Weekly and Monthly Maintenance Procedures for Autoflow Gripper

Difficulté

Facile

Durée

30 minute(s)

Introduction

The following preventative maintenance tasks should be carried out regularly on the machine. The frequency depends on the machine use, but as a guide:

2-3 Shifts Weekly

40 Hrs/Week Bi-Weekly

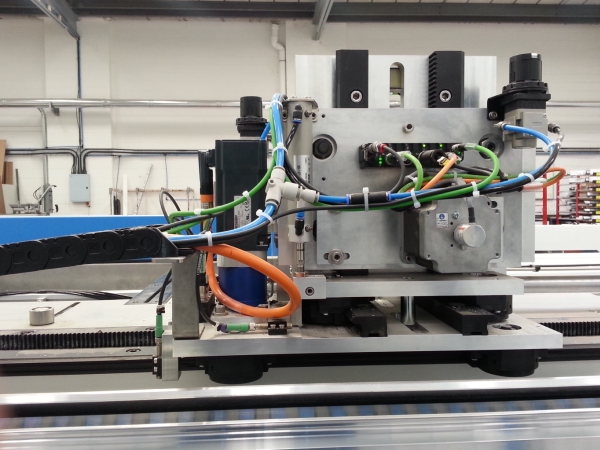

20 Hrs/Week MonthlyÉtape 1 - Linear Slide Rails

Wipe away any excess oil, dirt or swarf. Apply oil lubricant and wipe of excess

- Main X axis slideways

- GY Gripper Y axis Slideway

- GZ Gripper Z axis slideway

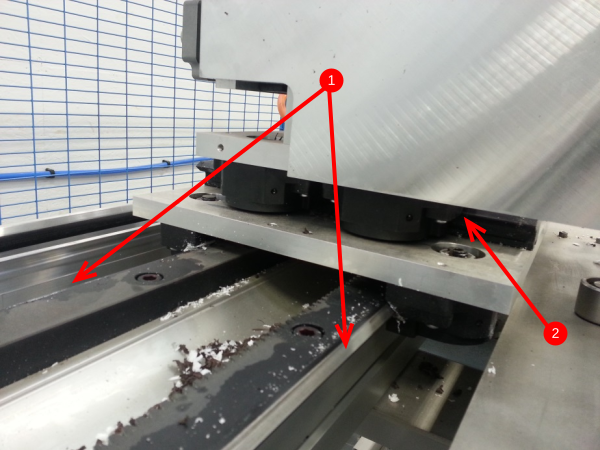

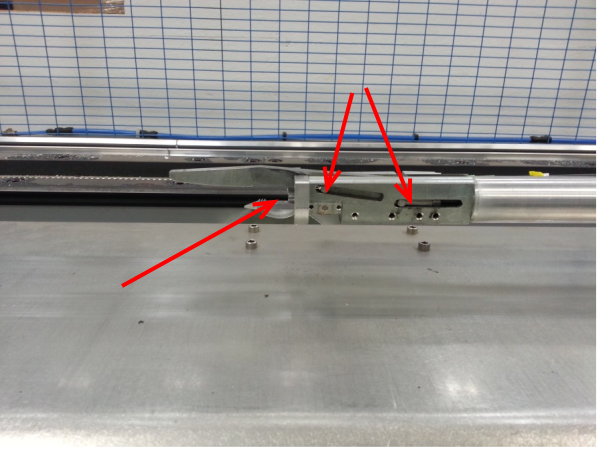

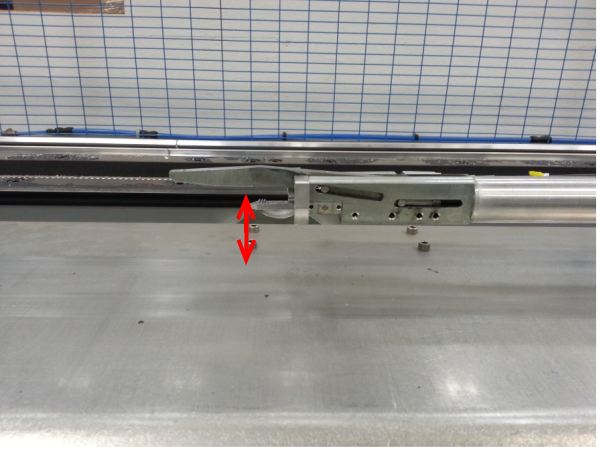

Étape 2 - Gripper finger

- clean away any swarf or excess oil from the mechanism; inspect gripper finger teeth for damage, wear or play

