Procedures for Maintenance of the Autoflow Machining Centre Module

Difficulté

Moyen

Durée

2 heure(s)

Sommaire

- 1 Introduction

- 2 Étape 1 - Infeed Clamp Vertical and horizontal rollers

- 3 Étape 2 - Spindle Motors

- 4 Étape 3 - V Notch Axis Gearboxes

- 5 Étape 4 - Slewing Ring and Pinion wheel

- 6 Étape 5 - R Axis Datum Assembly

- 7 Étape 6 - Y Axis Rails

- 8 Étape 7 - Outfeed Clamp Vertical and Horizontal Rollers

- 9 Étape 8 - Z Axis Linear Bearings

- 10 Étape 9 - Auto lube System

- 11 Commentaires

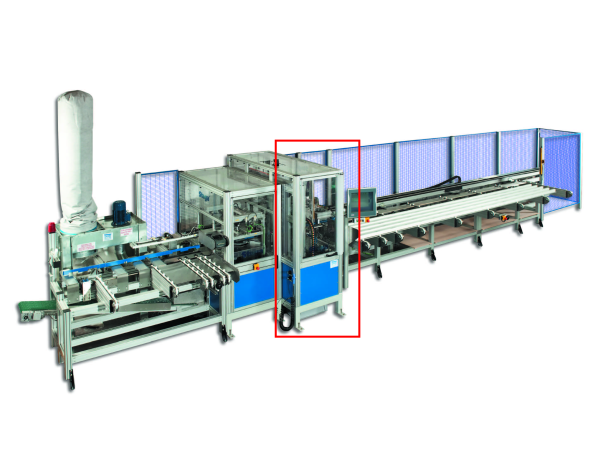

Introduction

The Machine has many moving parts, all which need regular maintenance. Below outlines what items need particular attention:

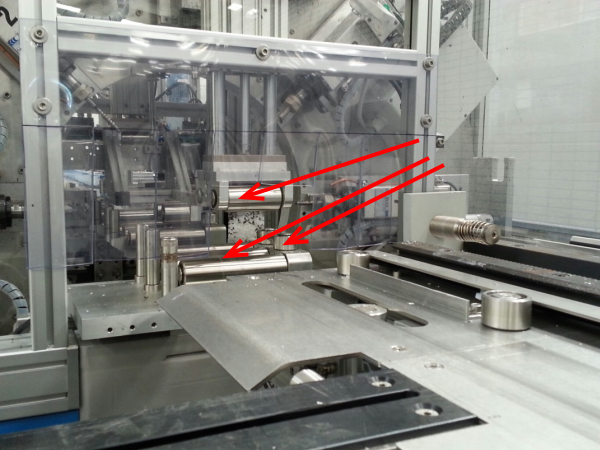

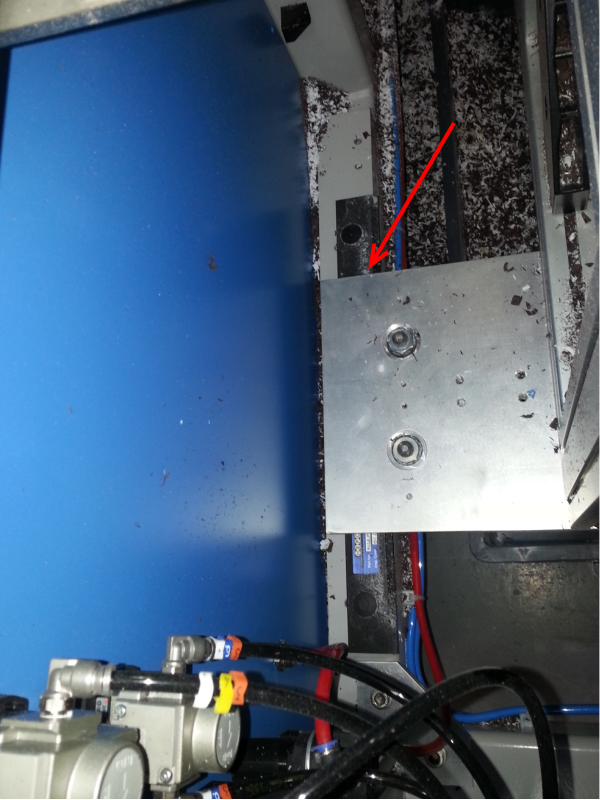

Étape 1 - Infeed Clamp Vertical and horizontal rollers

- Remove any tape or debris which may have become entangled in the rollers.

