How to set up datum position on Ecoline

Introduction

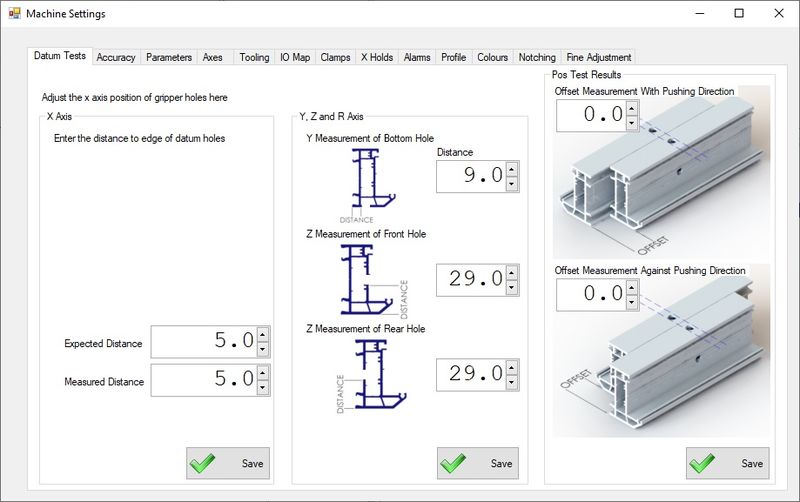

When an Ecoline is commissioned, the positional accuracy needs to be set up.

These are also useful tests to check if the machine is maintaining positional accuracy

Étape 1 - Run Datum Tests on Square-end profile

Run 3 tests on the same piece spaced apart by 20mm. Make sure the machine is reinitialised and redatums between each run.

This allows you to see if the position of the holes drifts along the bar

Aim to place the holes at least 400mm in from the bar end

See WinMulti - Datum Test for full instructions

End goal is to produce repeatable datum holes at the correct position from the end of the bar

Étape 2 - Run Datum Tests on Mitre End Profile

Run the tests again with a mitred end on the test pieces.

If the position is different to the square-end, the position can be adjusted with the parameter

ecoMitreAdjust

Étape 3 - Run Datum Tests on Arrow head End Profile

Run the tests again with arrowhead end on the test pieces.If the position is different to the square-end, the position can be adjusted with the parameter

ecoArrowAdjust

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português