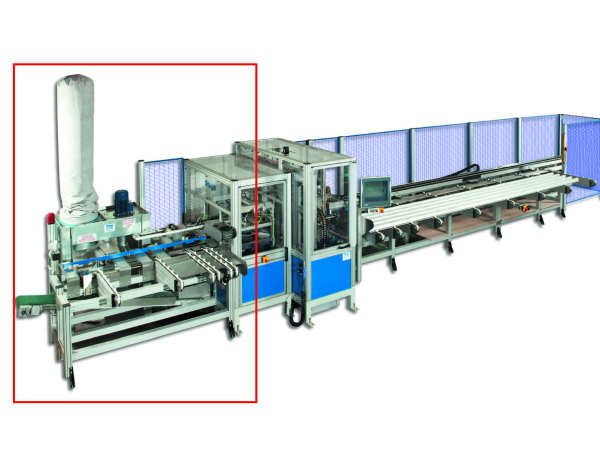

Procedures for Daily, Weekly and monthly maintenance on Autoflow Outfeed Table

Difficulté

Moyen

Durée

30 minute(s)

Introduction

The Machine has many moving parts, all which need regular maintenance. Below outlines what items need particular attention

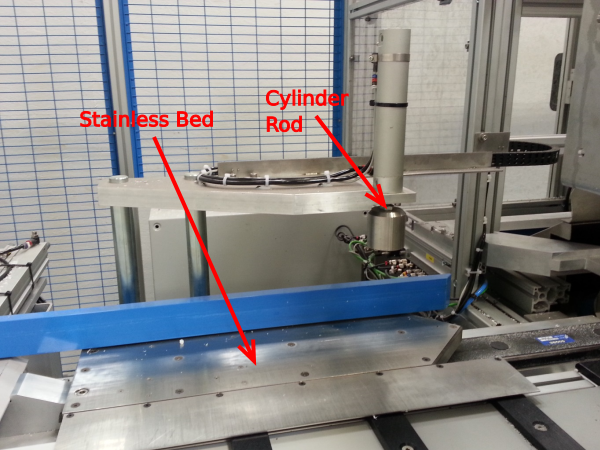

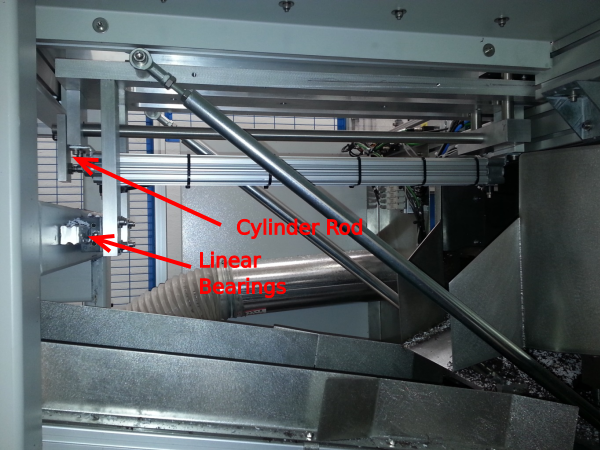

Étape 1 - Eject Bed

- Clean Stainless Steel Bed of swarf and remove any tape that may have transferred onto the bed during normal operation

- Lightly oil shaft on underside of bed, lightly oil cylinder rods

- Lghtly oil Hepco rail, 1 -2 pumps of grease into Linear Bearings

- Use a suitable foam cleaner for cleaning off the glue and tape residue left by the profile rolling along the beds

- Check Hepco rail, Linear Bearings, Shafts and cylinders for damage or wear

Étape 2 - Outfeed Pushers and Safety Gate

- Clean area of swarf and Debris

- Lightly oil Cylinder Rods, lightly oil Shafts

- Check function of gate and Siren via IO Screen

- Check Cylinder Rods and Shafts for wear or damage

- Check blue bar smooth function via IO screen

Étape 3 - Conveyor Belt

- Clean area of swarf and offcuts, empty waste bin as needed

- Check belt for signs of wear or cuts in belt

Étape 4 - Extraction System

- Check swarf level and change the bag when full

- Tap / shake gently the exhaust felt bag to allow the build-up of swarf on the inside of the bag to fall into the clear bag below

- Visually check the exhaust felt bags for any signs of damage/holes

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português