Fitting the crank upgrade to Z065, Z066, Z067

Sommaire

- 1 Introduction

- 2 Étape 1 -

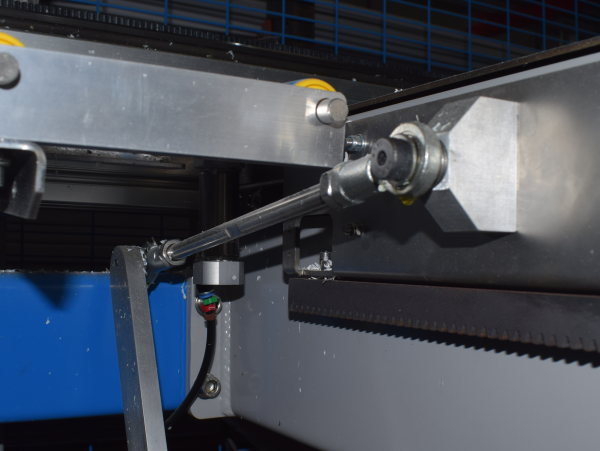

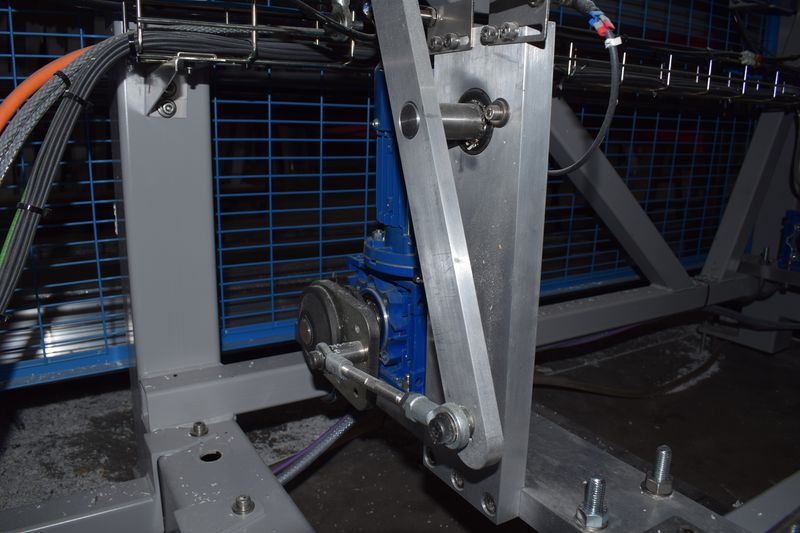

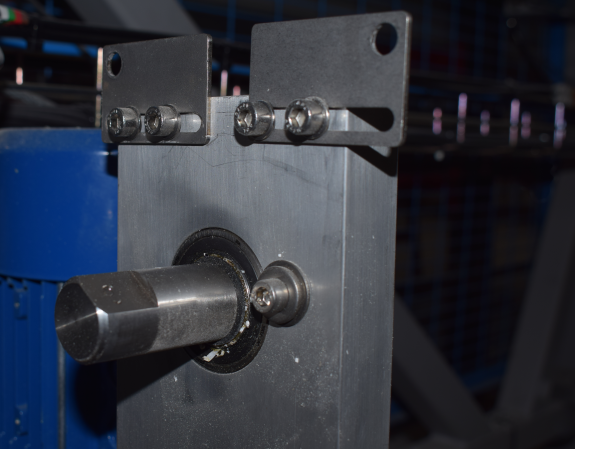

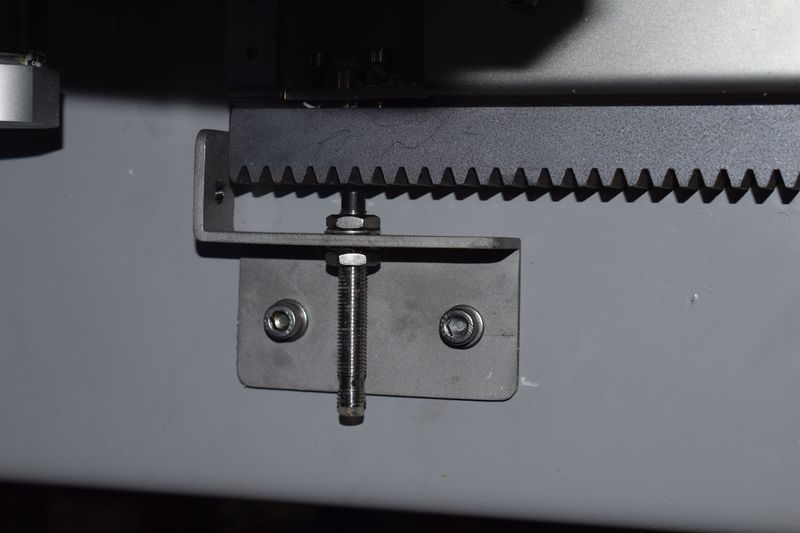

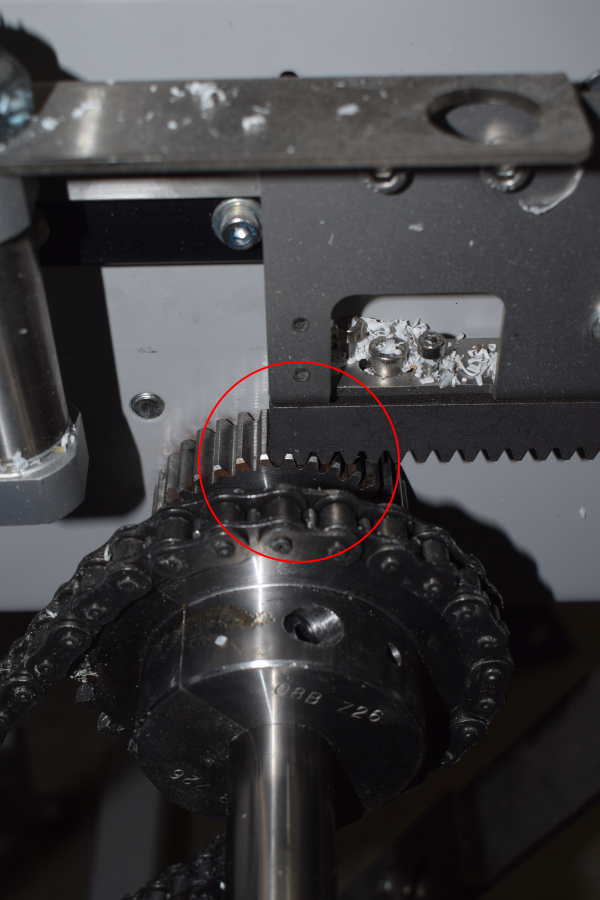

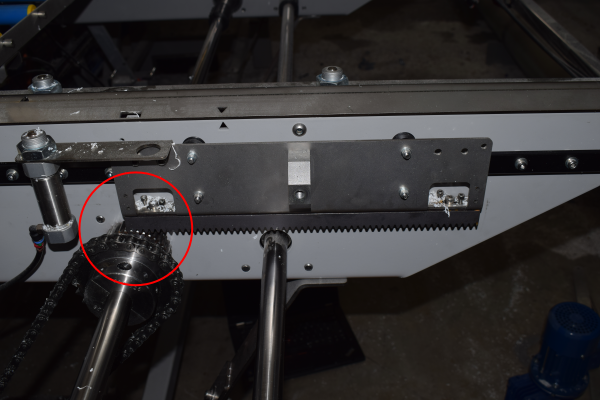

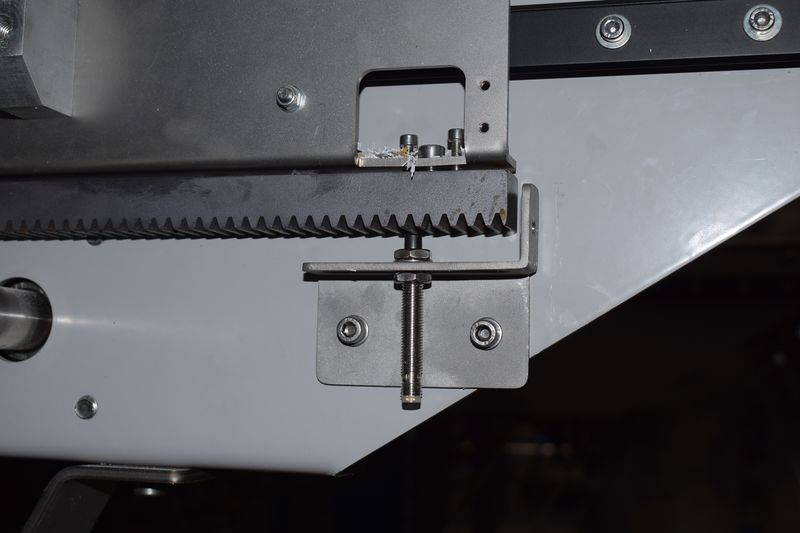

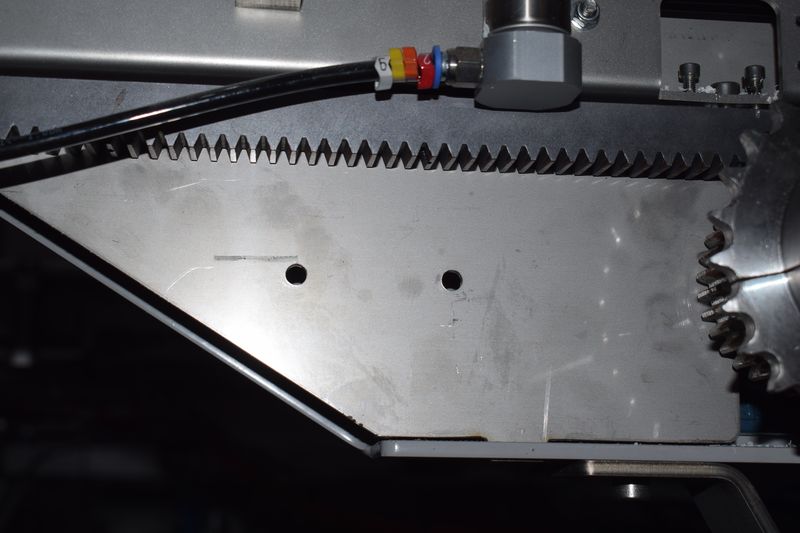

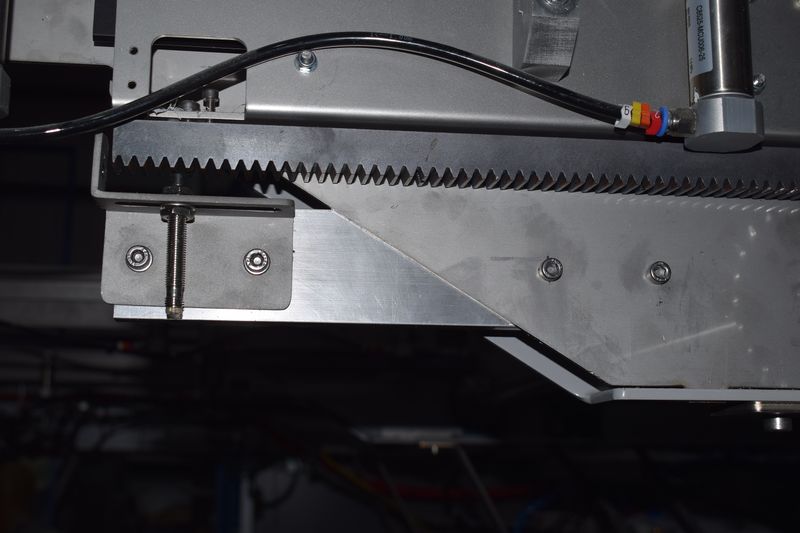

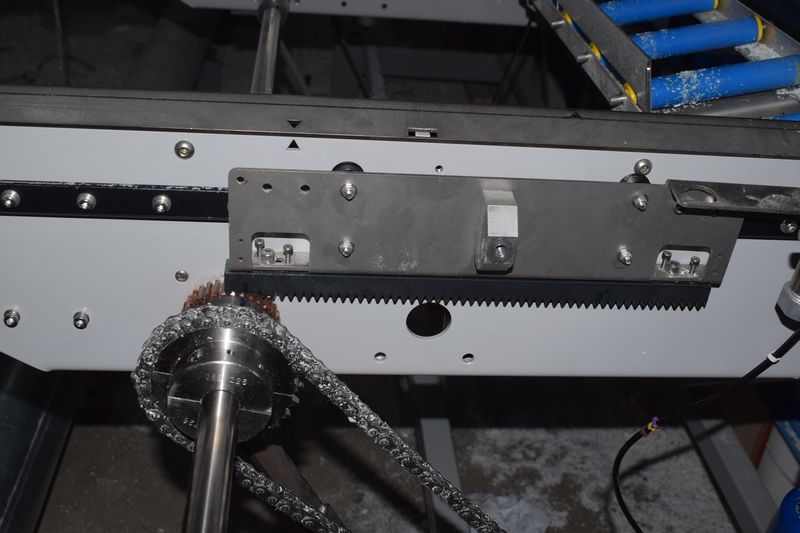

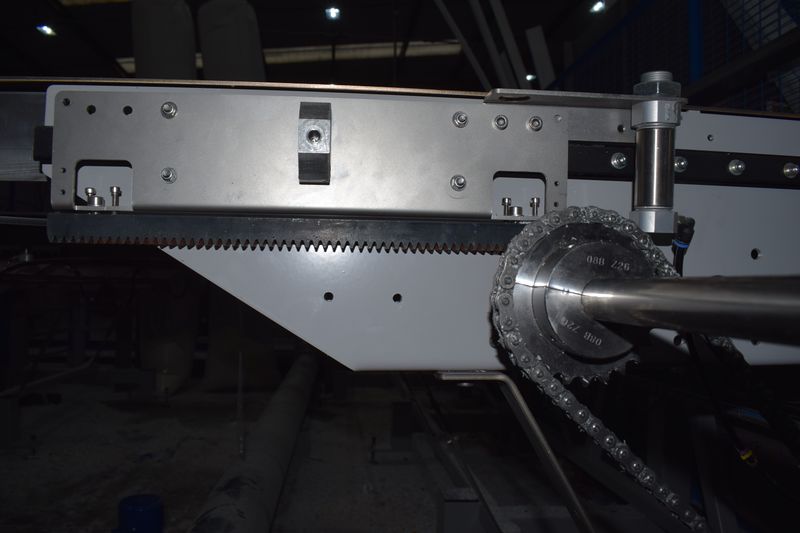

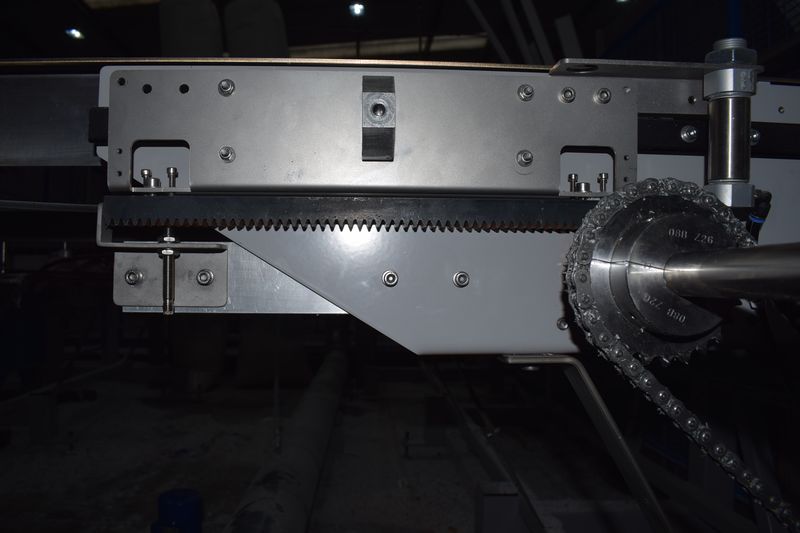

- 3 Étape 2 - Remove Link arm connecting to rack and pinion

- 4 Étape 3 - Remove pivot shaft and arm

