How to set up a Stuga Flowline / ZX machine for Flush Sash modification

Sommaire

Problem

When this profile was implemented originally in 2020

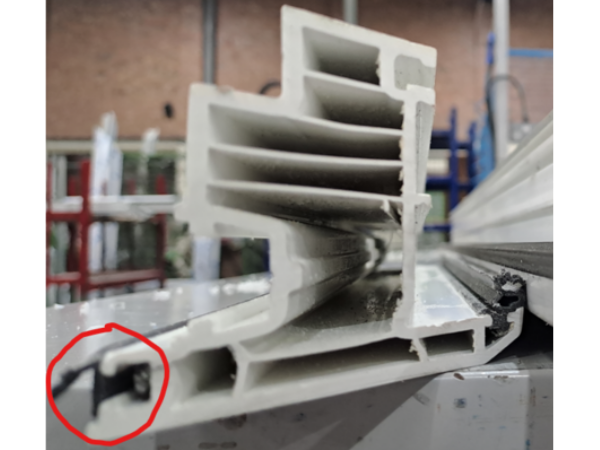

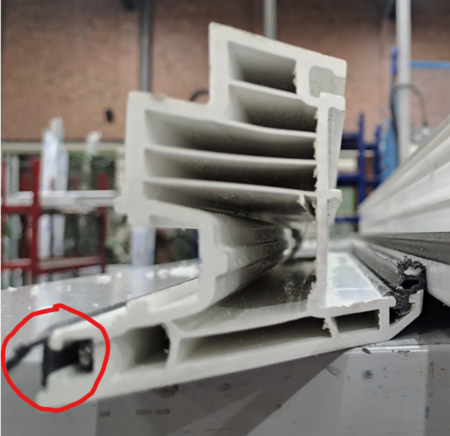

- The profile has an overhanging gasket that is complicated and had never been dealt with before

- It compresses in the clamps, so is narrower in the clamps but wider when cut, meaning the machine cuts to the plastic size, not the gasket size (which is important)

- A work around for this was structured which involved foxing the machine into thinking the profile included the gasket so it cut it longer.

- This meant adding a fiddle factor into the link file to reduce the cut length size

- The profile was being cut in "Centralise" mode, which means any deviation in physical profile width will have a 2x error in the cut length

- The deviation comes from how much the gasket compresses.

- The difference in compression changes between white and black profile.

- I think it is safe to consider that this may also change between profile batches and outside temperature.

- If the machine is set up CORRECTLY, (correct width, not in centralise mode) then the plastic size is correct, but you get a back cut on the gasket.

The backcut happens because the saw blade position is calculated to waste as little profile as possible. Therefore a better work around is to increase the gap between the pieces, wasting a little more, but leaving the gasket in mid air.

Solution

An additional profile parameter "extraGap" has been added to profile extra parameters, available on the profile settings screen. This is implemented from front end version 6.6.3.0.

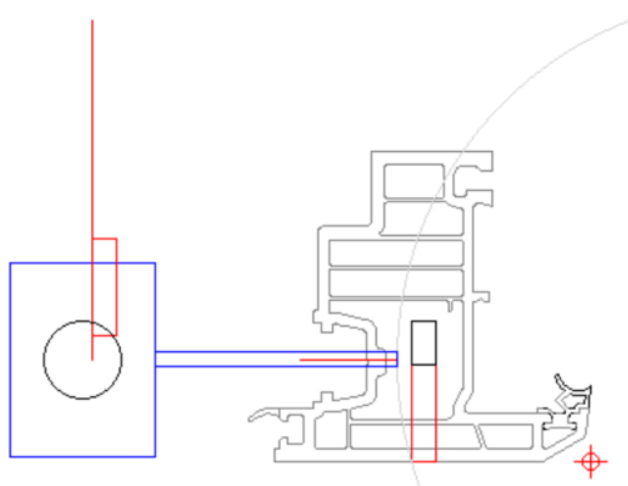

| Reverse loaded | The profile must be reverse loaded to ensure the best and most reliable contact with the plastic to the rear roller fence.

The eurogroove should face away from the backfenceThe reverse load parameter in the profile ops should be set

|

| Centralise Mode | If a narrow profile(<70mm) (like 70216) is reverse loaded, there is a risk that the mitre cuts will create a problem where the mitre cuts are in the wrong order. This is driven by the trigonometry of the saw blade x axis position for mitres. To overcome this, the profile settings should switch on centralise mode |

| Piece Length | The length sent by the software company must be the cut length. No offsets or fiddles factors for the length need to be used |

| Centralise Pressure | Ensure the centralise pressure is enough to reliably grip the profile |

| Clamps set too low | Ensure the saw clamps are not set too low which prevents the profile reaching the backfence |

| Software version | Update is done on version 6.6.3.0. Note this is only available on machines with the Beckhoff control system, NOT on Nexmove controlled machines |

| widewaste parameter | In sparams.saw - widewaste=20 |

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português