How to check the parallelism of the Stuertz Infeed - GY axis position to backfence

Sommaire

- 1 Introduction

- 2 Pièces et outils

- 3 Étape 1 - Ensure a zero GY position at datum

- 4 Étape 2 - Ensure infeed Datum roller aligns with backfence

- 5 Étape 3 - Find range of Adjustment

- 6 Étape 4 - Move the GX axis to a measure position

- 7 Étape 5 - Move GY axis to locate

- 8 Étape 6 - Log GX value vs the GY value in your table / spreadsheet

- 9 Étape 7 - Repeat for different GX axis positions

- 10 Étape 8 - PASS or FAIL

- 11 Commentaires

Introduction

It is important that the parallelism of the GY axis to the backfence is set and maintained along the length of the rack. This tutorial describes how to check this parallelism without the need for measuring equipment

General Procedure

- Find range of adjustment required

- Zero GY axis to ensure range adjustment can be met

- Move to straight edge resting points, Adjust rollers at these points

- Use straight edge between resting points to adjust the other rollers to a fixed datum

Potential Symptoms of a problem

- Gripper cannot pick up offcuts

- Gripper /profile end forced away from backfence

- Accuracy problems

- Gripper wobbles after it has released profile

Use the laptop to enable you to control the Service screen whilst inside the infeed table

The gripper setting jig is used to give an accurate and reliable zero to locate the gripper jaw to. Any piece of aluminium reinforcing box section will also work

- Pièces et outils

Pièces et outils

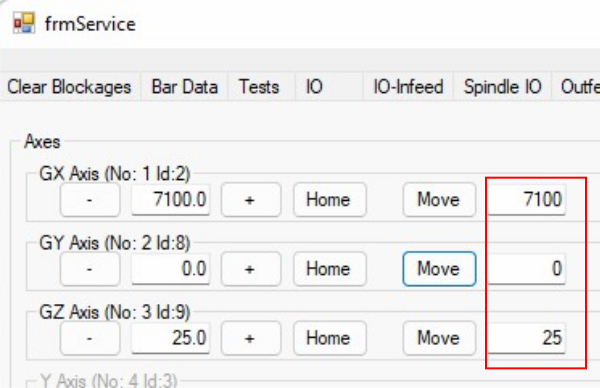

Étape 1 - Ensure a zero GY position at datum

- Datum the machine and move GY axis to zero, GZ to 25

- Place the jig against the backfence and offer it up to the Gripper Jaw

- If the GY datum is set correctly, the rear outer face of the jig should be just in contact with the rear serrated jaw

- If this is not the case, set GY datum correctly

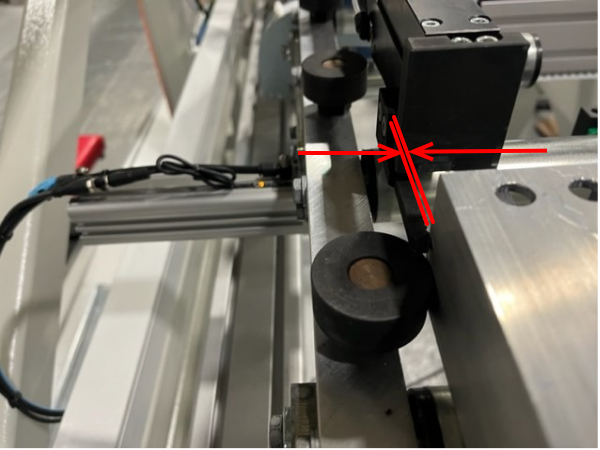

Étape 2 - Ensure infeed Datum roller aligns with backfence

Using the straight-edge, ensure the infeed rollers are 0-1mm behind the machining centre datum rollers .

Étape 3 - Find range of Adjustment

- With the GY at zero, move the GX axis to the last roller before machining centre

- Check the gripper position relative to backfence

- Check to see if this is within the adjustment range of the infeed roller

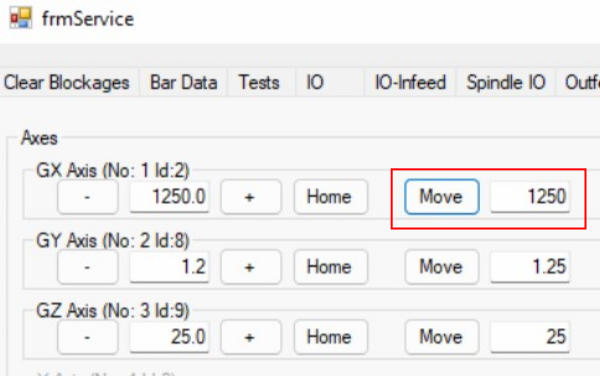

Étape 5 - Move GY axis to locate

If the backfence to gripper is different in this location, it will be visible by a gap or interference to the jig

Move GY axis (in 0.25mm increments) to make it touch

Log GX value vs the GY value in your table / spreadsheet

Étape 7 - Repeat for different GX axis positions

There may be areas where the offset changes more than others - these deserve more detailed inspection with closer GX axis increments

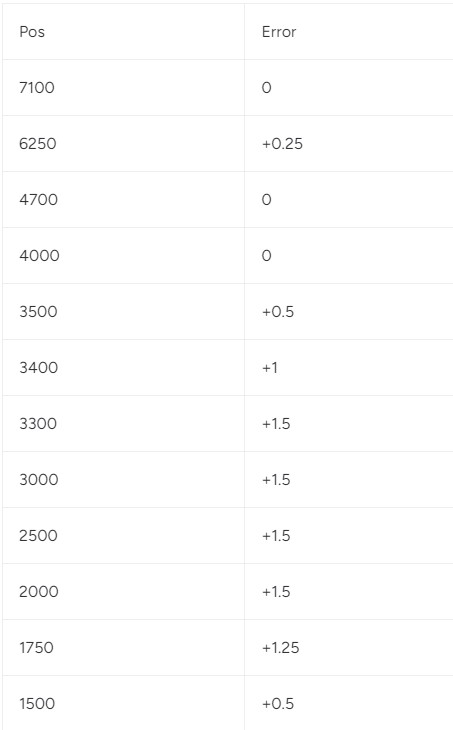

Étape 8 - PASS or FAIL

PASS

The error should be within +/- 1mm along the rack

In the given example of measurements, the overall range was 0 to +1.5mm

Therefor the GY axis datum should be adjusted by+0.75mm so the error range will then be -0.75mm to +0.75mm(within tolerance

FAIL

If the error variance is outside this range, the backfence will need to be rest to correct this

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português