An issue has been found on ZX machines using TwinSAFE for the saftey system where under a certain condition can mean that the MH Doors can be opened whilst the V Notch Blades are spinning. This document provides all the required information to change the wiring on the machines to make the system safe.

Sommaire

What is the issue that needs resolving?

The operators are able to open the Multihead doors whilst V notch motors are still spinning.

Root cause was the front solenoid lock full of swarf preventing the locking mechanism working.

This has defeated the safety system because the locking safety switch has not been fed back into the safety system.

This only affects TwinSAFE machines:

Z054, Z056, Z057, Z063 to Z070

How do we solve the issue?

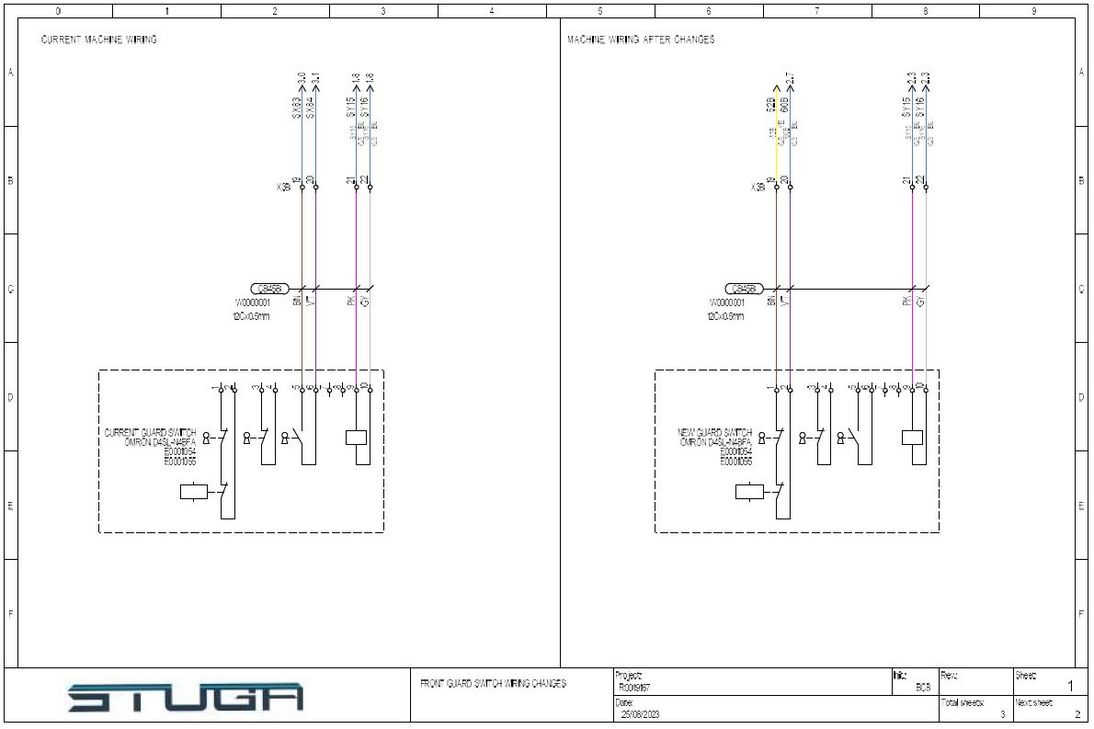

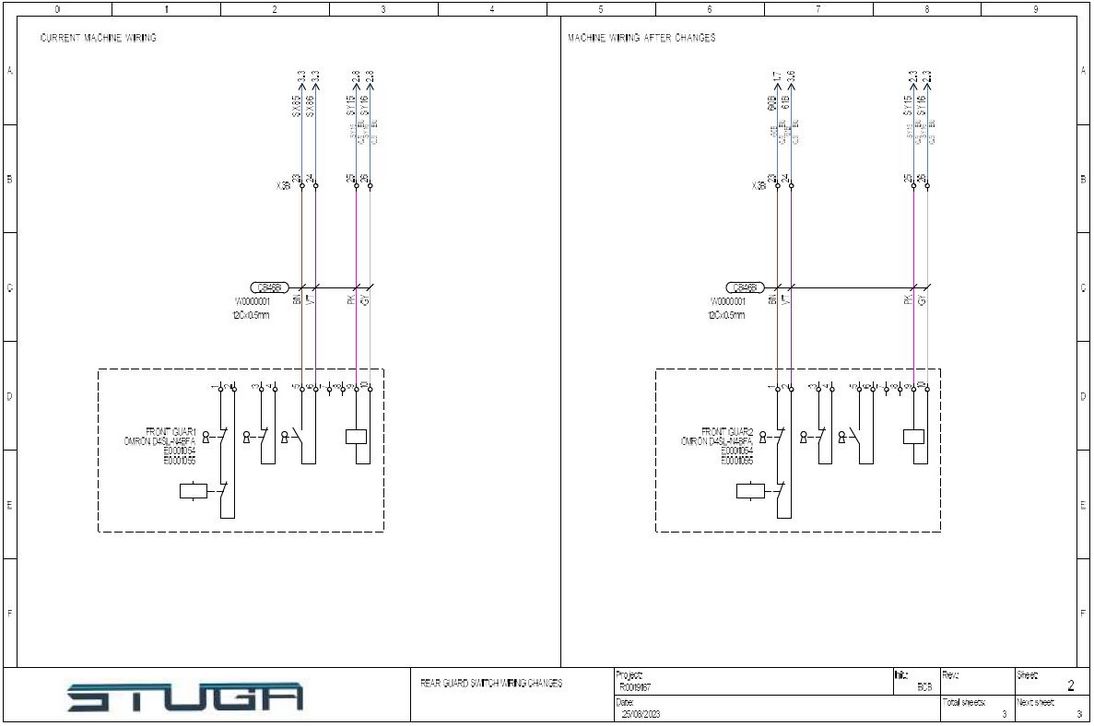