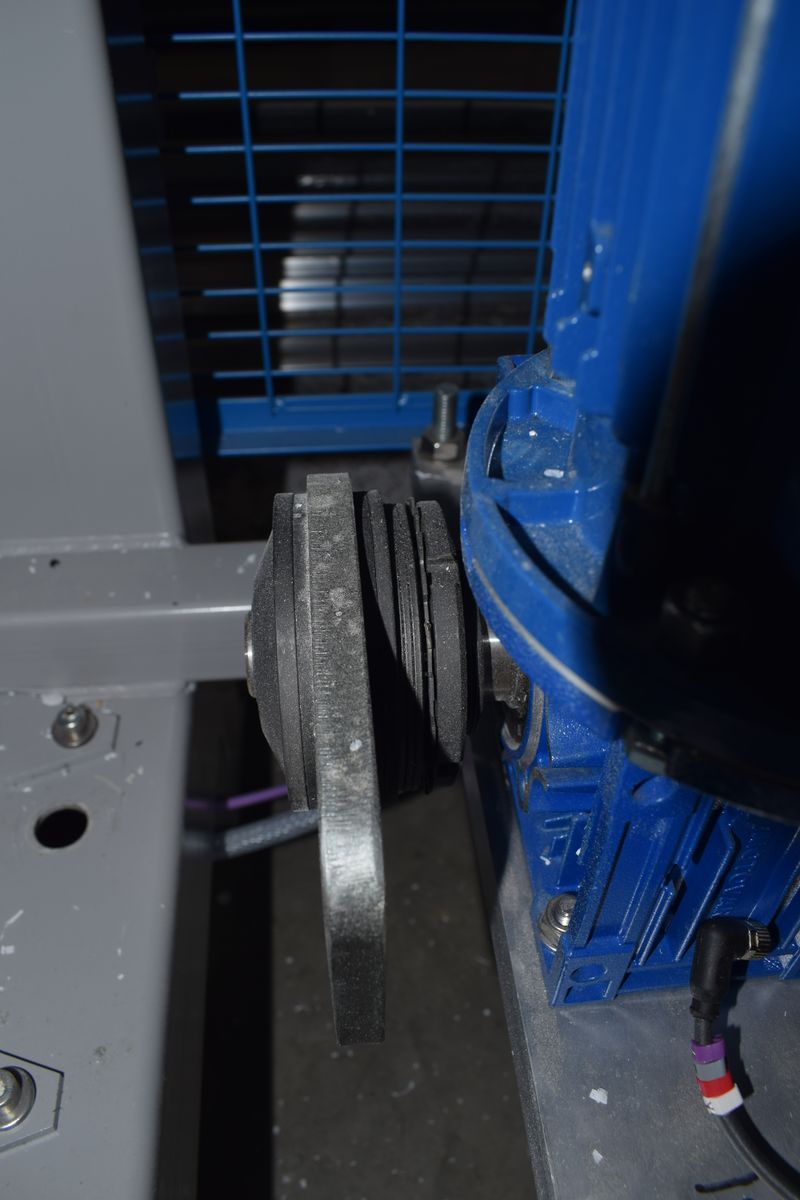

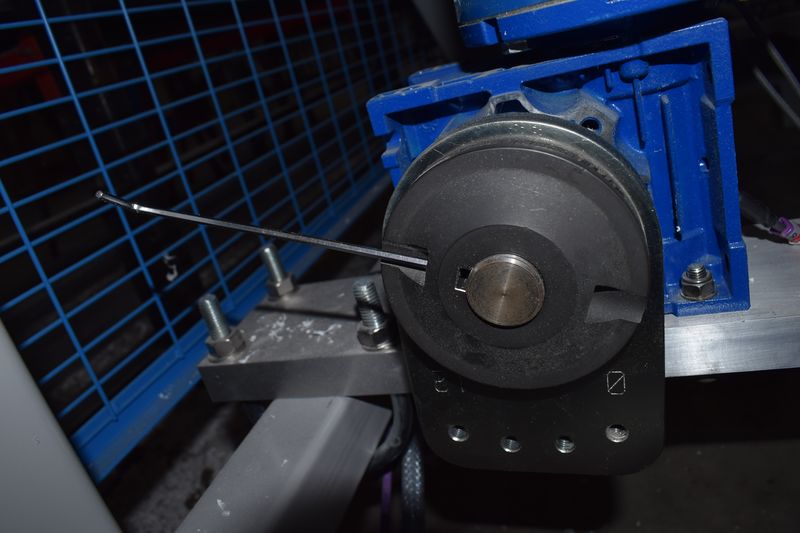

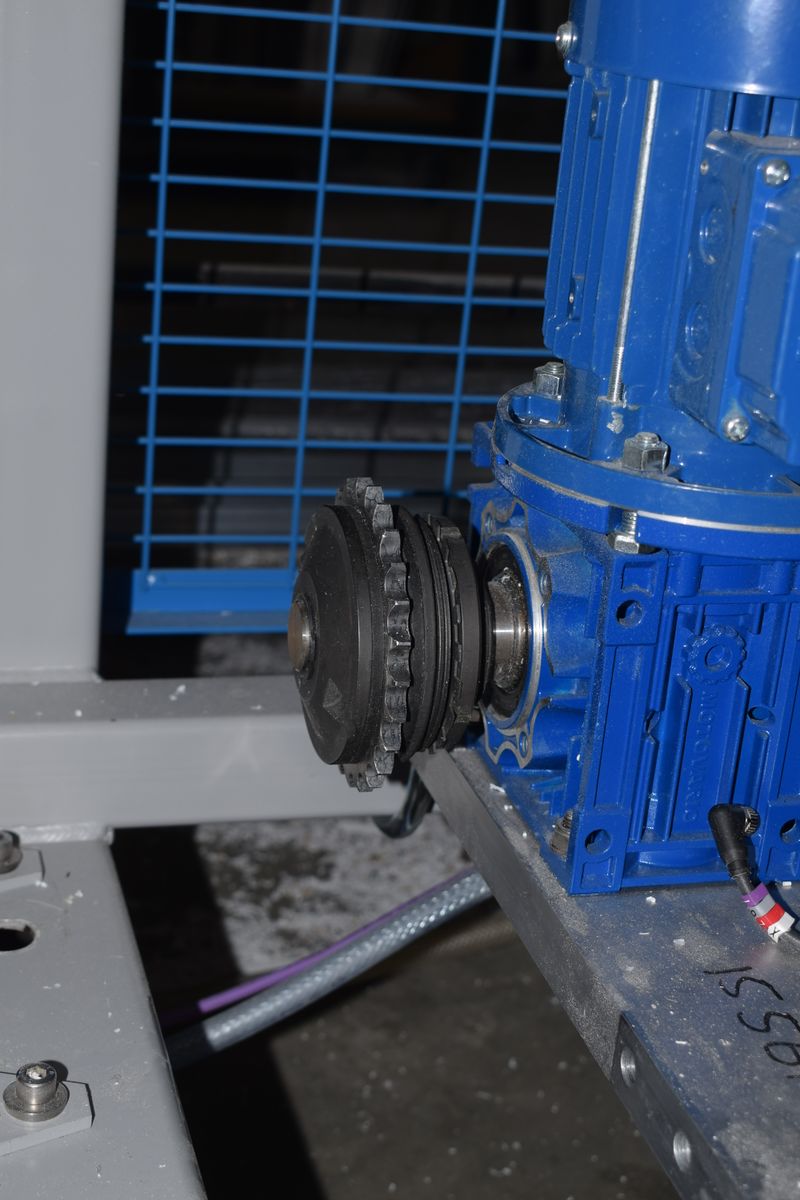

- 5 Étape 4 - Undo clutch and remove Cam

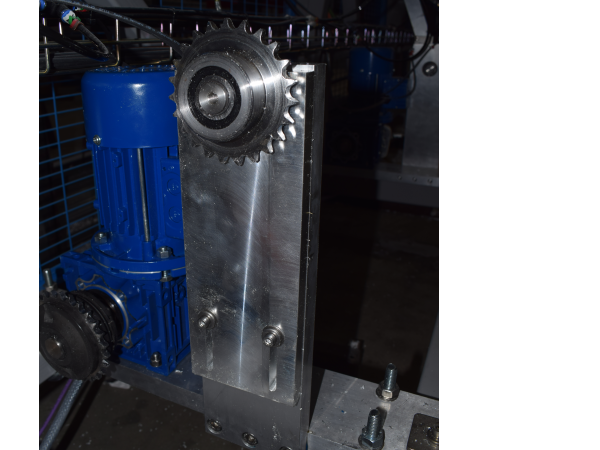

- 6 Étape 5 - Add sprocket to clutch

- 7 Étape 6 - Fix idler plate to upright

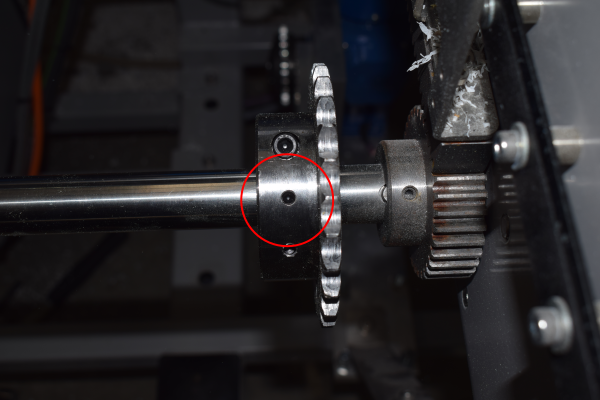

- 8 Étape 7 - Fix split sprocket onto drive shaft

- 9 Étape 8 - Drill and pin split sprocket to shaft

- 10 Étape 9 - Add chain minimum length sprocket to sprocket

- 11 Étape 10 - Fit Module C Crank Home sensor plate to Arm 5

- 12 Étape 11 - Fit Module C Crank Out sensor plate to Arm 5

- 13 Étape 12 - Fit Module D Crank Home sensor plate to Arm 5

