How to solve the long term issues with the SR Axis Energy Chain on an Autoflow

Sommaire

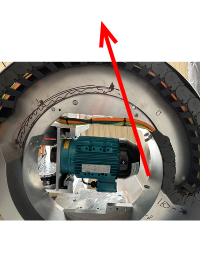

Problem

The SR Axis energy chain on an Autoflow has historically been unreliable and confusion has surrounded how to set it up. It is not clear how the chain should be inserted and how to prevent the system form folding back on itself. The consequences of failure in this are can be severe in both parts costs and the time / expertise to resolve.

Following an investigation GMG / March 2023, in conjunction with from Igus, the following major issues were identified:

| Issue | Description | Resultant problem | |

|---|---|---|---|

| 1 | Reverse Bend Radius same as "Normal" bend radius | Energy chain used has a forward bend radius of 60mm AND a reverse bend radius of 60mm. This means the chain can be inserted either way round and it will appear correct. However, the reverse bend has inherent friction, meaning it resists normal unwinding behavior. |

No obvious which way round the chain should be inserted |

| 2 | Reverse bend radius too small | RBR should follow the profile of the inner ring. This has a radius of 100mm, not 60mm | Chain wants to bunch up / kink instead of unravelling smoothly |

| 3 | Inner guide rail could be longer | The internal guide rail finishes too early, meaning the chain has more chance to kink out of control. | Chain wants to bunch up / kink instead of unravelling smoothly |

| 4 |

- Energy chain used has a forward bend radius of 60mm AND a reverse bend radius of 60mm. This means the chain can be inserted either way round and it will appear correct. However, the

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português