How to set up a gripper on a Flowline Mk3 with a Toothed Gripper

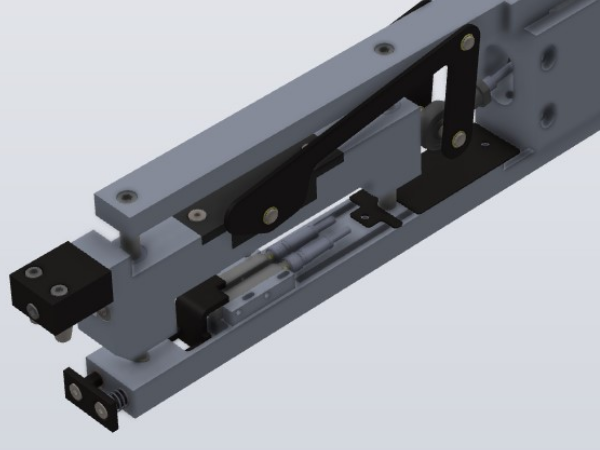

Mechanical Setup

This gripper design has two gripper switch inputs. This design was implemented to ensure the system can load a bar with an uneven or angled cut on the end. The sensors are activated by a long stroke on a spring, which has at least 10mm range of movement.

| Sensor | Function |

|---|---|

| Grip Min | Senses that a profile is gripped in the jaws. It should be active just after the spring is depressed |

| Grip Max | Activates when profile hits "end stop" of gripper mechanism whn loading. This ensures a reliable datum point. It should be active when the spring is fully depressed |

Software Process on Machining Centre side

| Step | Action | Notes |

|---|---|---|

| 1 | Move to loadingpos plus 5mm | |

| 2 | Wait for gripper max input | (completely bottom out gripper) |

| 3 | Wait for gripper to be within 0.25mm of expected position and 100ms to pass (to allow system to settle) | |

| 4 | Clutch and material load motor off | |

| 5 | Move to loadingpos | Pushes profile back to |

| 6 | Clutch on | holds profile steady |

| 7 | Wait for trim Pause | |

| 8 | Move x axis to loadingpos+200mm | Clear of tooling head |

| 9 | Run datum hole routine | |

| 10 | Move to loadingpos | |

| 11 | Grip | |

| 12 | Wait for grip on time | |

| 13 | Check that grip min switch is active | Ensure the bar is gripped |

| 14 | Grip lock on | Locks the gripper in its current position so it does not force the profile to "wheelie" |

Gripper Lock

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português