- 14 Étape 13 - Fit Module D Crank Out sensor plate to Arm 5

- 15 Étape 14 - Fit Module E Crank Out sensor plate to Arm 5

- 16 Étape 15 - Fit Module E Crank Home sensor plate to Arm 5

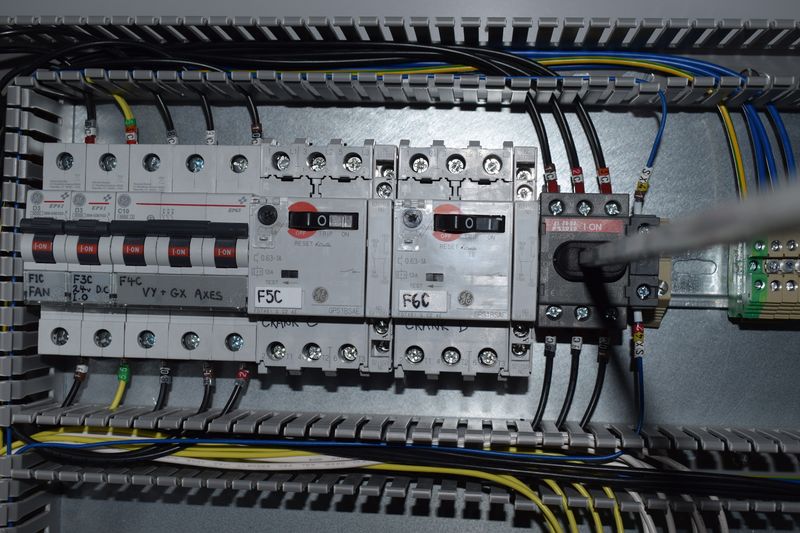

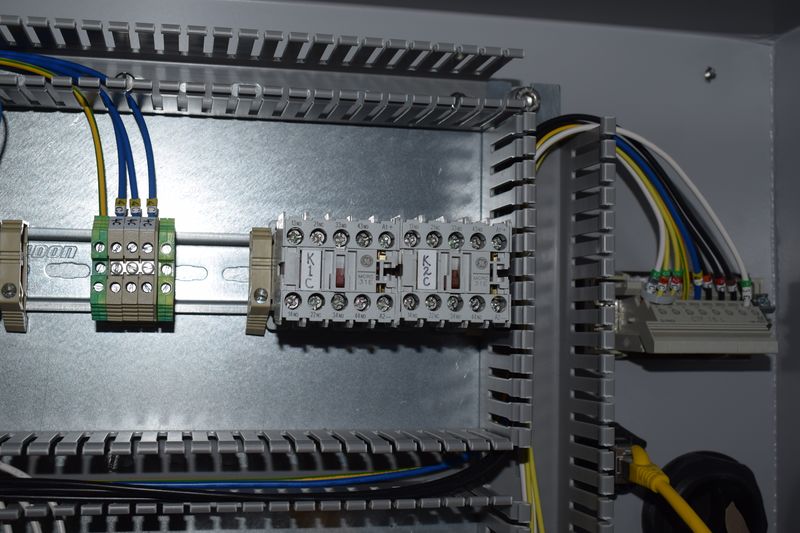

- 17 Étape 16 - Remove 2 off motor breakers and contactors from Module C

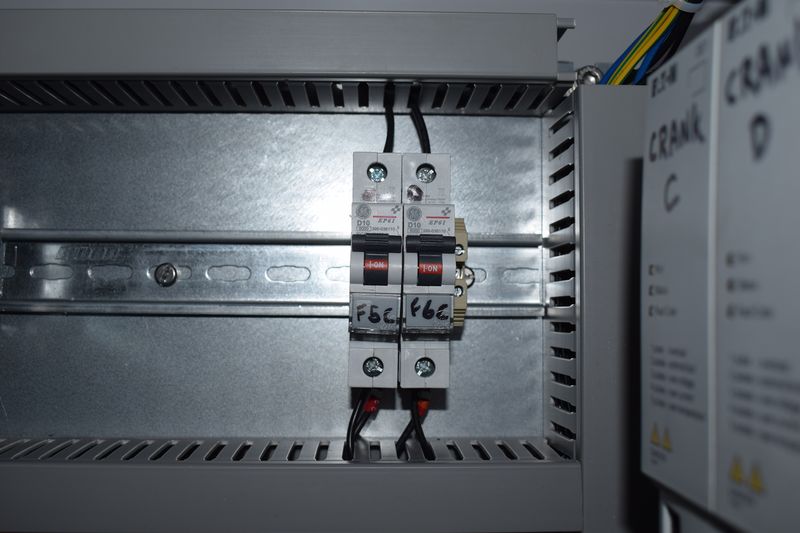

- 18 Étape 17 - Add 2 off 10A single pole MCB's in Module C

- 19 Étape 18 - Add 2 off drives to Module C

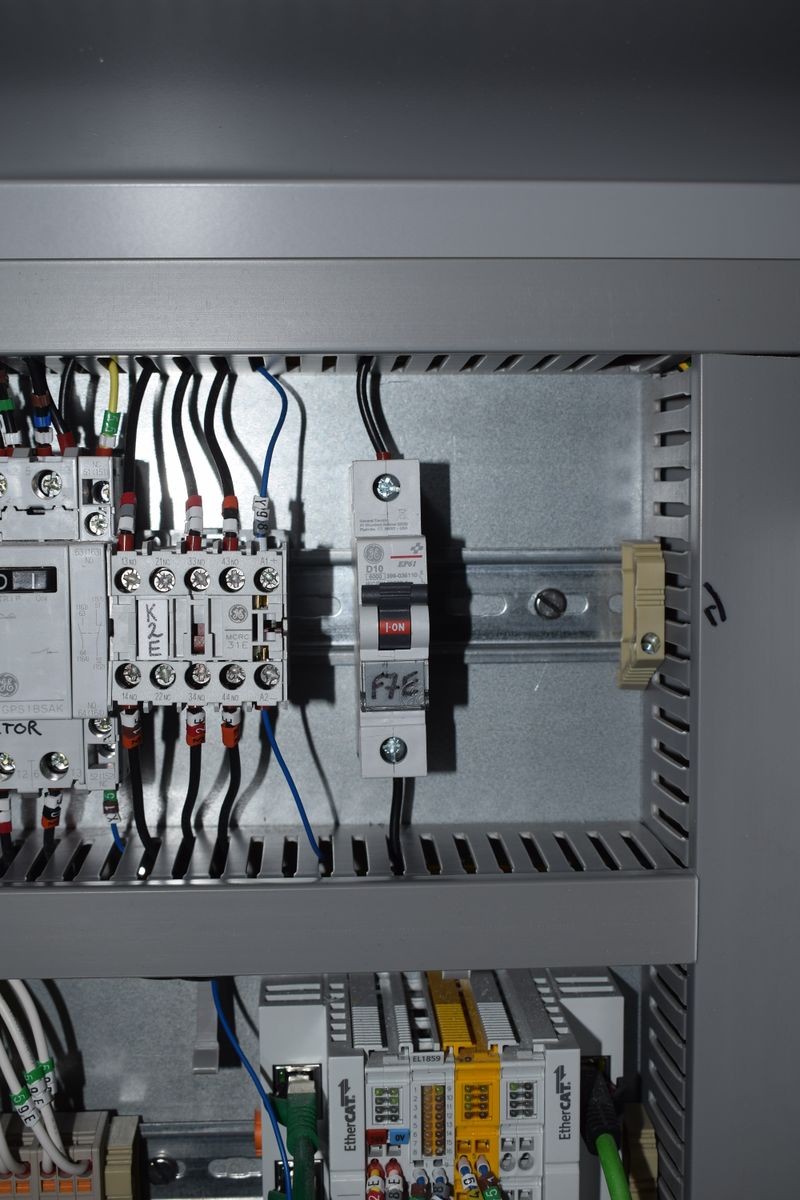

- 20 Étape 19 - Remove breaker and contactor from Module E

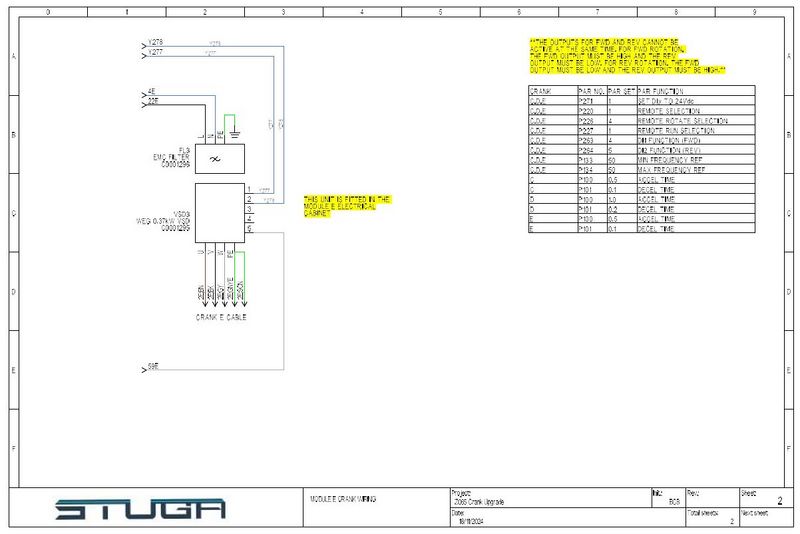

- 21 Étape 20 - Add 10A single pole MCB in Module E