- Apply oil to top and side of roller units and then slowly spin them for a few revolutions to allow the oil to penetrate the bearings

- Lubricate slideways and shafts

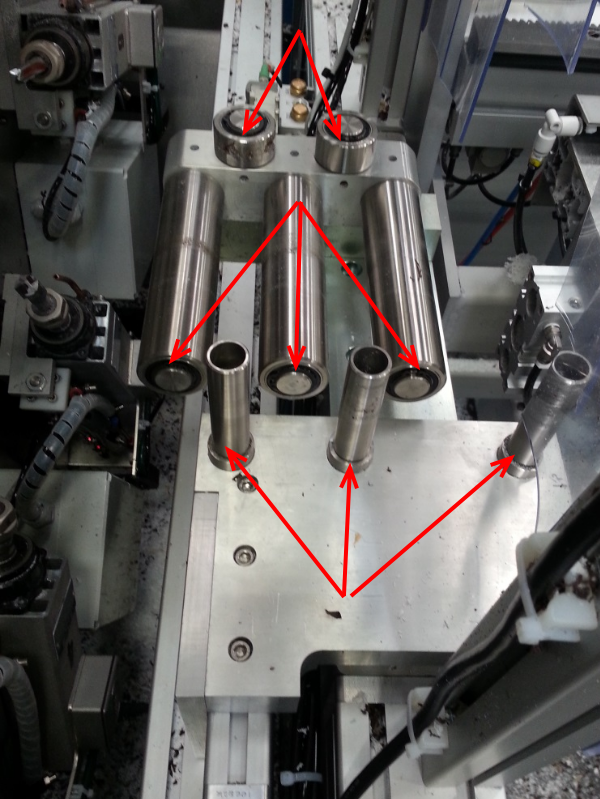

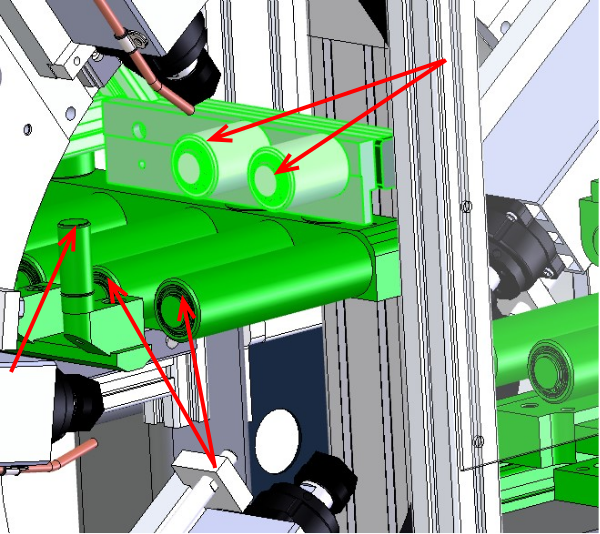

Étape 2 - Spindle Motors

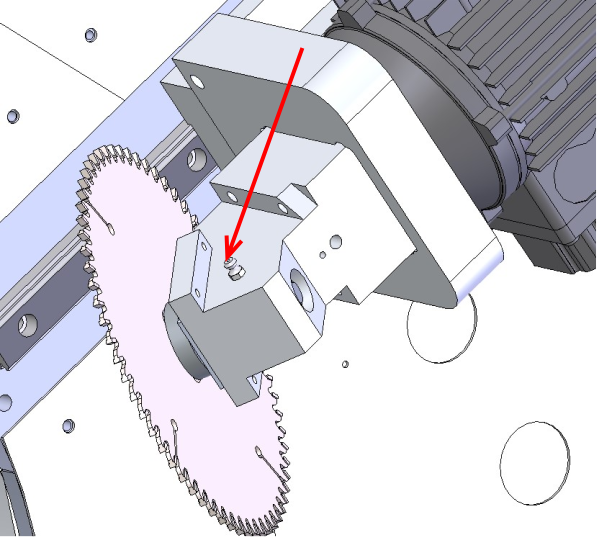

- Ensure that each spindle will turn freely with no grinding noise when rotating, check cutters for chips or damage, check V – Notch blades for chipped or damaged teeth

