Setting V notch blade offsets on Ecoline winMulti Software

Sommaire

- 1 Introduction

- 2 Tutoriels prérequis

- 3 Étape 1 - Ensure the Datum and mitreOffset setup has been run

- 4 Étape 2 - Prepare Profiles

- 5 Étape 3 - Measure the bar width

- 6 Étape 4 - Separate the V notch to help measure

- 7 Étape 5 - Cut a V notch of around at a position of around 400mm

- 8 Étape 6 - Measure the depths

- 9 Étape 7 -

- 10 Commentaires

Introduction

This is the full setup procedure for V notches on an Ecoline. This should only be needed on initial commissioning or if the shape of the notch has changed due to some physical intervention, for example -

- Blade Change

- Blade buckled

- Tutoriels prérequis

Tutoriels prérequis

Étape 2 - Prepare Profiles

You will need several lengths of large outer frame, around 1m long with square end preps.

Étape 3 - Measure the bar width

Étape 4 - Separate the V notch to help measure

Starting with Front V notches (repeat this process later for rear V notches)

The distance between the V notch blades is known as the separation. This should be temporarily expanded during testing to make the shapes easier to measure.

It is normally around 136-138, so add 10mm on to the existing parameter to make 146-148

Étape 5 - Cut a V notch of around at a position of around 400mm

Use something around 30-40mm depth

Étape 6 - Measure the depths

The goal is to get both physical blade depths the same by tweaking the depth of the "outfeed" offset using the dOffsetVO.

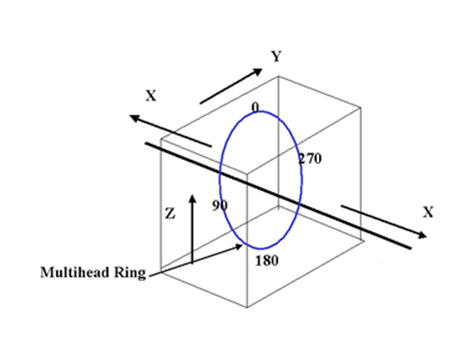

The notches are named "infeed" and "outfeed" to standardise the notch cut on both left and right feed machines

VI - Front Infeed

VO - Front Outfeed

WI - Rear Infeed

WO - Rear Outfeed

Make the adjustment and run again to check

Étape 7 -

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português