- 22 Étape 21 - Add 1 Off drive to Module E

- 23 Étape 22 - For each WEG drive

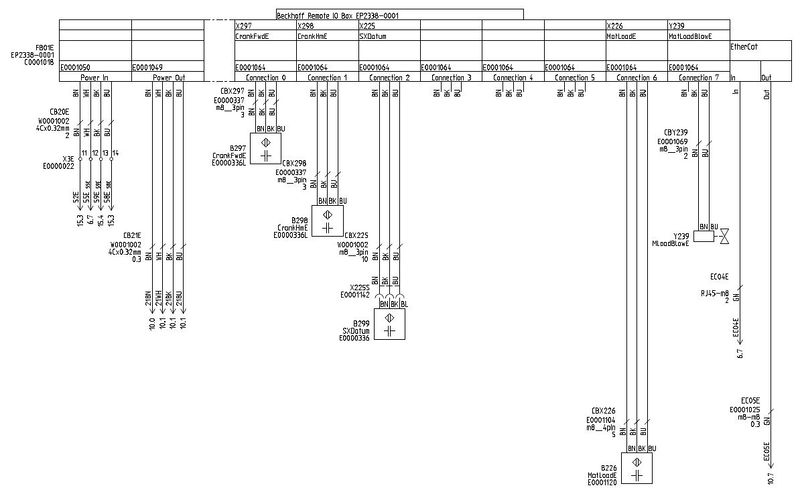

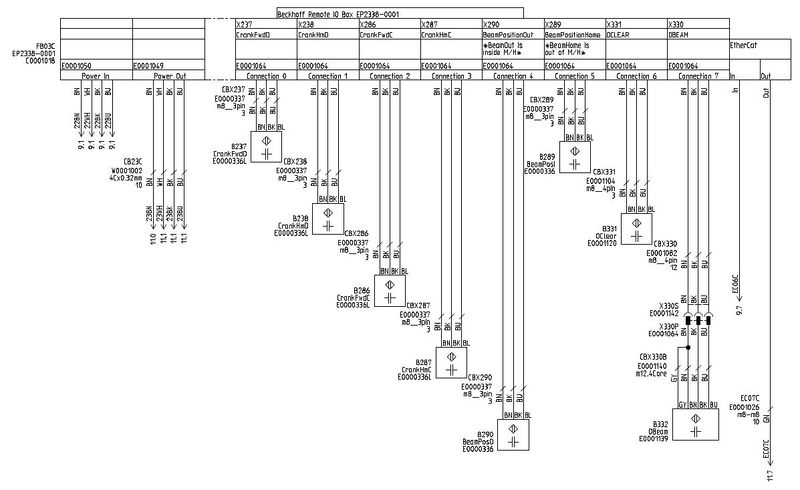

- 24 Étape 23 - Wire Sensor Cables to EtherCAT boxes

- 25 Étape 24 - Latest Front End software installed

- 26 Étape 25 - Map new Links

- 27 Étape 26 - Activate Configuration

- 28 Étape 27 - Add new IO Refs to IODef.mul

- 29 Étape 28 - Latest Front End software installed

- 30 Étape 29 - Programme WEG drives

- 31 Étape 30 - Test Function

- 32 Commentaires

Introduction

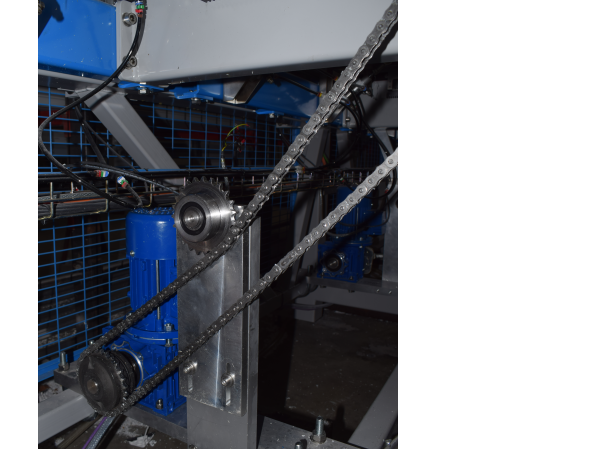

This upgrade replaces the crank arm assemblies on Z065, Z066 and Z067 with a direct drive system to improve reliability

