| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 18 : | Ligne 18 : | ||

|V and Y notch depths inaccurate | |V and Y notch depths inaccurate | ||

| | | | ||

| − | | | + | |All except Saw |

|- | |- | ||

|Kerf | |Kerf | ||

| Ligne 24 : | Ligne 24 : | ||

|Saw cuts correct for mitre cuts but not square cuts, or vice versa | |Saw cuts correct for mitre cuts but not square cuts, or vice versa | ||

| | | | ||

| − | | | + | |All except ecoline |

|- | |- | ||

|Laser hole swarf | |Laser hole swarf | ||

| Ligne 38 : | Ligne 38 : | ||

|Random operation positions, particularly on heavier profiles | |Random operation positions, particularly on heavier profiles | ||

| | | | ||

| − | | | + | |All |

|- | |- | ||

|Rack Calibration / Scaling | |Rack Calibration / Scaling | ||

| Ligne 44 : | Ligne 44 : | ||

|Random operation positions | |Random operation positions | ||

| | | | ||

| − | | | + | |All |

|- | |- | ||

|Grip positions for profiles | |Grip positions for profiles | ||

| Ligne 52 : | Ligne 52 : | ||

| | | | ||

| | | | ||

| − | | | + | |All except saw |

|- | |- | ||

|V notch blade vertical angle | |V notch blade vertical angle | ||

| Ligne 58 : | Ligne 58 : | ||

|v notches too deep or incorrect position | |v notches too deep or incorrect position | ||

| | | | ||

| − | | | + | |V Notching on ring |

|- | |- | ||

|Datum holes aligned with V notches | |Datum holes aligned with V notches | ||

| Ligne 64 : | Ligne 64 : | ||

|V notches incorrect but routing positions correct, or vice-versa | |V notches incorrect but routing positions correct, or vice-versa | ||

| | | | ||

| − | | | + | |All except saw |

|- | |- | ||

|Axis speeds (Pusher deceleration) | |Axis speeds (Pusher deceleration) | ||

| Ligne 70 : | Ligne 70 : | ||

|Random operation positions | |Random operation positions | ||

| | | | ||

| − | | | + | |Saw |

| + | |||

| + | Flowline | ||

| + | |||

| + | ZX3 / 4 | ||

|- | |- | ||

|Trimstart | |Trimstart | ||

Version actuelle datée du 2 avril 2020 à 16:25

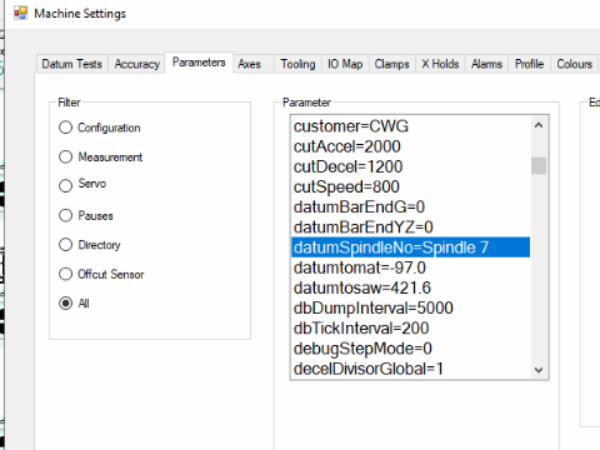

Software Settings that operators may have affect accuracy. How to reset to factory settings

Sommaire

| Software Setting | Description | Common Symptoms | Link to Page | Affected Machines |

|---|---|---|---|---|

| Fudged V and Y notch depths | Operator has changed software settings for V / Y notch depths without finding the root cause | V and Y notch depths inaccurate | All except Saw | |

| Kerf | Blade kerf incorrectly entered | Saw cuts correct for mitre cuts but not square cuts, or vice versa | All except ecoline | |

| Laser hole swarf | The laser hole is leaving swarf in the profile and creating a laser reading problem when the profile is pushed into the saw | Laser loading Errors

Random operation positions |

Flowlines, ZX3 / 4 with laser fitted | |

| Drive tuning - following error | X Axis or Saw pusher axis is not tuned correctly

Following error when reading laser position gives positional error |

Random operation positions, particularly on heavier profiles | All | |

| Rack Calibration / Scaling | Calibration has been altered incorrectly | Random operation positions | All | |

| Grip positions for profiles | Gripper position for a profile is causing it to tip

Gripper position is not firm enough causing gripper slip |

All except saw | ||

| V notch blade vertical angle | Tool angle of V notch blade is not accurately locating it in a vertical plane | v notches too deep or incorrect position | V Notching on ring | |

| Datum holes aligned with V notches | V notch offsets incorrect to datum position | V notches incorrect but routing positions correct, or vice-versa | All except saw | |

| Axis speeds (Pusher deceleration) | Pusher is not connected with end of profile after deceleration - ie pusher stopped but profile carried on | Random operation positions | Saw

Flowline ZX3 / 4 | |

| Trimstart | Trimstart is incorrectly set up or switched off, and the profile end is not square - ie the machine centre gripper has a different datum position to the saw pusher | Random operation positions on particular profiles | Flowlines, ZX3 / 4 without laser fitted |

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português