- Check Spindles slide freely in and out on full range of movement

- Check Electrical trunking

- Lubricate slideway bearings

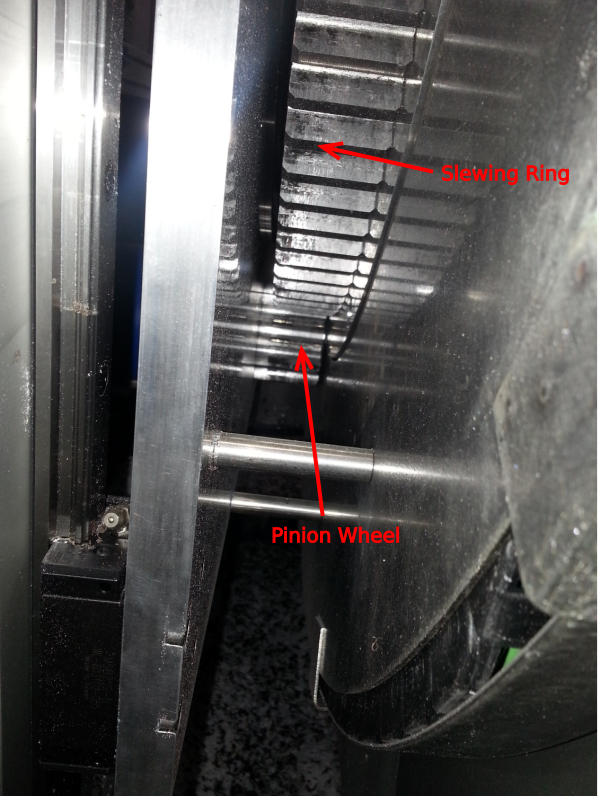

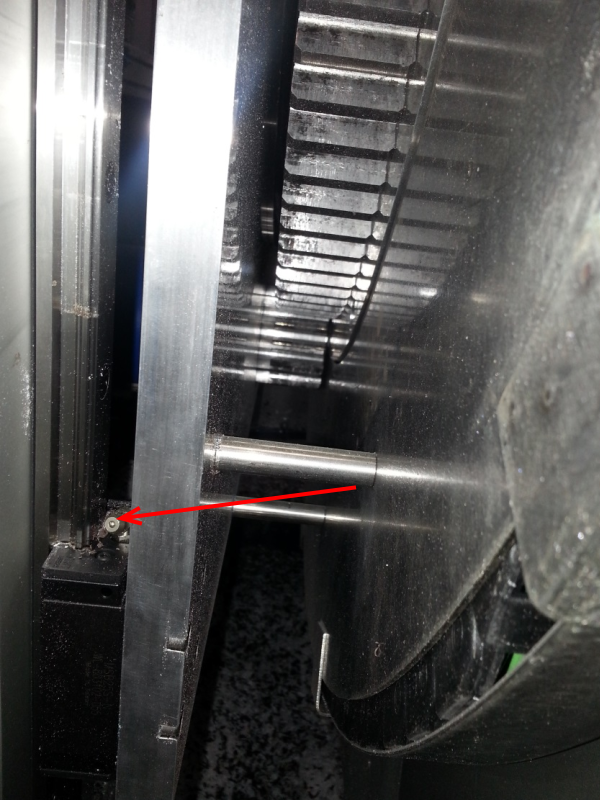

Étape 4 - Slewing Ring and Pinion wheel

Visually check pinion wheel and slewing ring for any damage, chips or cracks, remove any debris that may have become caught up in the teeth

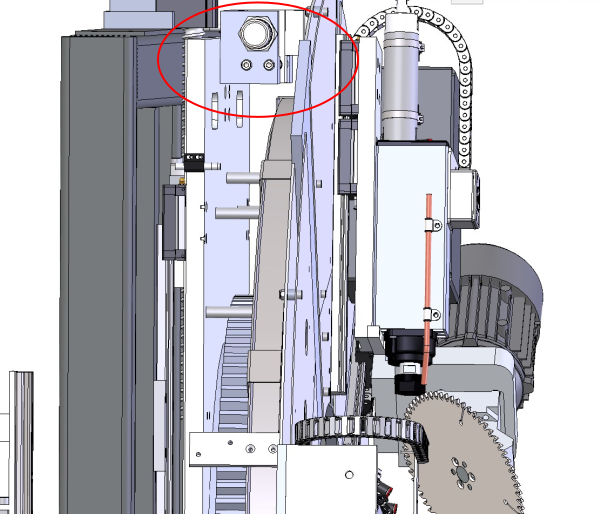

Étape 6 - Y Axis Rails

4 off Located at the bottom of the machining centre cabinet.