This procedure involves mechanical fitting, electrical wiring and help from a TwinCAT3 competent engineer at HQ for software changes

Étape 1 -

IF EATON DRIVES ONLY* Program Drives before they leave

Running frequency

Control mode

Accel time

Decel time

Étape 10 - Fit Module C Crank Home sensor plate to Arm 5

Sensor cables run to rear Module C cabinet - EtherCAT fieldbus boxes

Étape 11 - Fit Module C Crank Out sensor plate to Arm 5

This one has an extension that may or not be required. See Module D Crank Out Sensor for more info.

Sensor cables run to rear Module C cabinet - EtherCAT fieldbus boxes

Étape 12 - Fit Module D Crank Home sensor plate to Arm 5

Sensor cables run to rear Module C cabinet - EtherCAT fieldbus boxes

Étape 13 - Fit Module D Crank Out sensor plate to Arm 5

This one has an extension

Sensor cables run to rear Module C cabinet - EtherCAT fieldbus boxes

Étape 14 - Fit Module E Crank Out sensor plate to Arm 5

Sensor cables run to rear Module E cabinet - EtherCAT fieldbus boxes

Étape 15 - Fit Module E Crank Home sensor plate to Arm 5

This one has an extension

Sensor cables run to rear Module E cabinet - EtherCAT fieldbus boxes

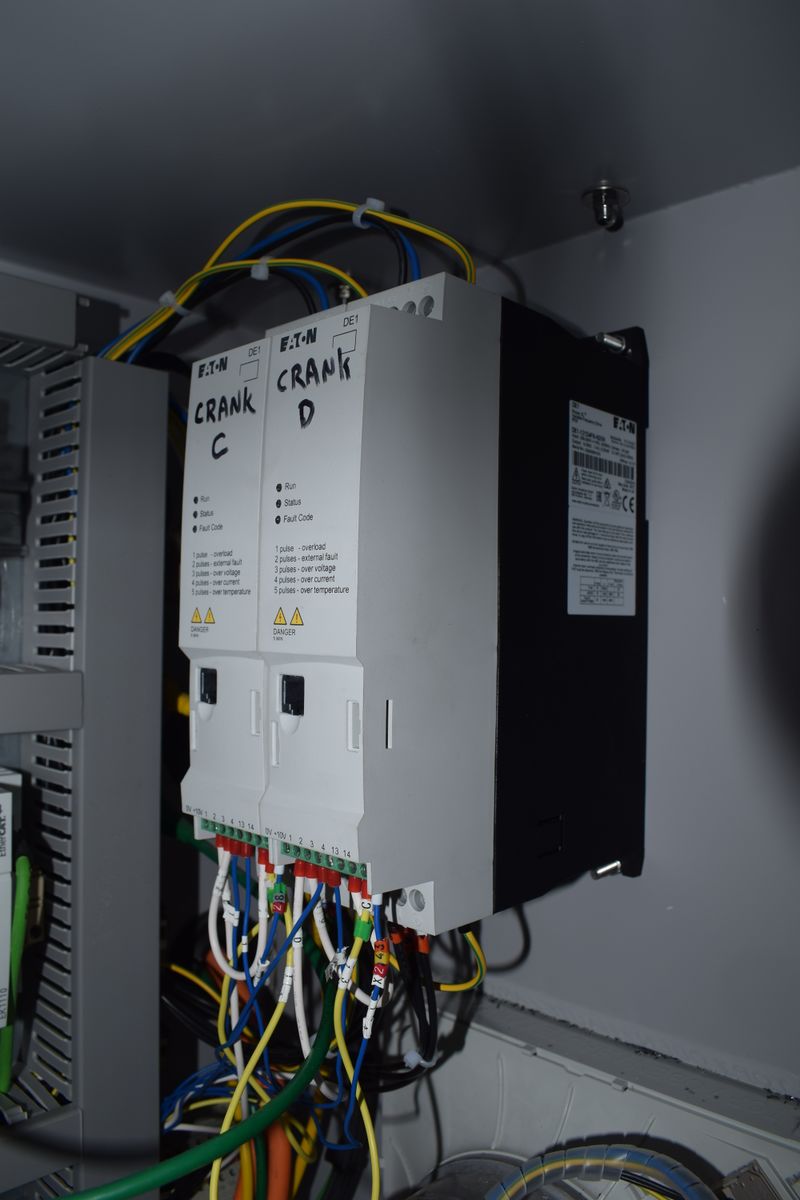

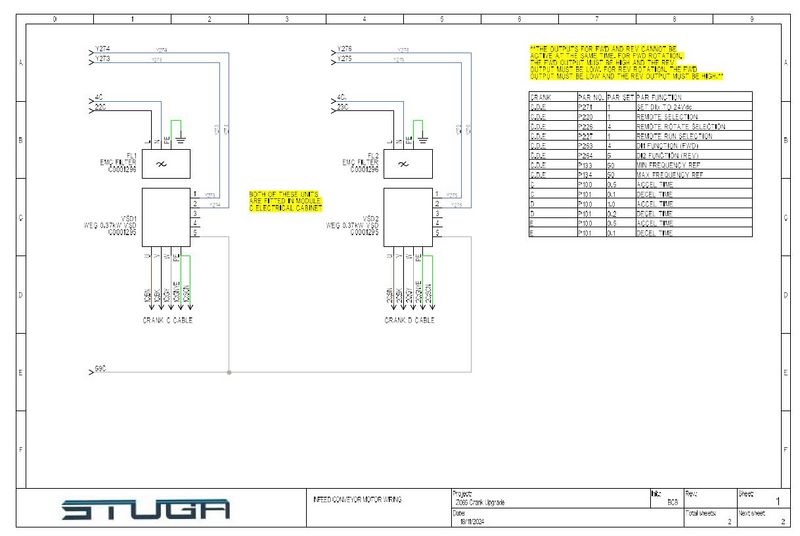

Étape 18 - Add 2 off drives to Module C

May need to move trunking or mount directly to side of enclosure.

