This page will describe how to generate a Postest (operation position test), and is used to set the distance relationship between the routed holes and the saw blade so that routed pieces line up correctly back to back.

Postest

To Produce a Postest perform the steps below

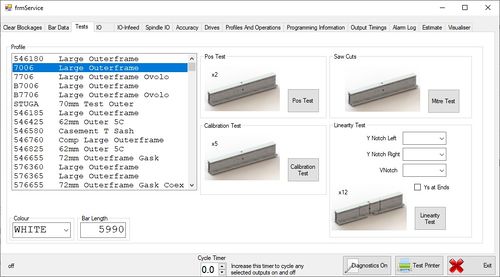

- Tap on the F7 Service button on the main toolbar

- This will open the service menu, click on the Tests tab. you will see the screen to the right.

- Select your profile from the list

- Select the colour from the Colour Drop Down

- If you are using an offcut, change the standard bar length to the length of the offcut you wish to use.

- Tap on the Pos Test Button

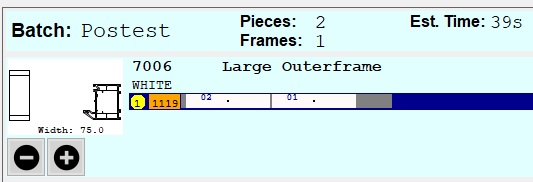

This will add 2off 450mm pieces with square ends and a datum test in the middle, to the bar queue as below

Bar Queue

Above is a depiction of the bar queue, prep and cut these pieces as normal.

Lining up the Pieces

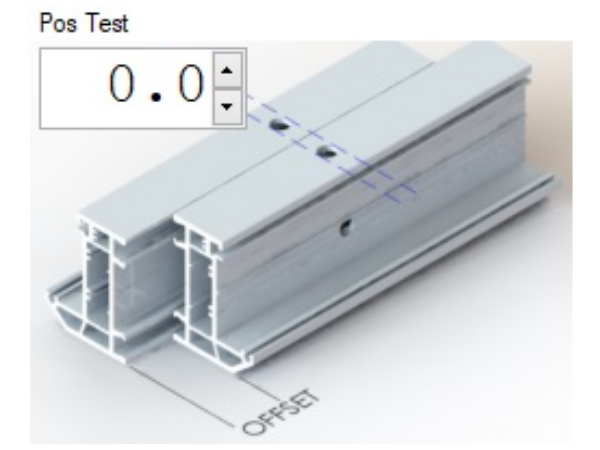

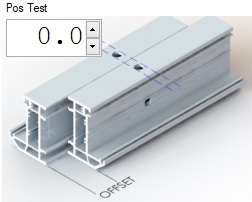

Once the postest pieces have been cut they should be put back-to-back as shown to the right. With the holes Lined up the Offset at the ends of the profile should be measured using accurate callipers. You need to be able to measure to an accuracy of 0.1mm.

If prepped on outer frame the bottom piece should have the beadrail toward the tester, and the top piece should have the beadrail away from the tester.

Pass:

If the test shows an error smaller than 1mm, the test is ok.

Fail:

If the error is greater than 1mm, this could affect the accuracy of production. Double check your measurements. Then RUN THE TEST AGAIN two more times preferably on different bar lengths.

If (and Only if) the error is exactly the same for all of the tests carried out, you can change the settings to alter the position of the holes in relation to the saw cuts.

- From here click into the Settings menu, on the right there will be 2 possibilities, determine which picture best reflects your pieces (either the top piece is to the left or to the right of the bottom piece)

- Enter the offset into the appropriate box. then click the Save button below.

- This will change the appropriate parameter related to your machine.

- Once complete, redo the postest to check that all is now well.

If the error seems to be random, there will be another root cause, and changing the parameters will NOT solve the issue, it will only make the situation worse.

There are many root causes to an accuracy problem. For a full accuracy guide for a competent engineer see General Accuracy Guidelines

To Return to the main page, please click WinMulti Software Operating Guide

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português