Installation of the Igus 2500 Energy chain on Stuga machines

Introduction

There have been reliability problems with the use of the energy chain type "B15" (15.050.048..), prompting the sourcing of a more rigid structural type. The following design points have been taken into account

- The 2500 type chain from Igus is the correct system for our application. It is a standard type and generally stocked

- Using the 2500.03 type from this range is has a taller yet narrower cross section, but is ample for the application

- A bend radius of 100mm is specified by Beckhoff for the cable, but the decision has been made to reduce down to 55mm. This decision is based on the success / longevity of upgrades done in the field with 55mm radius and the fact that the 100mm bend radius will not fit in all applications. Using the 55mm bend radius allows a "one size fits all" for all Stuga applications

- The chain should be "Openable Outside" to enable a drag-style application on the inner faces

- Cable separators should be added every 10 links to help keep the cables separate and the Beckhoff cable as central as possible

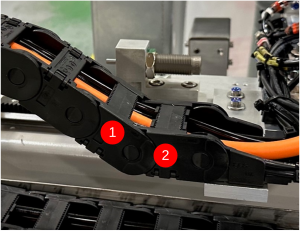

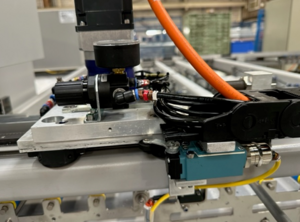

- Cable tie points on the brackets are 100% essential. These "combs" are a clip on addition

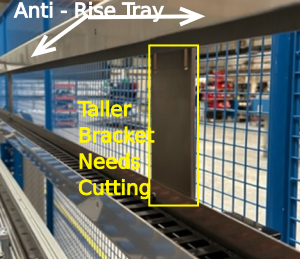

- A rigid chain, coupled with a smaller bend radius removes the need for the "anti-rise" trays and the vertical members holding this assembly in the air

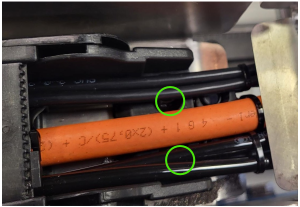

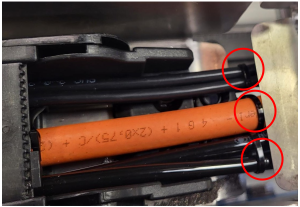

- The Beckhoff cable should be untwisted before feeding into the energy chain

Installation Rules

| 1 | Check the correct components have been sent before assembly - the Igus part numbers are moulded into the side |

||

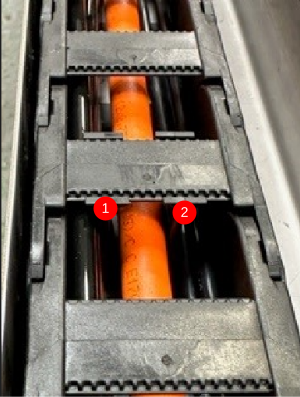

| 2 | Use Cable Separators, two are needed at each location (every 10 links)

Beckhoff cable in centre |

||

| 3 | Untwist the Beckhoff cable before installation | ||

| 4 | Fasten the bracket down, NOT the Cable tie comb | ||

| 5 | Cable tie all cables and pipes BOTH ends | ||

| 6 | Ensure the first two links are reversed on the servo end |

| Part No | Igus Code | Photo | Description | Notes |

|---|---|---|---|---|

| A0001113 | 2500.03.055.0 | Energy Chain: Series 2500.03 55mm Bend Radius | Supplied in metre units | |

| A0001110 | 2030.12PZB | Energy Chain Bracket Set Non-Pivotable With Cable Tie connection | Supplied as a Pair

Flowline and ZX3/4 uses NON-PIVOTABLE ZX5 uses Pivotable type

| |

| A0001114 | 2030.34PZB | Energy Chain Bracket Set Pivotable With Cable Tie connection | ||

| A0001112 | 25.1.1 | Energy Chain Separator for 2500 Chain | Two separators required every 10 links |

Installation ZX5 - Machining Centre Side

| Upgrade PartNo | R0015143B |

| Links | 6.0m -111

6.5m - 116 |

| Disposal | Remove the upper "Anti-rise" trays if fitted

The anti-rise system has taller brackets that will need to be cut down level with the tray, as these upstands create a vertical barrier that the chain could feasibly hit. |

| Special Notes | |

| Photos |

Installation ZX5 - Saw Centre Side

| Upgrade PartNo | R0015144B |

| Links | 6.0m - 94

6.5m - 99 |

| Disposal | Remove the upper "Anti-rise" trays if fitted |

| Special Notes | Remove anti rise tray and trim taller brackets (see Machining Centre side above) |

| Photos |

Installation Flowline - Machining Centre Side

| Upgrade PartNo | R0019175B |

| Links | 6.0m - 87

6.5m - 92 |

| Disposal

ONLY if anti-rise trays fitted |

ONLY IF the anti-rise trays are fitted

Note: this only allies to a specific set of recently upgraded flowlines that have a tray modification and the "B15" energy chain. THIS DOES NOT APPLY TO THE MAJORITY OF FLOWLINES Cut down the upper "Anti-rise" trays if fitted or replace with the original trays from a flowline 6.0mtr H0006746 1 off H0006747 1 off H0006751 1 off

add H0007897 1 off |

| Special Notes | Very important to use the Non-Pivot brackets on this machine to ensure the energy chain passes over the datum switch

|

| Photos |

Installation Flowline / ZX3 / ZX4 - Saw Side

| Upgrade PartNo | R0019176B |

| Links | 6.0m - 87

6.5m - 92 |

| Disposal

ONLY if anti-rise trays fitted |

ONLY IF the anti-rise trays are fitted

Note: this only allies to a specific set of recently upgraded flowlines that have a tray modification and the "B15" energy chain. THIS DOES NOT APPLY TO THE MAJORITY OF FLOWLINES

H0006747 or o/h H0007631 H0006748 or o/h H0007411 H0006751 or o/h h0007363

add H0007897 1 off |

| Special Notes | |

| Photos |

Installation ZX3 / ZX4 - Machining Side

| Upgrade PartNo | R0019253 |

| Links | 6.0m - ??

6.5m - 108 |

| Special Notes | |

| Photos |

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português