Weekly and Monthly Maintenance Procedures for Autoflow Infeed Table

Introduction

The following preventative maintenance tasks should be carried out regularly on the machine. The frequency depends on the machine use, but as a guide:

2-3 Shifts Weekly

40 Hrs/Week Bi-Weekly

20 Hrs/Week MonthlyÉtape 1 - Stainless Steel Bed

Use a suitable foam cleaner for cleaning off the glue and tape residue left by the profile rolling along the beds

Étape 2 - Main display unit (Monitor)

Clean display with soft cloth to avoid dirt, etc. causing malfunction of the touch screen

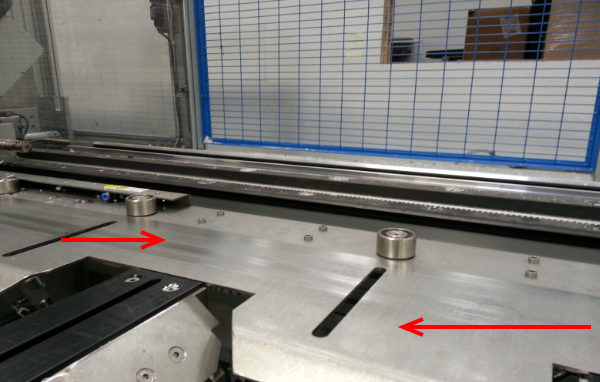

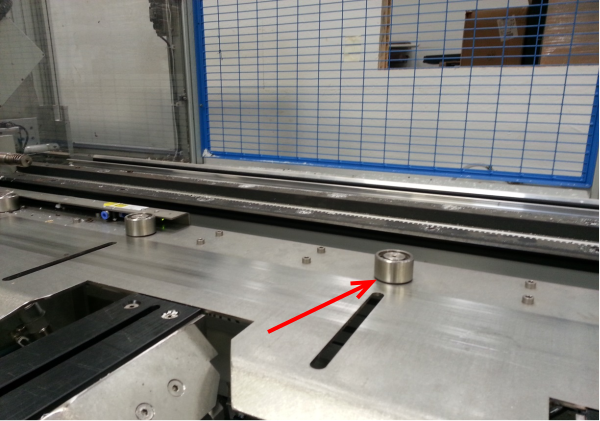

Étape 3 - Rear Backfence Rollers

Apply oil to top and side of roller units and then slowly spin them for a few revolutions to allow the oil to penetrate the bearings

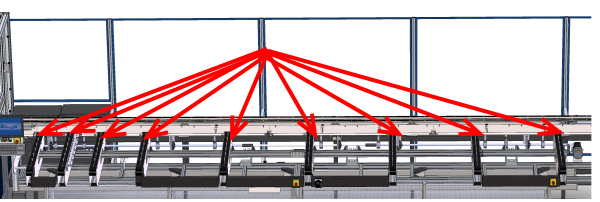

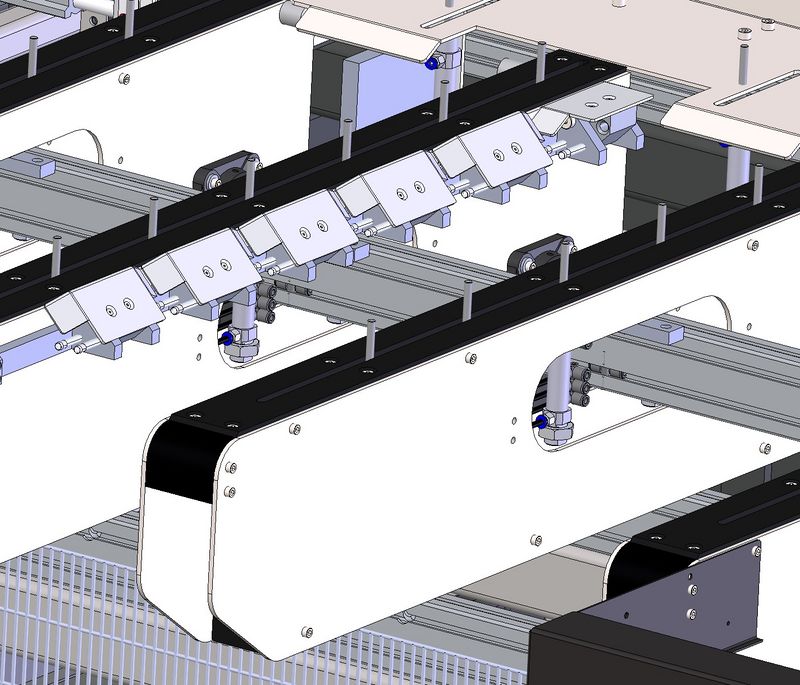

Étape 6 - Flapper Paddles

Check function and operaton of each paddle - ensure it does not stick in up or down position

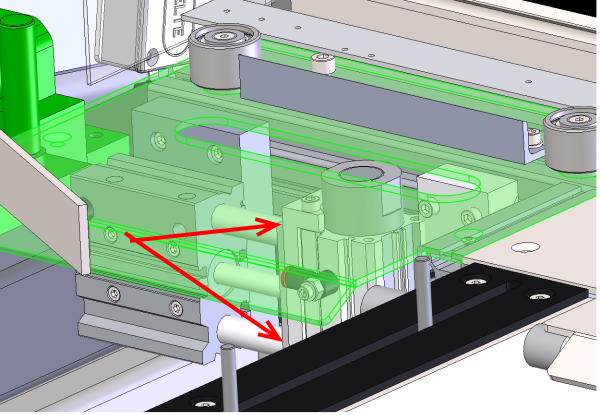

Étape 7 - End Stop

Ensure the end stop slides on the linear cylinder. The system acts under a low constant pressure and should slide easily

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português