Drive can be WEG or EATON

Étape 19 - Remove breaker and contactor from Module E

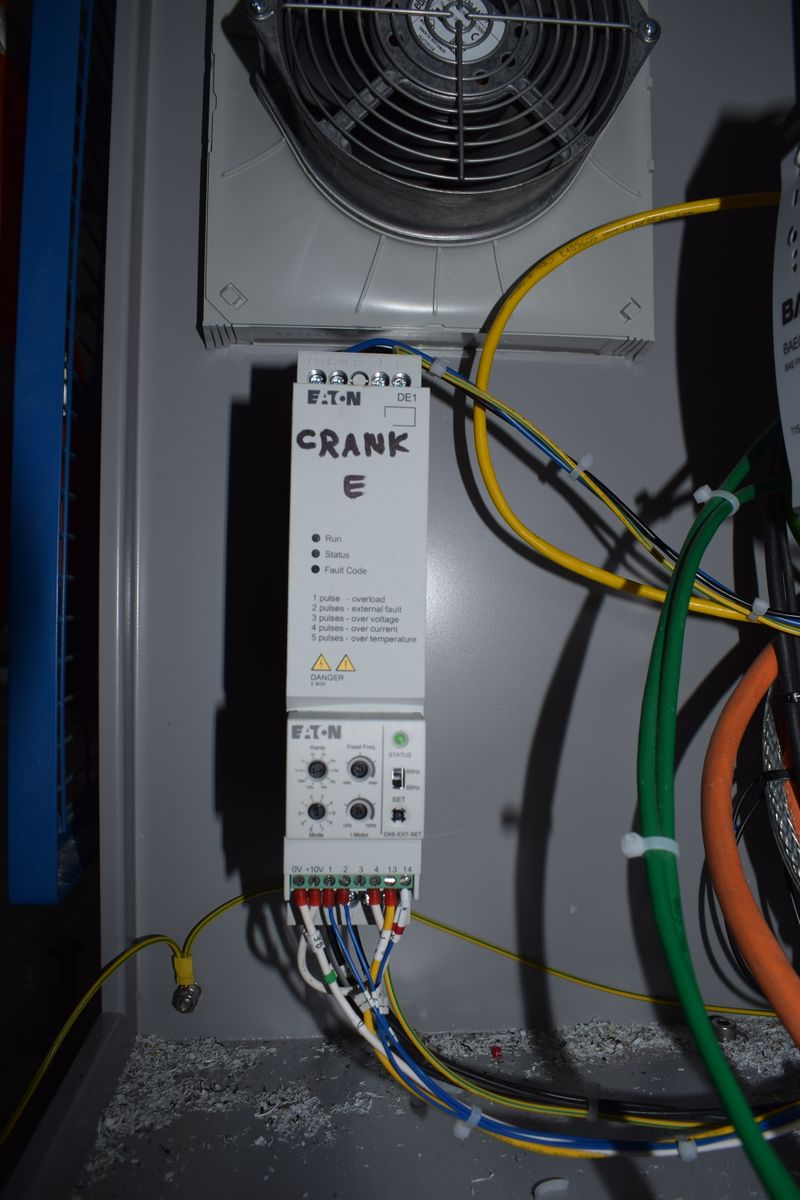

Étape 21 - Add 1 Off drive to Module E

May need to move trunking or mount directly to side of enclosure.

