How to overcome the minimum residual distance (the minimum square cut portion) of a Y notch on an Autoflow

Sommaire

Problem

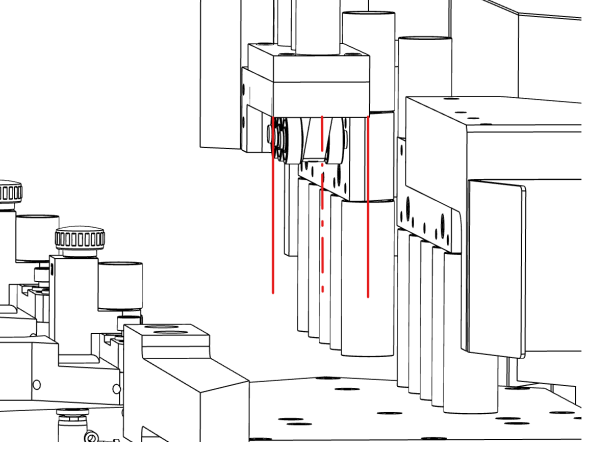

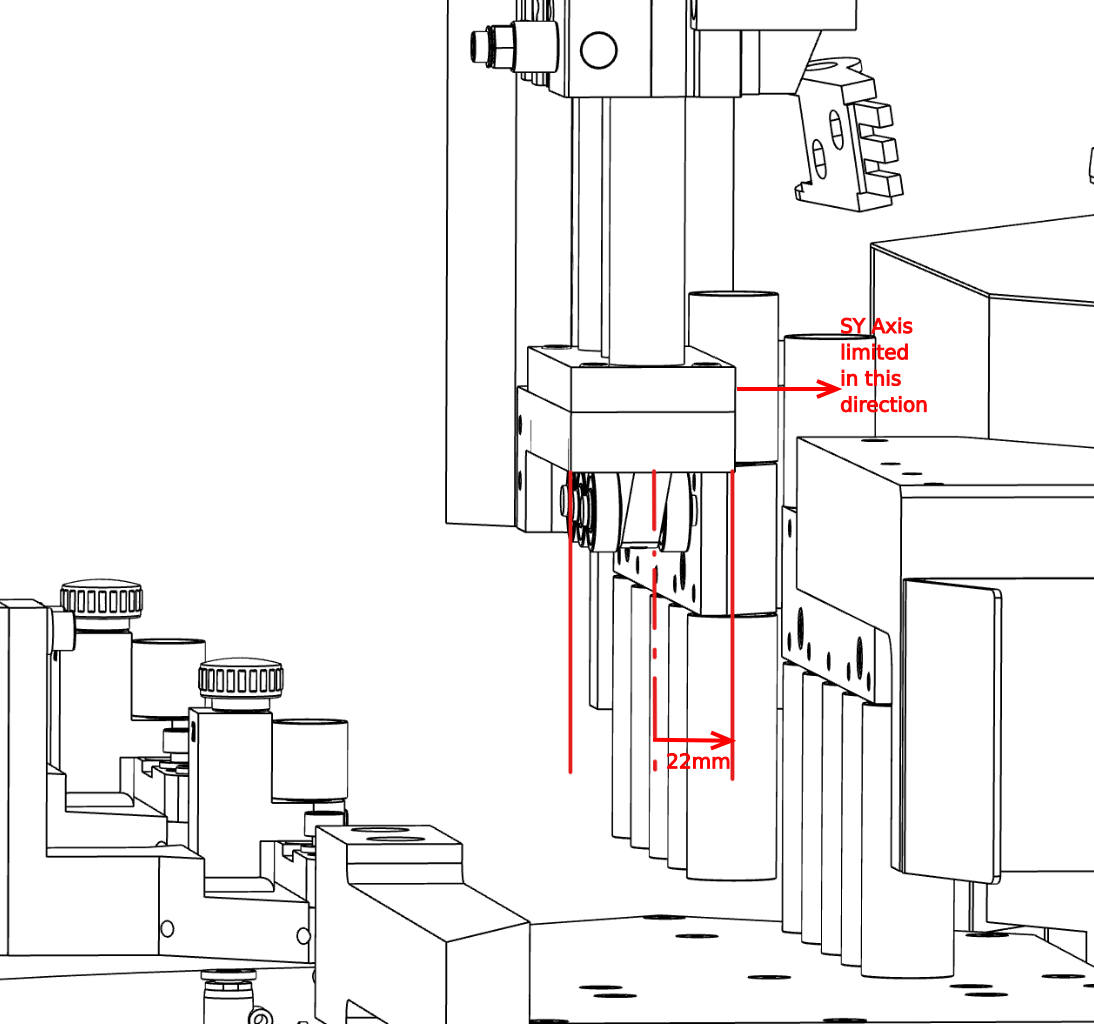

On some Autoflow machines, the rear clamping height restricts the SY axis mechanism from moving towards the rear. This is because the top roller clamp is located on the saw rotation centreline (to allow the chip probe deflectors to work). The clamp has a thickness of around 44mm, so it will interfere with the backfence when the SY position is half this width (22mm).

This gives a minimum residual of 22mm., which is a problem when (for instance) a slim outer frame is 50mm wide, and it needs a 35mm deep Y notch. The residual will be 50-35 = 15mm, less than the minimum of 22mm.

Solution

The solution is the same as that for a ZX5

TB0434 Setting Up Deep Y notches on ZX5

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português