Alignment process and criteria for module A aligning to module B

Sommaire

- 1 Introduction

- 2 Étape 1 - Position module A

- 3 Étape 2 - Level Y axis

- 4 Étape 3 - Level X Axis

- 5 Étape 4 - Roller bed quality check

- 6 Étape 5 - Adjust height of module A

- 7 Étape 6 - backfence alignment check

- 8 Étape 7 - Backfence Alignment setting

- 9 Étape 8 - Backfence alignment adjustment

- 10 Étape 9 - Finalise Height

- 11 Étape 10 - Quality check

- 12 Étape 11 - Fit Light Curtain

- 13 Étape 12 - Fit light curtain to buffer bar

- 14 Étape 13 - Fit light curtain to Module B

- 15 Étape 14 - Connect main air Feed

- 16 Commentaires

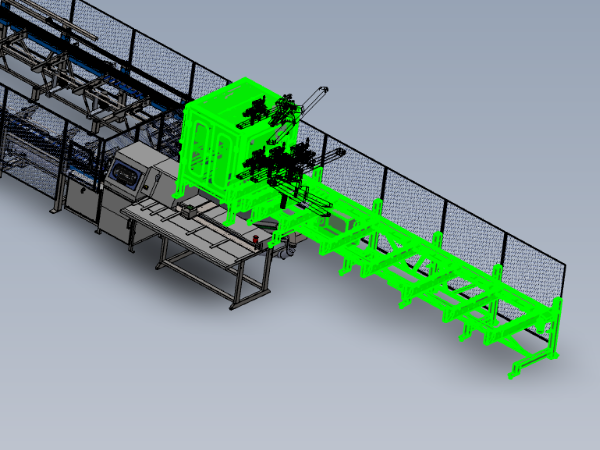

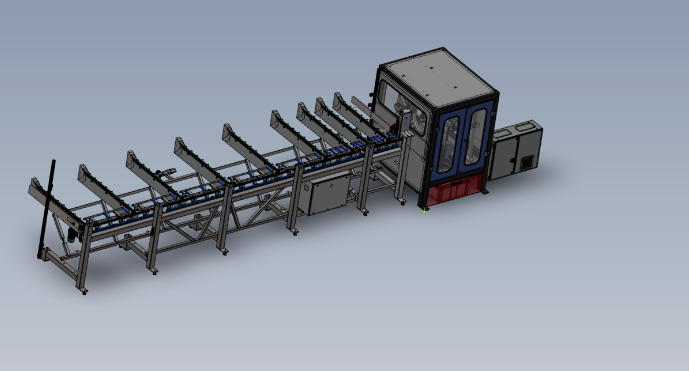

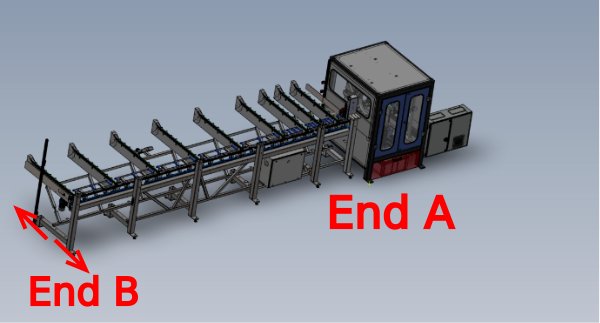

Introduction

Details and steps for correct alignment of Module A to Module B

Tools Required

Laser Level

300mm rule

1 meter yellow level

24mm spanner

Permanent marker

Pipe cutters

Ring main connection equipmentÉtape 1 - Position module A

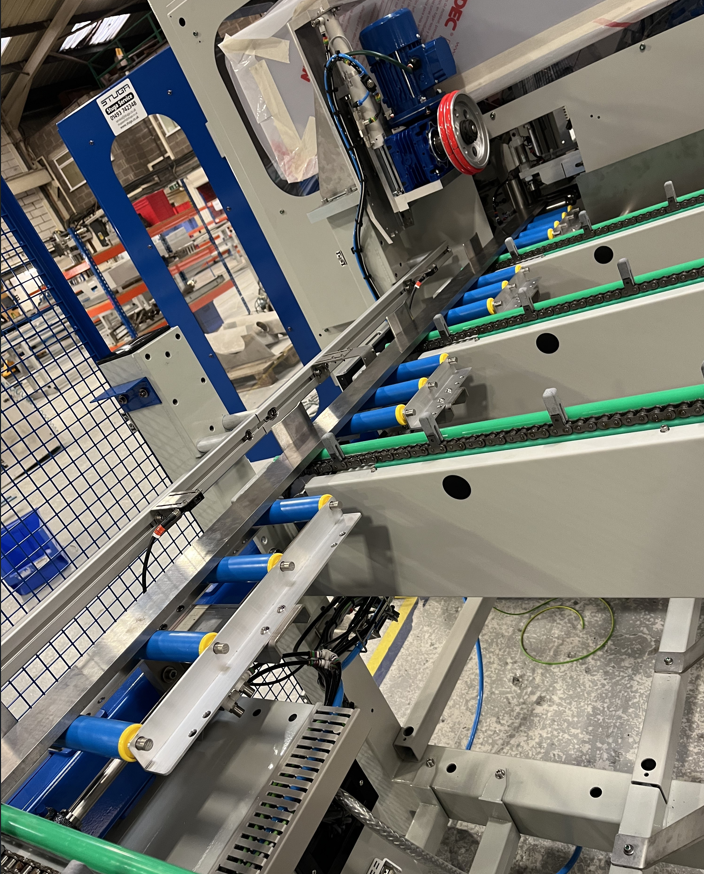

Position module A in front of module B

Use Infeed back fence to Multi head datum rollers as initial alignment guide for Y axis

