Describing the changes and enhancements to the trim cut and throwaway chunk cutting on Stuga Sawing

Problem

older versions of software struggled with different offcut lengths, particularly on cill saws where the profile is extra wide (>120mm). Previous attempts to improve the waste disposal involved moving short, waste offcuts to the start of the bar, rather than the end. The waste cutting algorithm then had to cut these large pieces into sizes small enough to fit down the chute.

Different angles and wide profile caused exceptions which caused pieces to get jammed in the chute and in the clamping system

See also Moving Awkward Waste Offcut to Start of Bar

Solution

The algorithm has been rewritten to simplify this for any profile width and starting cut angle. The bar view has also been updated to accurately reflect the positions of all of the waste cuts on the bar

The rules are as follows:

Shift Waste To Start

If the remainder is less than "throwaway" parameter, then shift the remainder to the start of the bar.

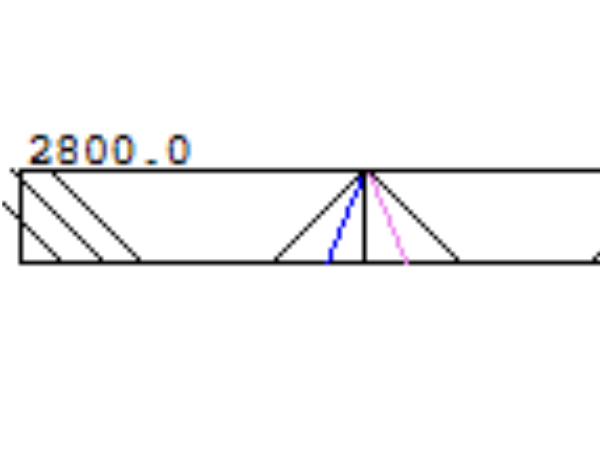

Picture shows a sill with a throwaway set to 500mm. The waste is shifted to the front end of the bar

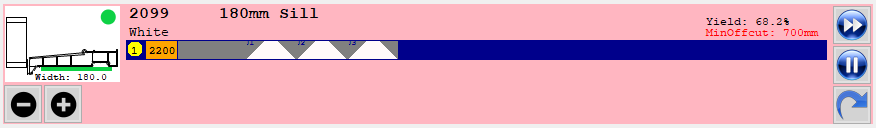

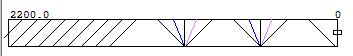

Picture shows the bar view, with the chunk cuts at the start (throwawayChunkSize set to 100)

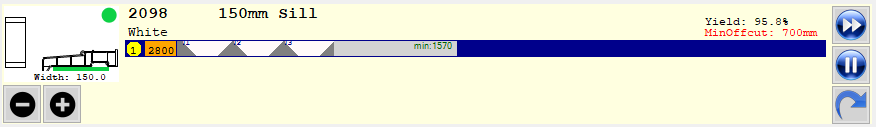

If the remainder is greater than "throwaway" parameter, then eject waste onto the outfeed table at the end of the bar - the front end of the bar will still include any trim parameter

Throwaway Chunk Size

This waste will then be disposed of in small chunks to fit down the chute. Size of the chunks is determined by "throwawayChunkSize" parameter

Half and Quarter Triangles

The system also looks at how big the triangular offcut will be between two mitre cuts (or a mitre and square cut). if the piece is going to be bigger than the throwawayChunkSize, then it will cut half and quarter triangles to fit the offcut down the chute. (these can be seen in blue and red on above picture

Chunk angle

The angle of the trim cuts at the start of the bar now match the first cut on the bar, which makes for a more consistent run. eg, if the first cut is 135 degrees, all the chunk cuts will be at 135 degrees

Profile Specific Adjustment

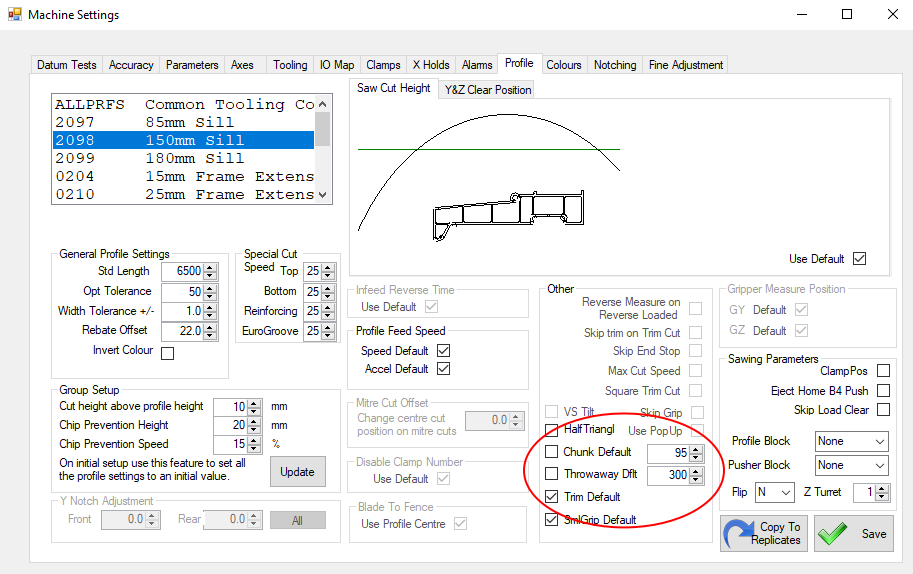

Each parameter (throwaway, throwawayChunkSize and trim) can be adjusted individually per profile from the profile setting screen. This allows fine adjustment to dispose of particularly wide profiles without slowing down the process for smaller profiles. if the box is ticked, it will use the default main parameter. If unticked, the profile specific parameter can be adjusted.

Application Notes - S095

On S095 machine, it was found that the throwaway could catch the outfeed clamps on eject, and it was better dealt with by chopping it up at the beginning. The throwaway for the cill profiles was set at 700, which cured a lot of problems of the end offcut catching on ejecting the throwaway.

See also Moving Awkward Waste Offcut to Start of Bar

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português