The saw “Y drive” on a ZX5 is limited in its depth range to +/- 20mm from the centreline of the profile, and 20mm from the backfence. This is fine for most normal Y notching, but there are combinations when a particularly deep Y notch is required. This process is also useful on an Autoflow where the SY axis distance is limited by the backfence / top clamp interference

Sommaire

Similar problem is apparent on Autoflows see Minimum Residual on Autoflow Machines

| TB Number: | 0434 |

| Originator: | Gareth Green |

| Machine: | ZX |

| Date: | 04/04/19 |

| Circulate to: | Service; |

| Title: | Setting Up “Deep” Y notches on ZX5 |

Problem

The saw “Y drive” on a ZX5 is limited in its depth range to +/- 20mm from the centreline of the profile, and 20mm from the backfence. This is fine for most normal Y notching, but there are combinations when a particularly deep Y notch is required.

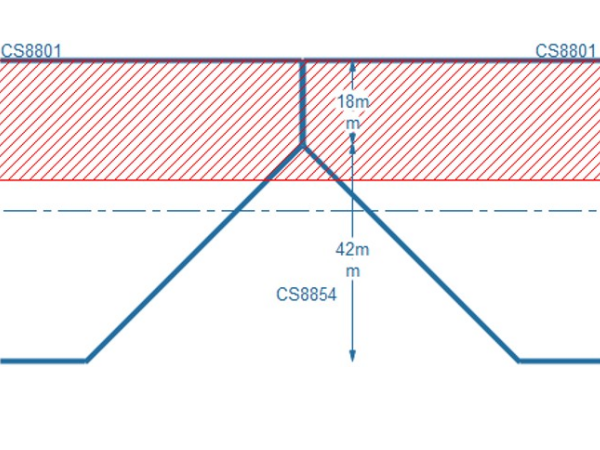

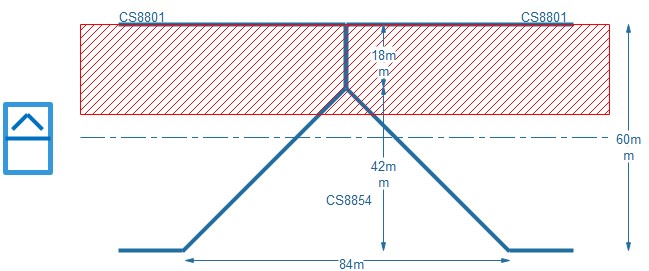

For example: Reversible windows - have a wide transom (84mm) and narrow outer frame (60mm)

This gives a Y notch depth of 42mm in a 60mm wide profile, leaving 18mm “residual” square cut on the end. This is outside the minimum threshold of 20mm from the backfence and the saw centraliser would bottom out.

Solution

To solve this problem, the machine has an automatic feature to allow the use of a SQCUT to create the Y notch – this operation uses the 10mm datum tool to make a square slot on the machining centre side, and then the saw side cuts a mitre to finish it off.

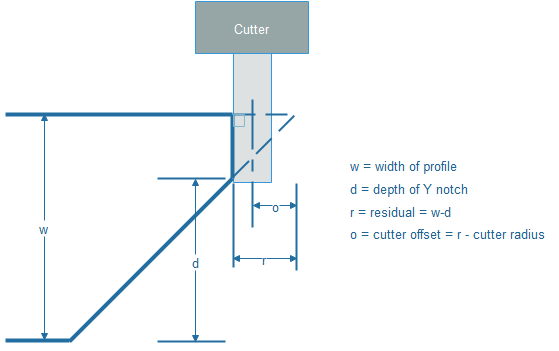

The software has to increase the length of the part to allow for this, using the following calculations:

These calculations are done automatically from the dimensions of profile width and Y notch depth. The Y notch depth is taken from the tool code (YFL475 will give a 47.5mm depth), plus the globalYDepthAdjustment parameter.

Application

To enable this feature carry out these steps:

| Step | Instruction |

| 1 | Ensure Front End version 6.3.4.0 or later is installed |

| 2 | Set the minYNotchResidual parameter correctly

ZX5 - 21mm Autoflow Mk4 -22mm |

| 3 | Identify the profiles and tool codes that will give you a residual of < minYNotchResidual |

| 4 | Create a new specific operation entry for these Y notch depths on the profiles affected.

|

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português