Alignment and mounting procedure for main x axis drive rail

Sommaire

- 1 Introduction

- 2 Étape 1 - Mount Levelling jigs to blue section

- 3 Étape 2 - Level jigs

- 4 Étape 3 - Align Jigs

- 5 Étape 4 - Position Hepco rail

- 6 Étape 5 - Assemble carriage plate and fit to hepco rail

- 7 Étape 6 - Checking Levels and adjusting

- 8 Étape 7 - Laser checks on straightness

- 9 Étape 8 - Mounting brackets

- 10 Étape 9 - Remove set up jigs

- 11 Commentaires

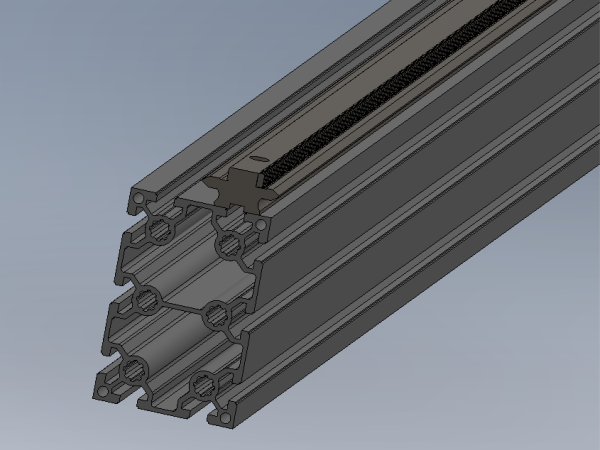

Introduction

Alignment and check procedure for mounting of hepco rail To main frame

Parts required

B0001102 hepco rail

D0015492 5 off vertical adjustment plate

D0015493 5 off Lateral adjustment plate

D0015072 1 off Carriage Plate

B0000184 journal wiper 4 off

B0000185 journal 2 off

B0000186 journal 2off

Hepco Levelling Jig

Hepco rail v block jigs

Hepco rail Drive rack pitching jigÉtape 1 - Mount Levelling jigs to blue section

Locations of jigs required

mounting method

Étape 2 - Level jigs

Levelling jigs

1st level jigs individually

2nd level jigs to each other

Étape 3 - Align Jigs

Use wire to align jigs to each other

Double checks ensure levels are correct after wire alignment

Q/C

Étape 4 - Position Hepco rail

Orientation

Measurement from end of frame

Correct joining procedure for hepco. V blocks tooth pitching

Q/c when hepco assembled and sat on jigs

Étape 5 - Assemble carriage plate and fit to hepco rail

Correct orientation of journals in relation to rack

Correct setting of journals a multiple points on rack (dokit required for journal setting)

Fit journal wipers

Étape 6 - Checking Levels and adjusting

Quality check of hepco beam on set up jigs

Use carriage plate to check Y axis and X axis levels

Adjustment of axis if not correct

Étape 7 - Laser checks on straightness

Use laser to check straightness of hepco beam on the Y and Z axis

Étape 8 - Mounting brackets

Fitment of mounting brackets to secure hepco beam to frame

Correct fasteners

Q/C check

Dowels?

Étape 9 - Remove set up jigs

Removal of setup jigs

Quality check once jigs removed

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português