Drive can be WEG or EATON

Étape 22 - For each WEG drive

- Live wire

- Neutral wire

- Earth wire

- 0v supply

- FWD and REV Signals

- Motor cables wire directly into bottom of the drive

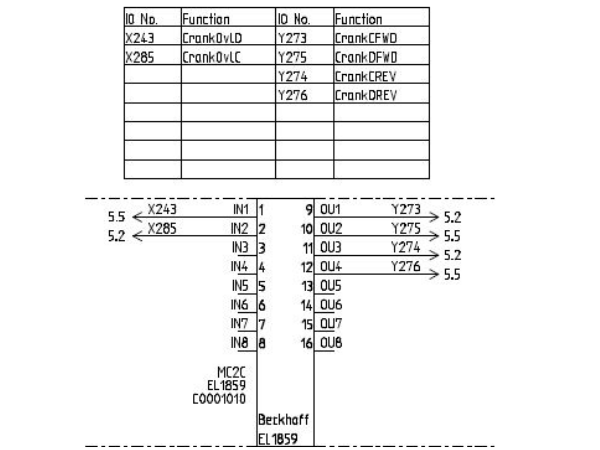

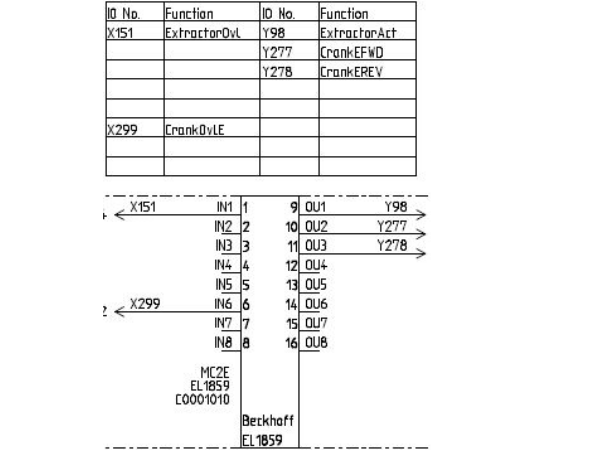

Étape 23 - Wire Sensor Cables to EtherCAT boxes

Module C and D cranks to back of Module C cabinet

Module E crank to back of Module E cabinet

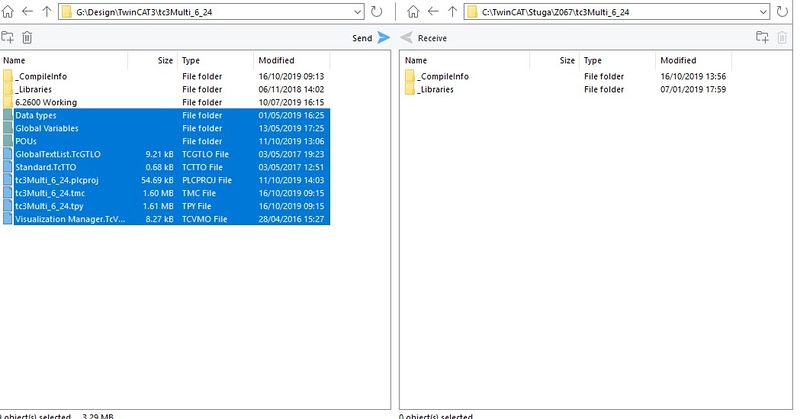

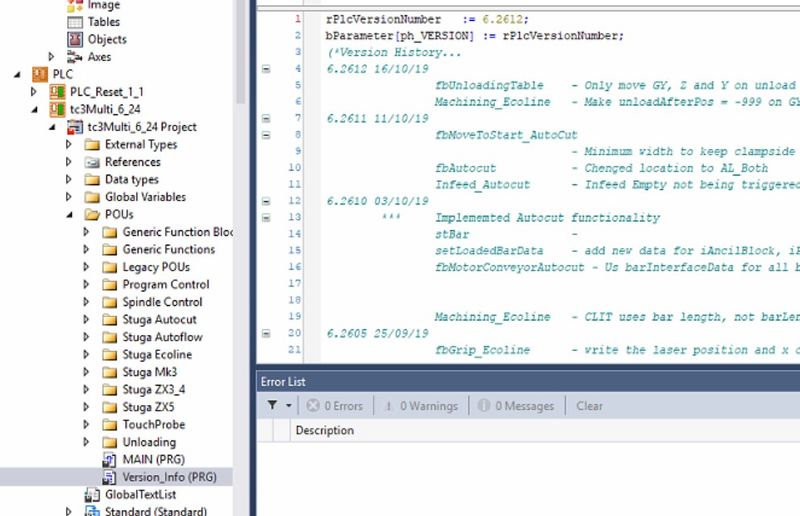

Étape 24 - Latest Front End software installed

- Backup Old multi folder

- Copy in new winMulti version to c:\multi overwriting what is there

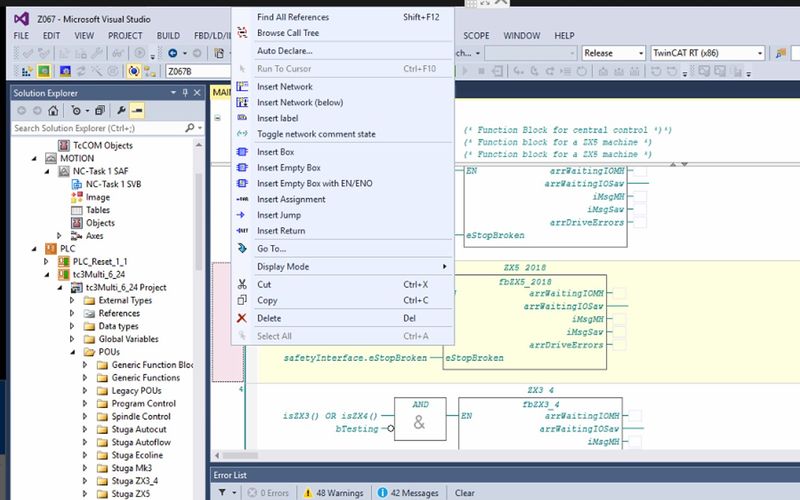

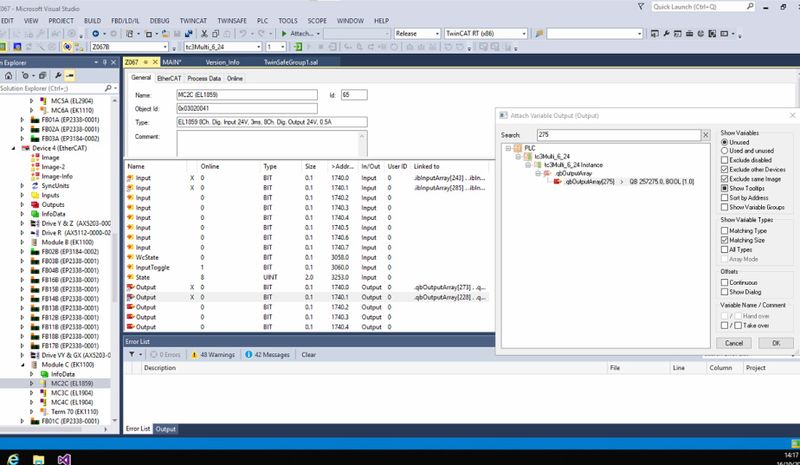

Étape 25 - Map new Links

Overwrite existing links if any exist

See the wiring for MC2C and MC2E in Step 22 for the link IORefs and locations

Étape 26 - Activate Configuration

And restart in run mode when prompted

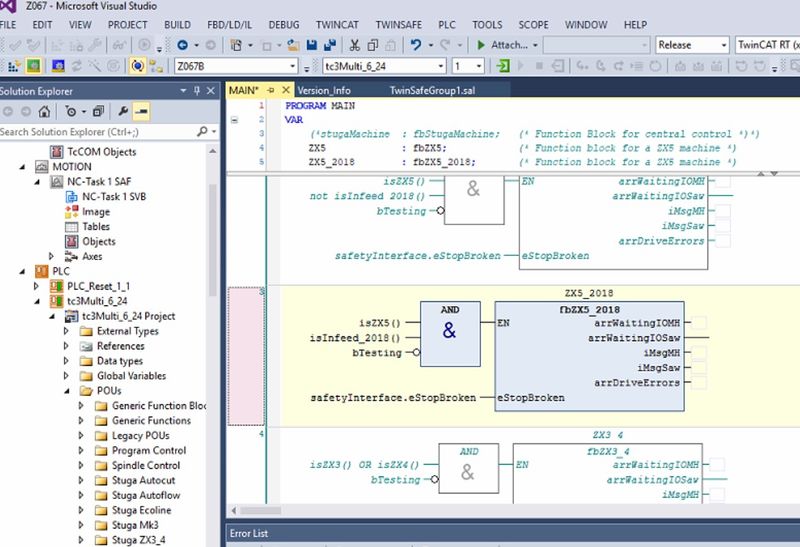

Étape 27 - Add new IO Refs to IODef.mul

Ask HQ to download a relevant IODef.mul file

OuC_CrankFWD,273,2,0,0,False,False,3,8,-,False,0

OuC_CrankREV,274,2,0,0,False,False,3,9,-,False,0

OuD_CrankFWD,275,2,0,0,False,False,3,10,-,False,0

OuD_CrankREV,276,2,0,0,False,False,3,11,-,False,0

OuE_CrankFWD,277,2,0,0,False,True,64,0,-,False,0

OuE_CrankREV,278,2,0,0,False,True,64,1,-,False,0

And these removed

Étape 28 - Latest Front End software installed

- Backup Old multi folder

- Copy in new winMulti version to c:\multi overwriting what is there

Étape 29 - Programme WEG drives

Follow link below for information on programming WEG drives:

Étape 30 - Test Function

- Ensure all Out and home sensors are working and correctly oriented. Home is towards rear of machine, Fwd or Out is towards front.

- Ensure the clutches are set to slip if the crank bottoms out

- Test direction of all cranks (Fwd is towards front). Switch phases on motors if direction needs to change. The PLC has hard code to switch the outputs off when the sensors are covered

Key Pointers

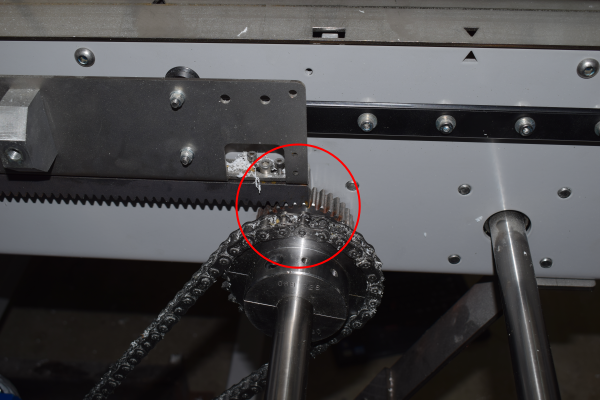

- End stops should be set so the rack can never run off the pinion - always a full tooth engaged

- Each crank motion stops when the input is seen, and then decelerates. Therefore, set the crank input position to allow for this deceleration before hitting end stop. Normally about 30mm

- The crank clutches should be set to slip before damage is done to the crank end stops in the event that the sensors do not work

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português