Commonly used during sawing on Z transoms, the Z block operation is used to fasten the profile, making sure it does not move during sawing.

Introduction

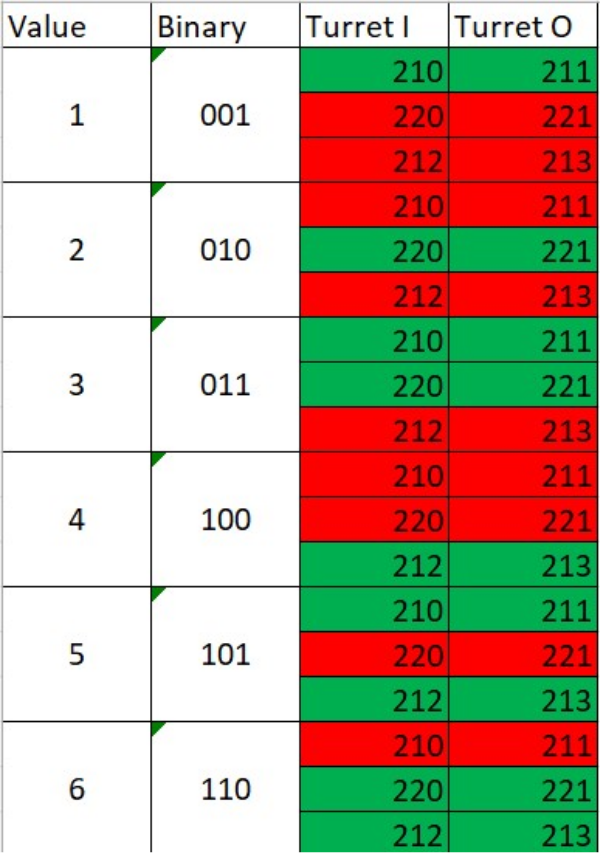

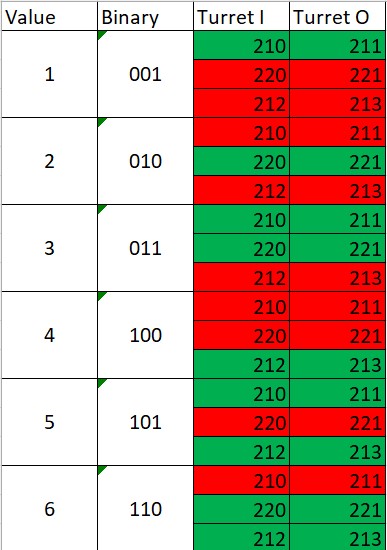

Commonly used during sawing on Z transoms, the Z block operation is used to fasten the profile, making sure it does not move during sawing. There are 6 possible states the z block can be in. Each of these can have a different length of protrusion for different profiles.

12 x M8 Screws

12 x M8 Nuts

12 x wire numbers 1 - 6Étape 1 - Turret A - Find Position 1 on the Turret

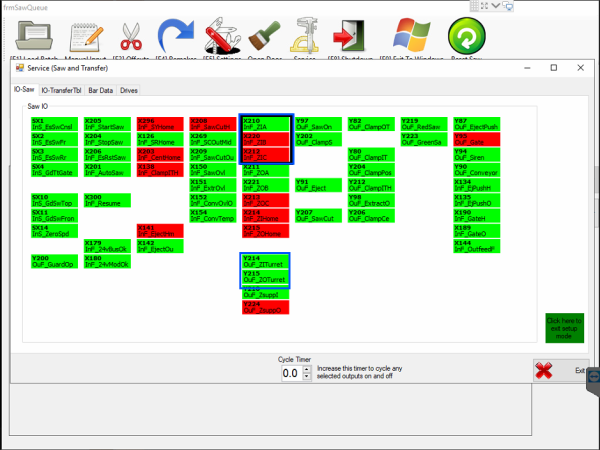

On the Service > IO tab use output Y214 to turn the infeed turret.

Étape 2 - Check the Binary Count of the Turret

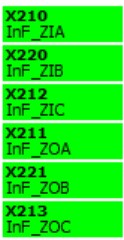

Each turn of the turrets will change the binary state of the inputs X210, X220 and X212.

Use the table in the picture to ensure the count goes 1-2-3-4-5-6 and back to 1

Étape 3 - Repeat for the outfeed turret

Use Y215 to pulse the outfeed turret

Each turn of the turrets will change the binary state of the inputs X211, X221 and X213

Use the table in the picture to ensure the count goes 1-2-3-4-5-6 and back to 1

Étape 4 - Check the Labelling is correct

The turrets should be labelled 1-6 with pneumatic pipe markers

The turret position should be written on the top of each turret in permanent marker

Étape 5 - Check Turret Home for Infeed and Outfeed turret

X214 InF_ZIHome should signal high (red) when the infeed turret is home

X215 InF_ZOHome should signal high (red) when the outfeed turret is home

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português