Using the netedit program to change the IP address of an ACEpc running DOS software

Introduction

The ACEpcs use two different systems for connecting a network

- NETBeui - this was used on earlier machines but reliability depends on the customer network setup. Reconfiguration after initial setup is difficult

- IP addressing - A setup system was written using IP addresses to connect. This is a little harder to set up, but is easier to change later. A special program called netedit was written which updates all the correct files in the background

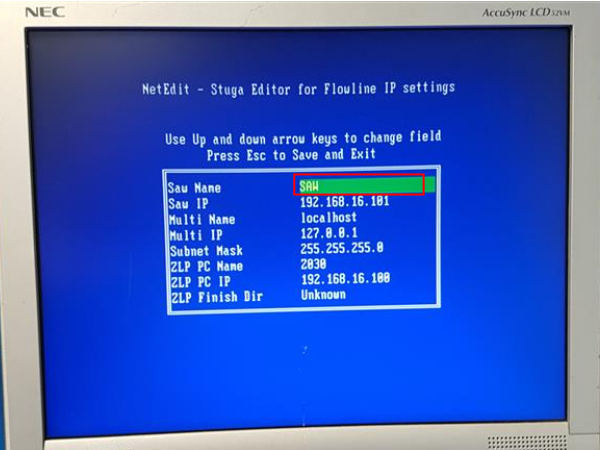

Étape 1 - Run NetEdit from command prompt

At DOS prompt, ensure you are on drive C: by typingc:

netedit

If the file does not exist, follow the procedure for installing the netedit software using a 'netsetgo' disk

https://stuga.dokit.app/wiki/ACEpc_Installing_netedit_with_NetSetGo_disk

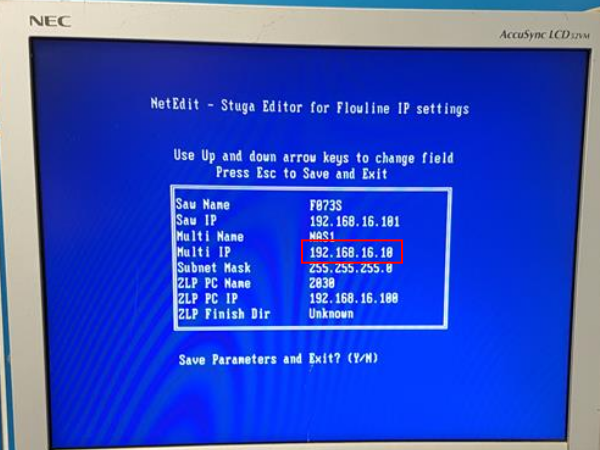

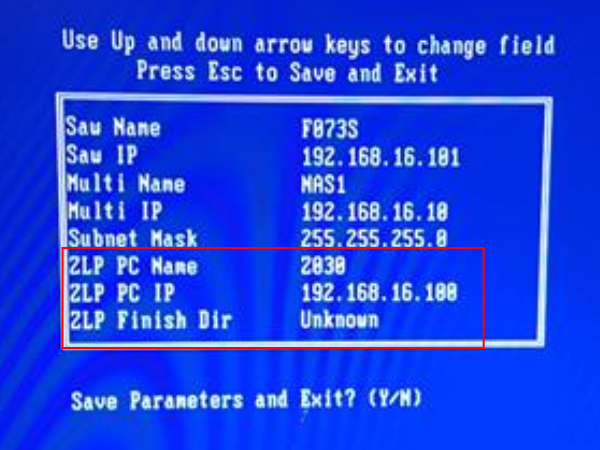

Étape 2 - Set the saw name

Build number must be unique. If a flowline saw put an "s" on the end. i.e. F073S

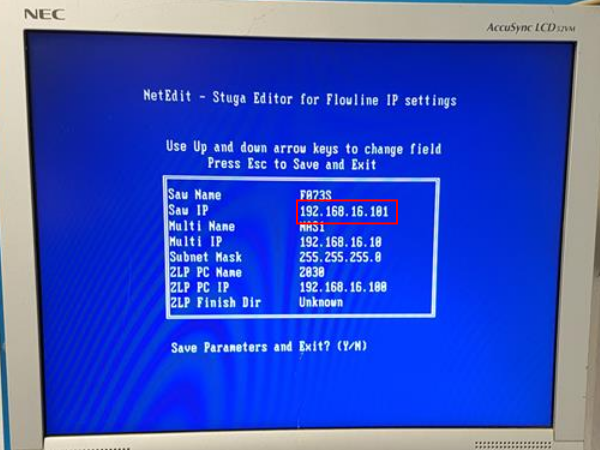

Étape 3 - Saw IP address

This is supplied by customer. IT department

If testing in house it needs to be on the 192.168.16.xxx range.

e.g 192.168.16.101

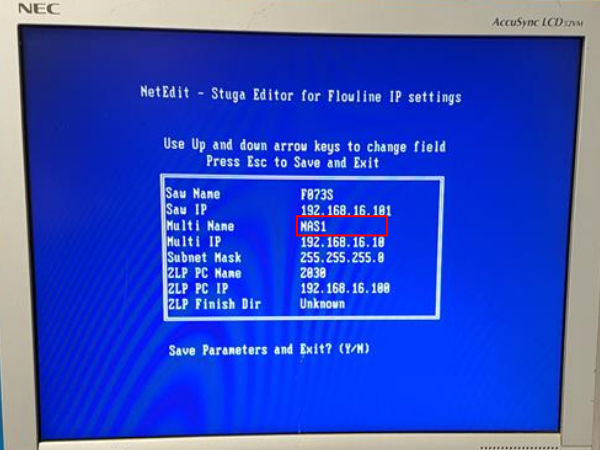

Étape 4 - Multi Name

If this is for a Flowline - Build Number of Flowline machining center

Otherwise this will be the net NETBEUI name of the pc you are connecting to.

For testing at stuga this will be NAS1

Étape 5 - Multi IP

If this is for a Flowline - IP Address of Flowline machining center

Otherwise this will be the IP address of the pc you are connecting to.

For testing at stuga this will be 192.168.16.6

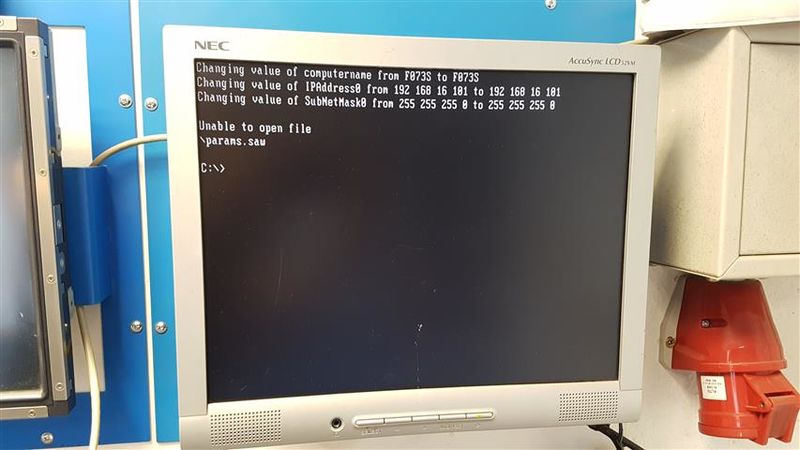

Étape 9 - Remove Disk and reboot

Ensure the floppy disk is removed and reboot

Success will be seen if the machine boots into Drive D:

If the saw is connected to a flowline, the saw software should run automatically

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português