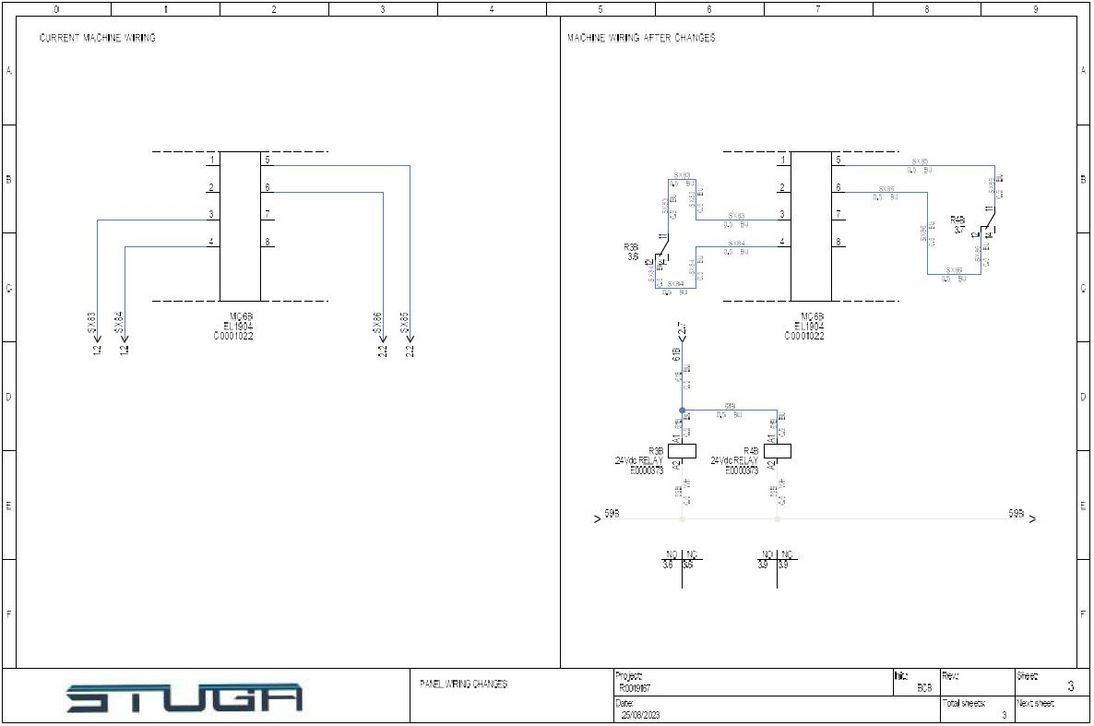

The wiring in the system needs to be changed to utilise more of the safety functions inside the safety switches that are fitted to the doors. The diagrams below show how the doors are wired from factory and how the wiring should be changed to make the machine safe.

The diagrams above show that we are changing the wiring inside the guard switch to not only monitor the status of the key inside the switch but also the state of the solenoid (lock). This now means that 2 conditions need to be met before the system is deemed safe by the TwinSAFE controller. The key needs to be in the switch and the solenoid needs to be in its locked condition. If the solenoid is manually set to unlock, the system will recognise this and will not allow the starting of the V Notch Blades.

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português