Set gap of 23mm -+ 2mm between module A roller frame and module B roller block

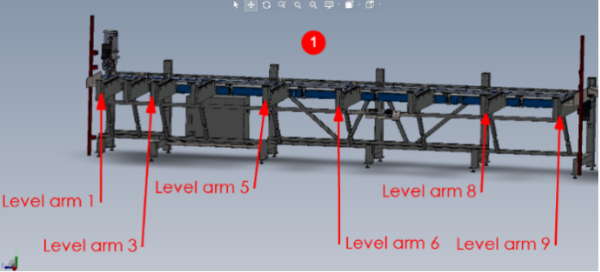

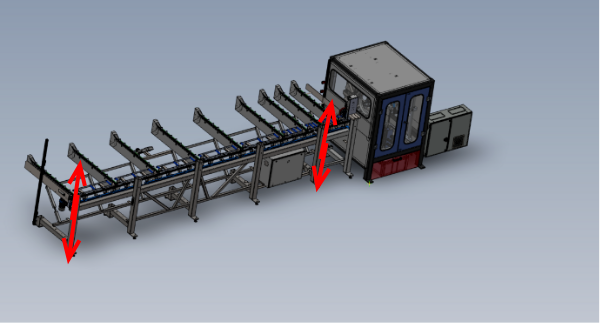

Étape 2 - Level Y axis

1 Use green strip on indicated loader arms and yellow 1 meter level to read level of arms indicated

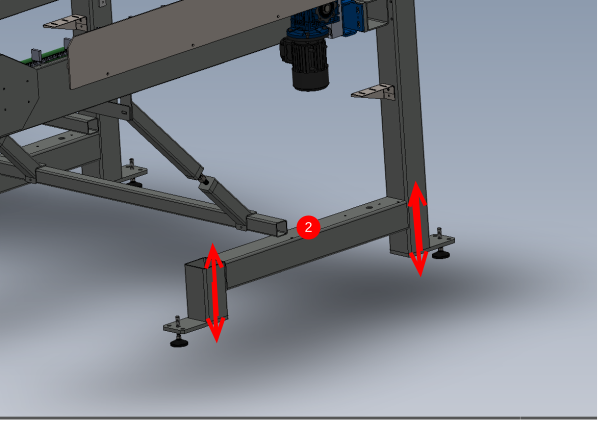

2 Adjust level of arms using jacking points below.

Recheck all levels on arms are correct once final arm has been adjusted

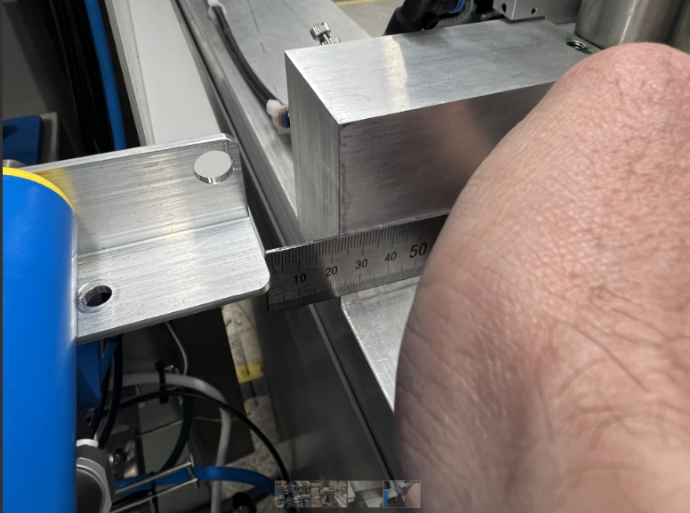

Étape 3 - Level X Axis

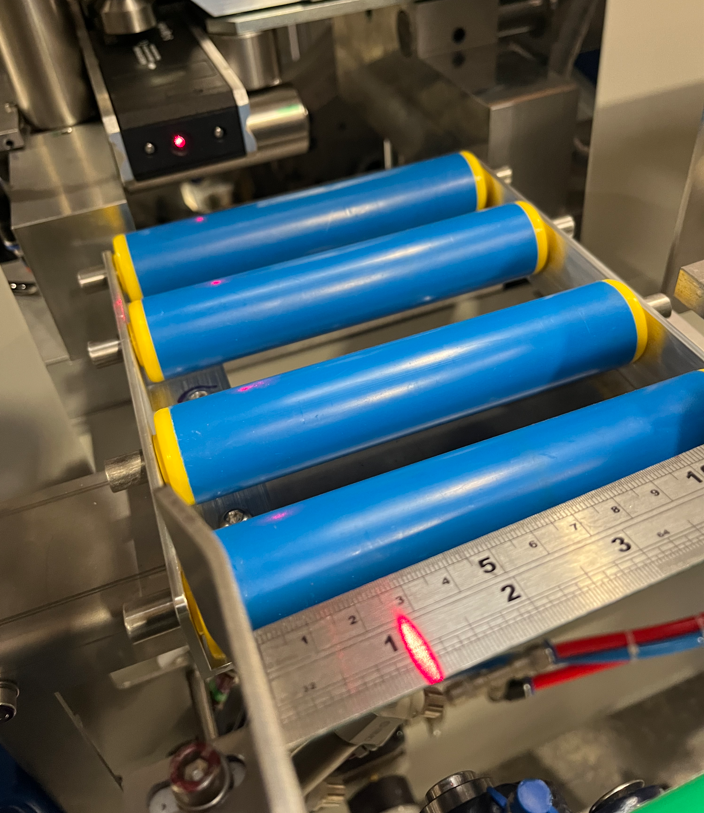

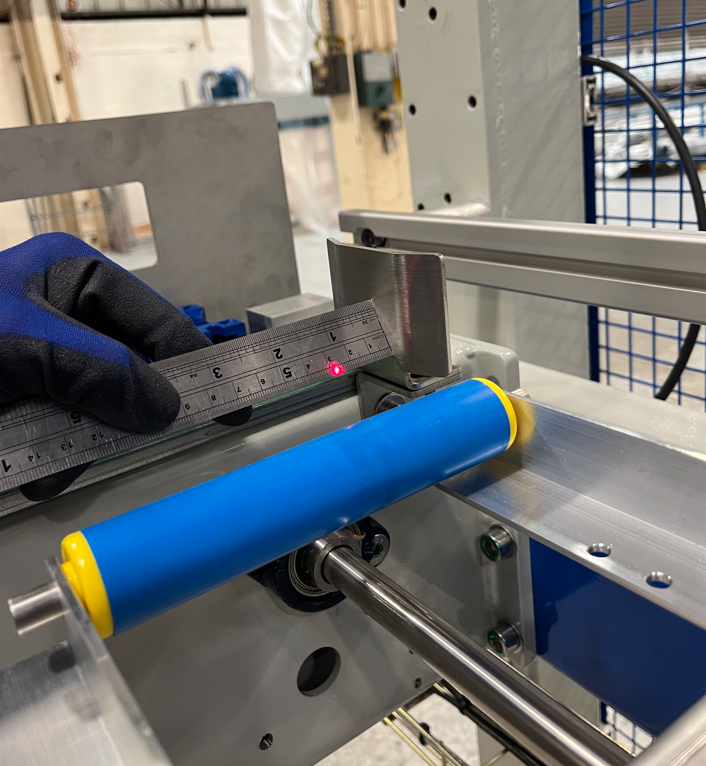

