How to change the main saw blade on a Stuga machine

Sommaire

- 1 Introduction

- 2 Pièces et outils

- 3 Étape 1 - Stop Cutting

- 4 Étape 2 - Open the door

- 5 Étape 3 - Loosen Blade

- 6 Étape 4 - Remove Fastening

- 7 Étape 5 - Remove Blade

- 8 Étape 6 - Fit New Blade

- 9 Étape 7 - Refit Bolt, Plate and Washer

- 10 Étape 8 - Measure new blade thickness (Kerf)

- 11 Étape 9 - Update kerf Parameter

- 12 Étape 10 - Close the door

- 13 Étape 11 - Reset Estop

- 14 Commentaires

Introduction

Stuga recommends this blade be changed after 1-2 weeks of cutting - symptoms to determine if the blade needs changing:

- Awful cutting sound / smell

- Profile dragging (sizes too short)

- Brown burnt swarf

- Smoke coming out of profile end while cutting

- Pièces et outils

Pièces et outils

Étape 1 - Stop Cutting

Make sure you have stopped cutting and nothing on the machine is moving - press an emergency stop button to ensure this.

Étape 3 - Loosen Blade

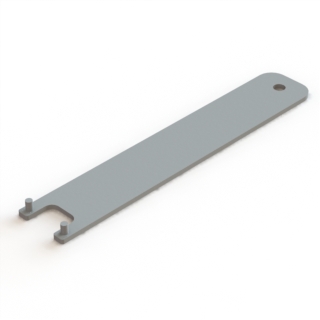

Using the saw blade 'C' spanner and the 24mm spanner, loosen and remove the main bolt going through the centre of the saw blade - anti-clockwise to loosen.

Étape 4 - Remove Fastening

Once the bolt is loose; remove the bolt, washer and plate.

Étape 5 - Remove Blade

Now carefully remove the blade, with this blade being 500mm it will be tight. Ensure you take note of which way the blade spins.

Étape 6 - Fit New Blade

Fit the new blade ensuring the teeth are facing the same way it was removed

Étape 7 - Refit Bolt, Plate and Washer

Now fit the plate, washer and bolt ensuring it's tight

Étape 8 - Measure new blade thickness (Kerf)

Measure the thickness of the brand new or sharpened blade - this should be between 3.8mm - 4.1mm

Étape 9 - Update kerf Parameter

Through the winSaw software go into '[F5] Settings' and update the 'Kerf' parameter to what the blade thickness is.

Press 'Save'.

Étape 10 - Close the door

Press '[F10] Reset Saw', now close the main door and ensure it will not open and that the 'Guard' message clears

Étape 11 - Reset Estop

Reset the emergency stop circuit by unlatching emergency stop buttons and pressing the physical blue 'ES RESET' button

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português