On a flowline / ZX with separate winSaw program on saw side, the software works by continually increasing the Bar Queue with every bar cut. An issue has been found that if the operator rarely resets the program, it can build up in size and get “bloated” to the point where it does not perform correctly with the following symptoms: • Missing / delayed labels • Slow updates / performance • Long time to start cutting a bar after loading • Reprinting label delays

Sommaire

Problem

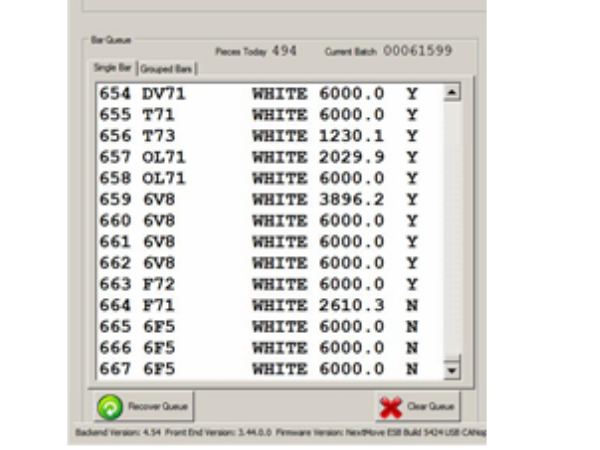

Picture shows a queue where the saw software has not been restarted for 2 days, with a queue of 667 bars. This machine was increasingly missing labels as the queue size increased.

Solution

The solution is very simple.

Keep the bar queue below 200 bars by exiting to windows and restarting the saw software. Note: You do not need to restart windows or switch the machine off, just restart the saw software.

This normally happens naturally on daily basis, because the operator shuts the machine is shut down. However, in some cases, the machine is left on overnight, and the bar queue is then not cleared and builds up day by day.

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português