Removal of the pinch point created between the conveyor belt and the extractor swarf hood

Objective

Removal of the pinch point created between the conveyor belt and the extractor swarf hood

Procedure

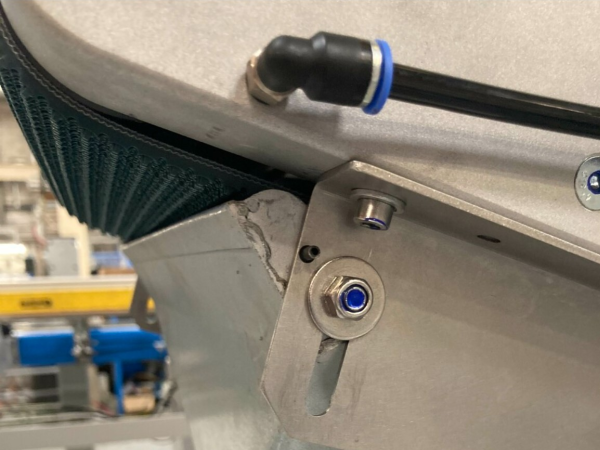

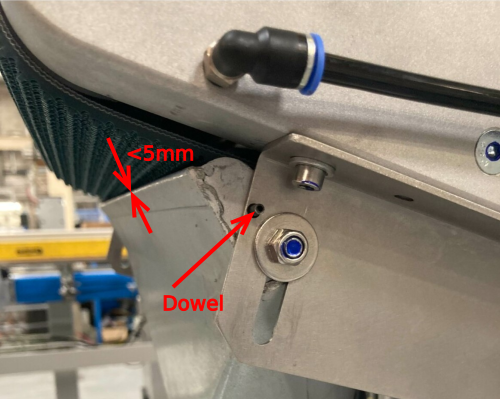

- Ensure gap is less than 5mm between nozzle and belt.

- Fit a 3 mm roll pin drilled through both parts to stop bolts acting as a pivot

Testing

- Measure gap between belt and hood, ensure <5mm

- Ensure the dowel fixing is secure and hood cannot be knocked out of position

Completion

This modification is expected to take no longer than 15 minutes to complete.

Completion is when:

- Testing completed

- Device Magic app updated for this task, with time taken and photo evidence recorded

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português