1 Use Module B horizontal datum rollers to position laser level on

2 Cast Beam from laser along infeed frame approximately 30mm away from back fence

3 Take measurement on level arm 1 at the indicated point from green runner strip to laser line

4 Measure and adjust level arm 9 to set to same as the first measured arm

Ensure adjustment points are altered in pairs with exact turns to ensure Y axis level is not lost

5 Repeat process at arms 3,5,6 and 8 repeating the same measurement as taken at arm 1

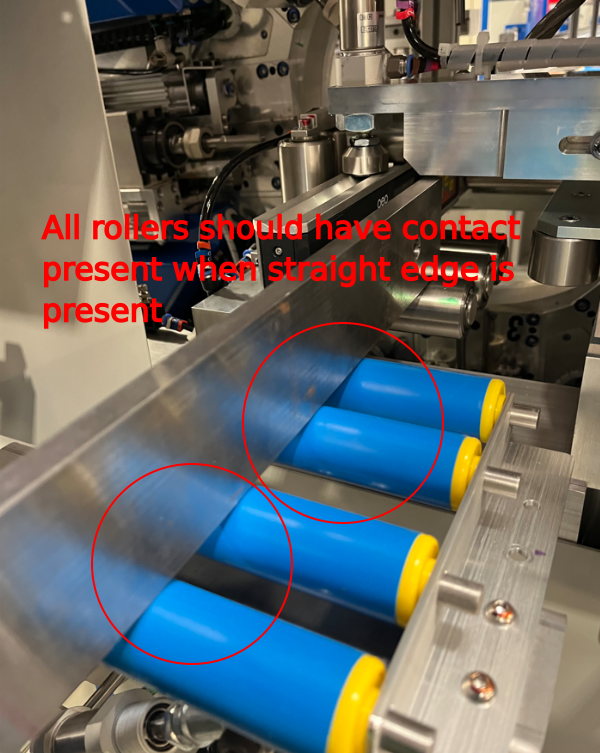

Étape 4 - Roller bed quality check

Use 2 meter straight edge to confirm alignment of roller beds once levelled

Move straight edge over roller assemblies to confirm there is no bump onto neighbouring rollers and all rollers are flat to straight edge

Report any discrepancies to supervisor for suggested remedial action

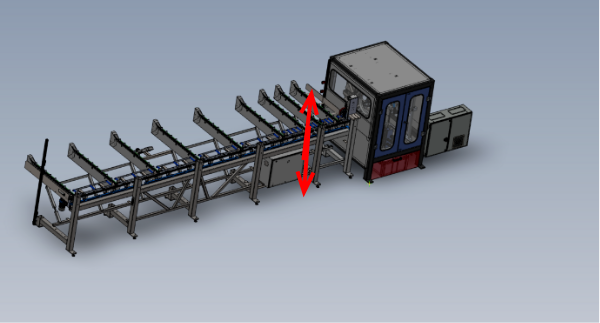

Étape 5 - Adjust height of module A

Module A height must now be adjusted to match the height of Module B datum rollers

Ensure the adjustment points are always turned the EXACT same rotation when adjusting. This will ensure that Y axis level is not compromised