Clean away any debris

Lightly oil rail surface with supplied oil

Étape 7 - Outfeed Clamp Vertical and Horizontal Rollers

- Remove any tape or debris which may have become entangled in the rollers.

- Apply oil to top and side of roller units and then slowly spin them for a few revolutions to allow the oil to penetrate the bearings

- Lubricate slideways and shafts

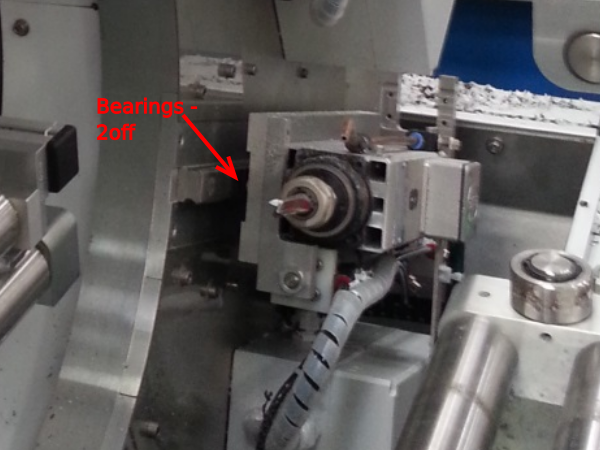

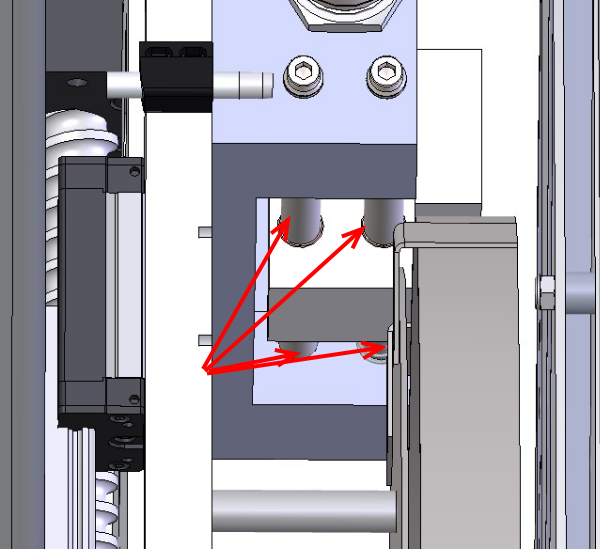

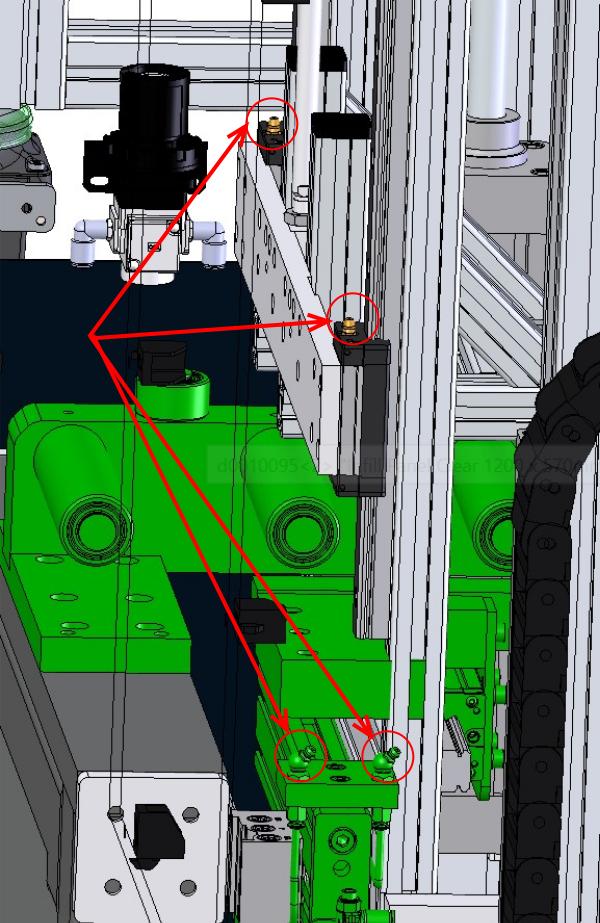

Étape 8 - Z Axis Linear Bearings

4 off

1 – 2 pumps of grease via grease nipple, wipe away any excess grease

Étape 9 - Auto lube System

Check level of grease in Auto lube

Part replacement order code is M0001047

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português