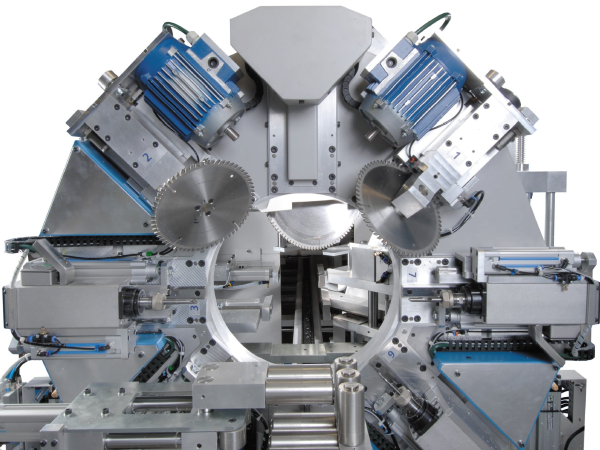

ZX3/Microline/Flowline ZX3 V Notch Blade Setup This module guides the engineer on how to correctly set the V notch blades

Introduction

The engineer will need a reasonable mechanical knowledge, and a working knowledge of the operation of the machine.

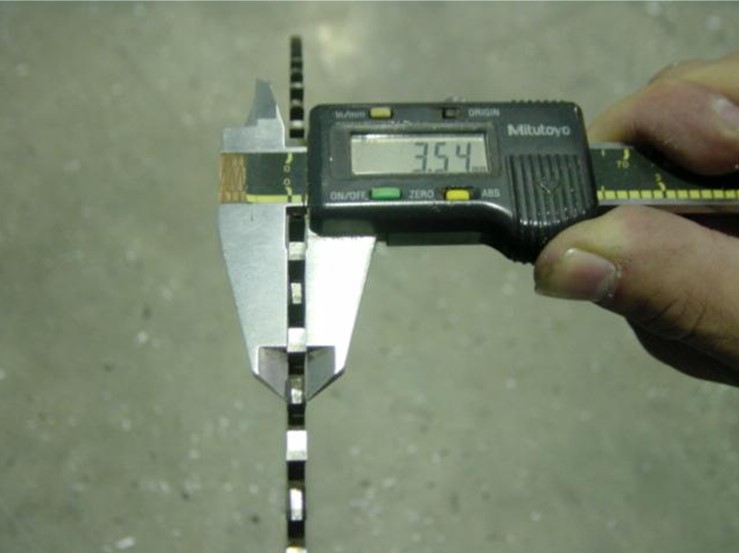

You will need callipers (+/-0.05mm) and an accurate rule

The setting of the V notch blades on a ZX3 Ring revolves around the setting of two groups of parameters:

- V and W axis positions

- Blade offsets for each blade

The rough position of V and W axes is set first, then the individual blade offsets are set, and finally a test is run to tweak the accuracy to gain perfection.

There are two “tweaking” parameters for each blade. The two parameters are:

- Depth offset – how deep into the bar

- X axis offset – position of point of blade relative to the spindle centreline

- Pièces et outils

Pièces et outils

Étape 1 - Before You Start

- Make sure the Datum is correct first.

- V notch blades are not buckled.

- Check that the profile width is correct for the profile you are testing.

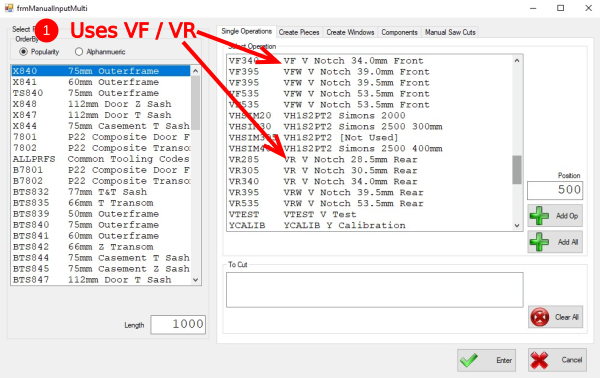

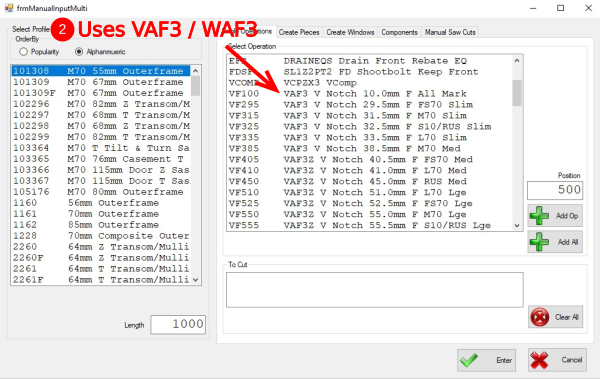

Find out which V Notch files the machine is using by checking the operation setup. A simple way of doing this is shown in the pictures by starting a "Manual Input".

Picture 1 - shows this machine uses VF / VR codes

Picture 2 - shows a different machine using VAF3 codes

Note this "mnd type" for later

Étape 2 - Run a VTest

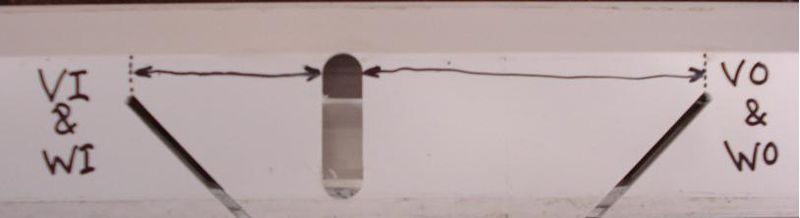

A calibration mnd file has been written to help line up the x offsets called VTEST. This program creates the following pattern on the bottom of the profile using a 10mm spindle and the notching blades themselves:

Run the VTest operation on a length of large outer frame of at least 1m long. Put the operation at a position of 500mm.

The pattern allows you to measure the offsets required with calipers.

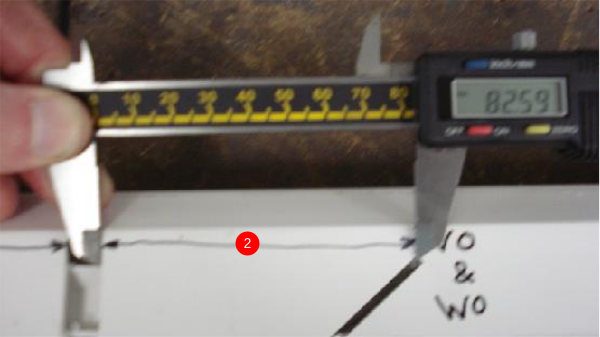

Étape 3 - Measure Results for x Offsets

- Measure between the VI blade and the edge of the 10mm slot – This value is the xoffsetVI (and also the xoffsetWI). (We need to add 5mm to the measured Value). 50.33mm

- Measure between the VO blade and the edge of the 10mm slot – This value is the xoffsetVO (and also the xoffsetWO). (We need to add 5mm to the measured Value) 87.59mm

Étape 4 - Update the Parameters for xOffsets

- Set the xOffsetVI and WI to the new value settings. THIS VALUE IS ALWAYS POSITIVE

- Set the xOffsetVO and WO to the new value in settings. THIS VALUE IS ALWAYS NEGATIVE

Depending on the software version, there are 4 places where these settings are stored / edited

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português