Adjust height to match height of Module B datum rollers. Tolerance -+1mm

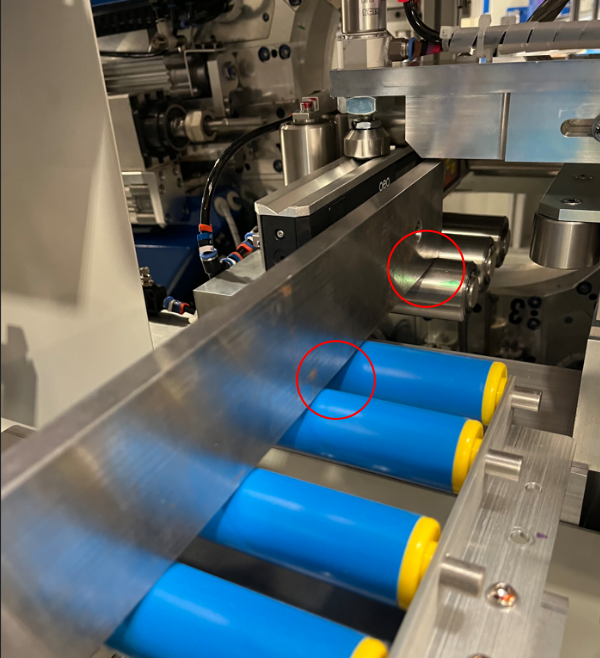

Étape 6 - backfence alignment check

Use a 2 meter straight edge to check that first 4 stainless back fences are correctly aligned to straight edge.

Contact should be as shown

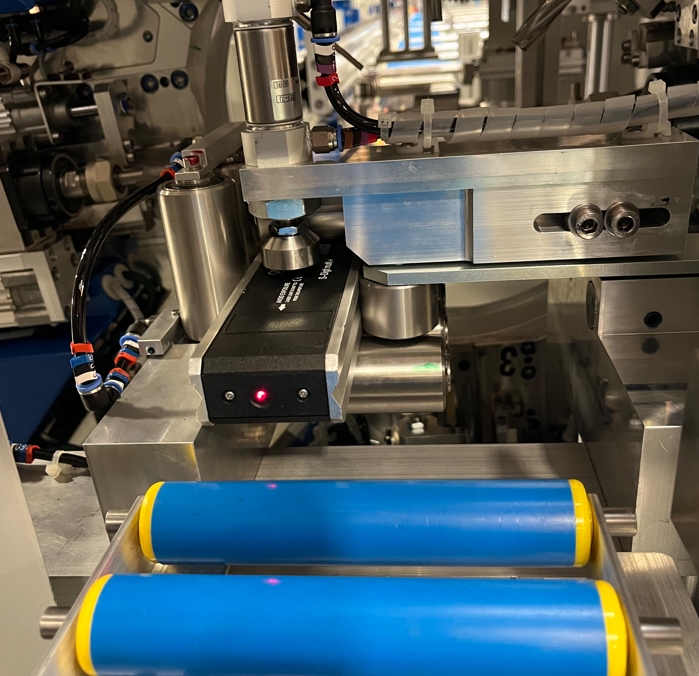

Étape 7 - Backfence Alignment setting

A laser must be used to ensure the backfence of the infeed is aligned along its entire length

1 Place laser against vertical rollers in module B, casting line over infeed table.

2 Take measurement of laser beam to first backfence closest to Module B

3 Take same measurement at furthest backfence , this will identify the misalignment if present as both figures need to be the same

Étape 8 - Backfence alignment adjustment

To adjust the measurement, the end B of the infeed frame must be moved in the direction required to correct the measurement

Keep adjusting End A and B until the following are correct

Laser measurement is less than 2mm in difference from End A to B

Backfence alignment at End A is 1mm (tolerance -+0.5mm) behind the module datum rollers

Étape 9 - Finalise Height

Height difference between module B datum rollers and infeed rollers should now be finalised

Adjust to set infeed roller 0.5mm - 1mm below Module B Datum rollers . Use Jacking points on frame and ensure all points are rotated equally to ensure previous settings remain

Étape 10 - Quality check

Please now quality check all settings for accuracy and correct setting

1 Y axis levels all correct and within sight lines of level

2 X axis level all correct and no greater error

3 Backfence alignment . Infeed backfence is set to the correct distance behind Module B datum rollers

4 Roller height is set to 1mm (-+0.5mm) lower than module B datum rollers

Étape 11 - Fit Light Curtain

Now the modules have been aligned , Safety light curtain should be fitted from

R0015266B

Étape 14 - Connect main air Feed

12mm blue pipe trailing from infeed table should be connected to module B air service unit

Leave pipe over length to allow final fitment during on site installation

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português