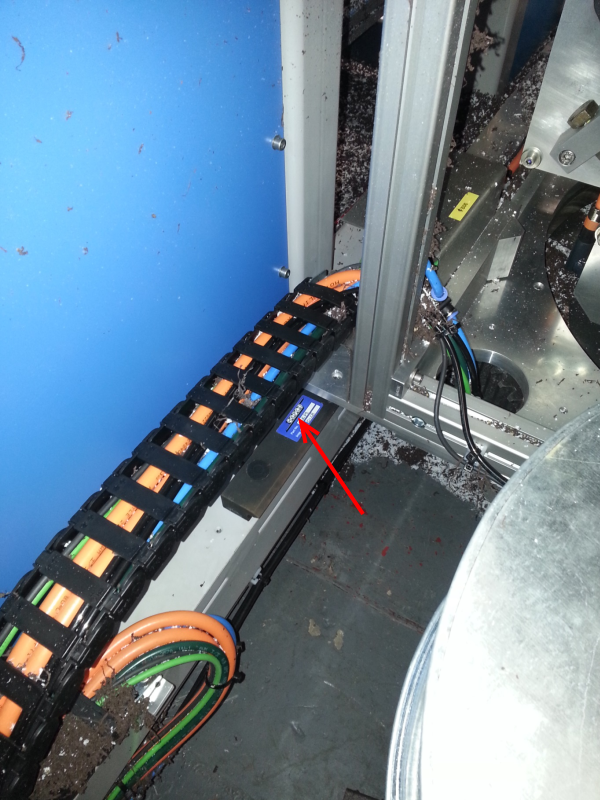

Étape 8 - SY Axis Linear Rails

- Lightly oil rail surface with supplied oil

- Ensure reference sensor is not damaged

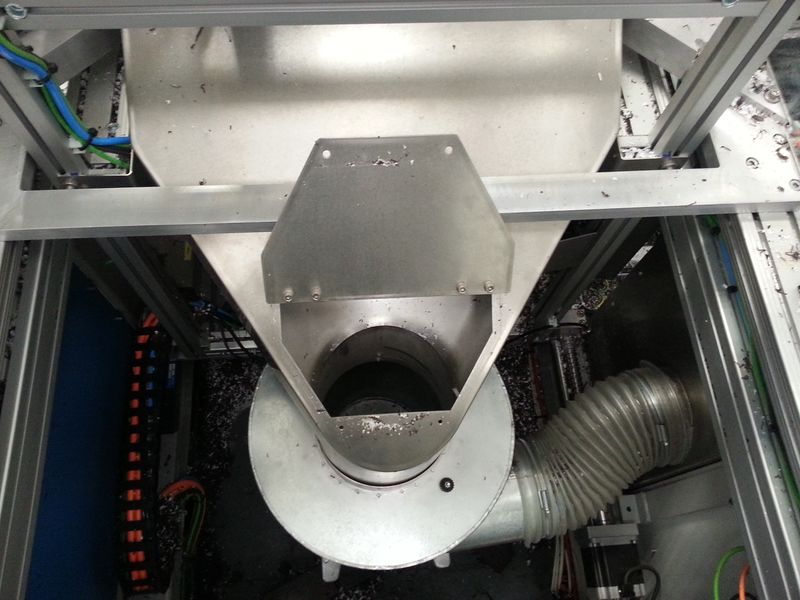

Étape 9 - Extraction Separator

Ensure that the Hose and Chute are not blocked by large offcuts

Check Hose for damage / cuts – replace if necessary

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português