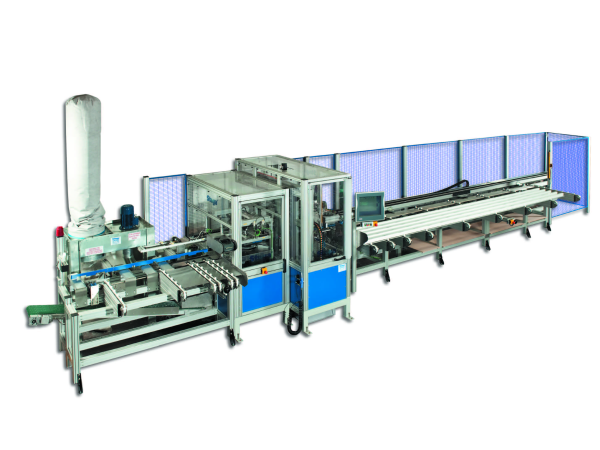

Autoflow Mk1 - 3 Daily Maintenance Procedures to be carried out by Operators

Difficulté

Facile

Durée

15 minute(s)

Introduction

The following areas should be attended to daily

This routine should take no more than 15 minutesÉtape 1 - Daily Tests

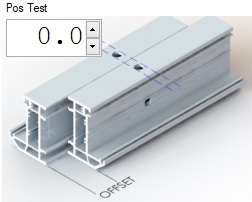

To check the machine is ready for production, a couple of simple tests can be run

- Datum Test

- Pos Test

Étape 2 - Infeed Table

- Thorough blow down of the infeed module

- Blow down of the gripper carriage

- Wipe the offcut measurement sensors

- Remove swarf from grip finger teeth

Étape 3 - Machining Centre Module

- Thorough blow down of the Machining Centre Module

- Visually check tooling for damage or swarf buildup

- Check the V notch blades are not buckled

- Check M/C rollers for tape build up

- Empty M/C waste boxes if required

Étape 4 - Saw Module Cabinet

- Thorough blow down of the saw module

- Remove any loose waste pieces in the saw

- Check the the rear rollers and saw beds for profile tape buildup

- Check saw blade pulley belts (tension/replaced as required)

- Empty saw waste box if required

- Empty extraction waste pieces from cyclone / hopper box

Étape 5 - Saw Outfeed

- Thorough blow down of the saw outfeed

- Thorough shake of the extraction top cloth bags

- Change lower extraction bags as required

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português