This page will describe how to perform a Datum Test

The Datum test tab should Ideally be used before production EVERY day. This area is used to ensure once the machine has been initialized that all the routing axes are in the correct place.

An operator should be able to run the datum test before production each day (or at the request of maintenance / Stuga staff) to satisfy themselves that the machine is cutting accurately.

Running the Datum Test

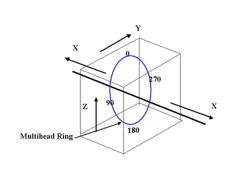

To use it correctly you need to understand the axes on the machine. The diagram to the right illustrates this.

To run a datum test:-

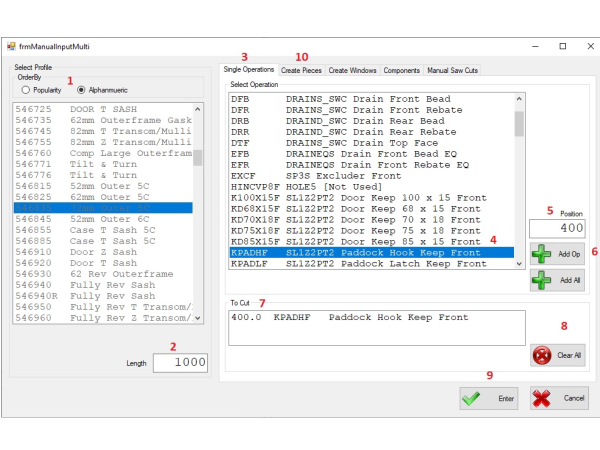

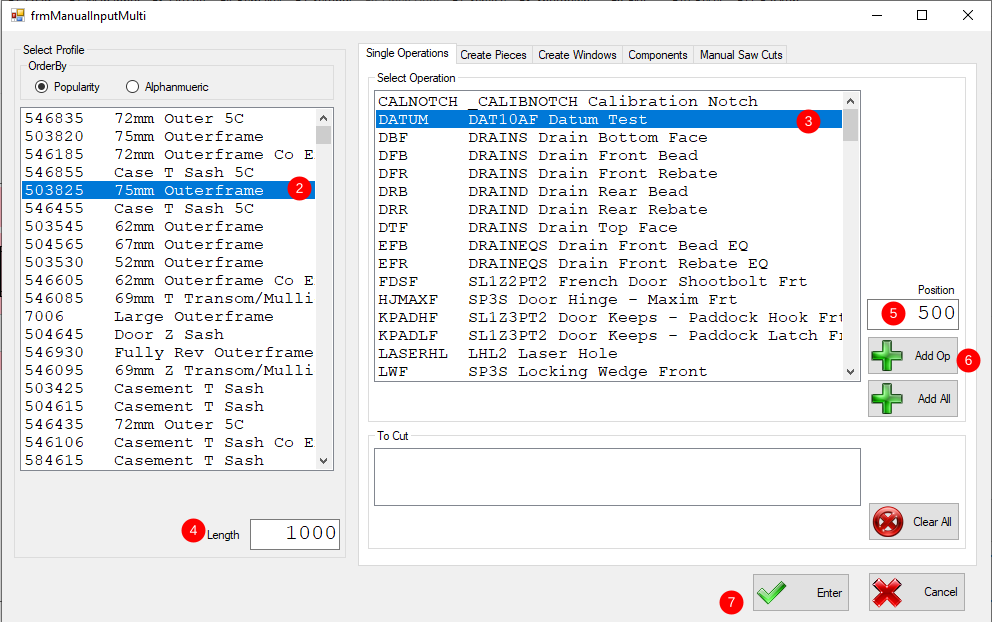

1. Tap the Manual Input Button from the main screen.

2. Select the profile from the list (preferably large outer)

3. Select the datum prep from the operations list

4. Type in the length of the profile into the Length field (ideally 1500mm+)

5. Type in the position of the datum prep into the position field (at least 400mm from either end of the bar.

6. Tap on the Add Op button

7. Tap on the Enter Button, this will create a batch on the main screen, which can be cut in the normal manner.

Once this has been cut and prepped you should have your test profile with 4 x 10mm holes prepped, one on each face of the profile.

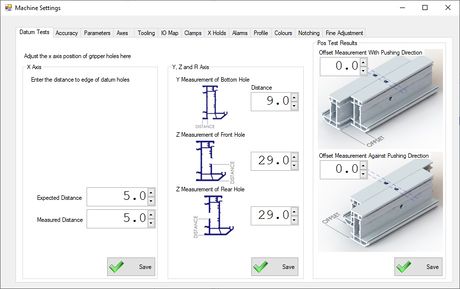

Adjusting the Datums

The holes produced should be measured carefully with accurate calipers and compared to the results in the Machine settings->Datum tests Tab. This can be accessed by clicking on the Settings button on the main menu.

The measurements are as follows

X Axis: Measure from the gripper end of the profile to the centre of the bottom 10mm hole. This should measure the same as the figure that was typed into step 5 above

Y,Z & R: See the on-screen diagram for measuring the position of the datum hole.

Compare the measurements to your values

If any of the datum positions are incorrect to the expected values in the boxes, double check your measurements. Then RUN THE TEST AGAIN two more times

If (and only if) you get a repeating result that differs from the values on the form, you can modify the numbers to match your results. After the datums have been modified tap on the appropriate "Save" button, Then Exit.

ALWAYS re run another test on the same piece in a different position, and ALWAYS Reinitialise the machine after each test by pressing the Reinitialise button. This forces the system to re-datum or re-home all the axes

If the datum position varies from test to test, then there is another root cause affecting the accuracy. See Common Issue - Datum Holes In Wrong position.

To Return to the main page, please click on WinMulti Software Operating Guide

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português