- visually check gripper finger teeth and shear pin for damage / wear

- clean away any excess swarf or oil, lightly oil pins for the movement mechanism with supplied oil

- Activate the gripper from the Service screen, ensure the gripper closes securely to 0.5mm-1mm

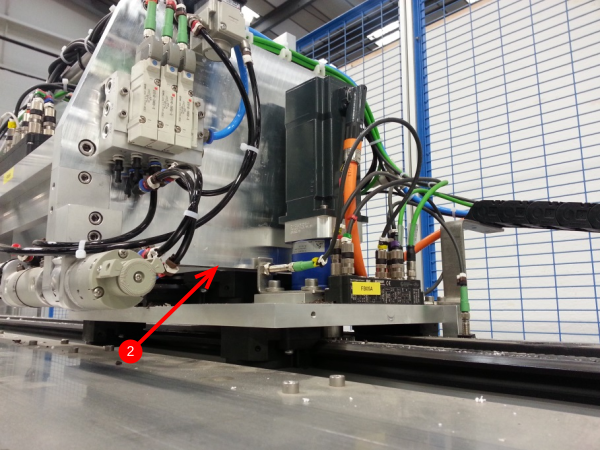

Étape 3 - Pinion Wheel and Rack

- Clean area of swarf

- visually check rack and pinion wheel for any damage, chips or cracks, remove any debris that may have become caught up in the teeth

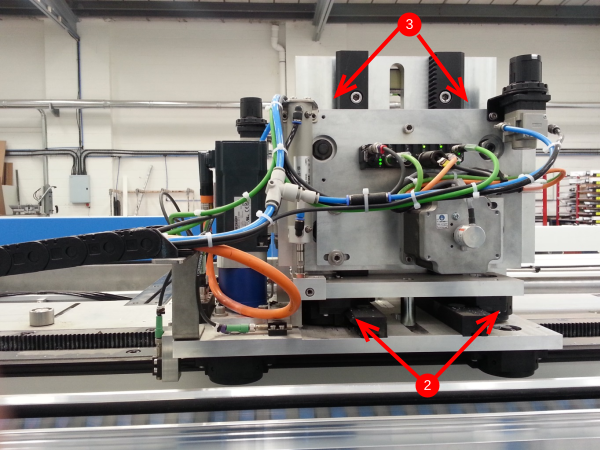

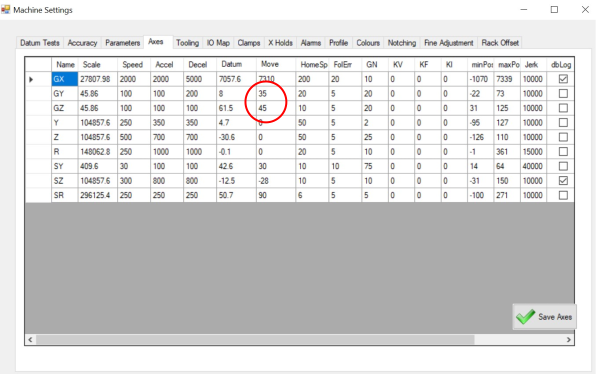

Étape 4 - Check Gripper Datum Position

The gripper GY and GZ position can become misaligned if there has been an impact with a stray offcut.

- Datum the machine

- Check the height of the centreline of the gripper teeth is within a millimetre of the GZ "Move" position in the parameter settings

- Check the same on GY

If these positions are very different, the gripper may not align with the openings on the profile. The gripper can be gently but firmly manhandled back into its correct position

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português