Procedures for Daily, Weekly and monthly maintenance on Autoflow Outfeed Table

Introduction

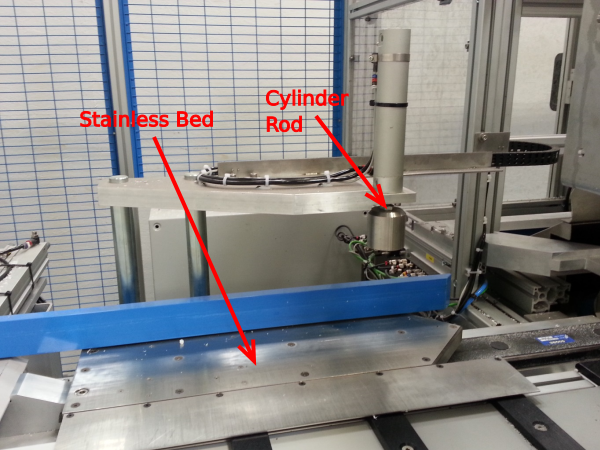

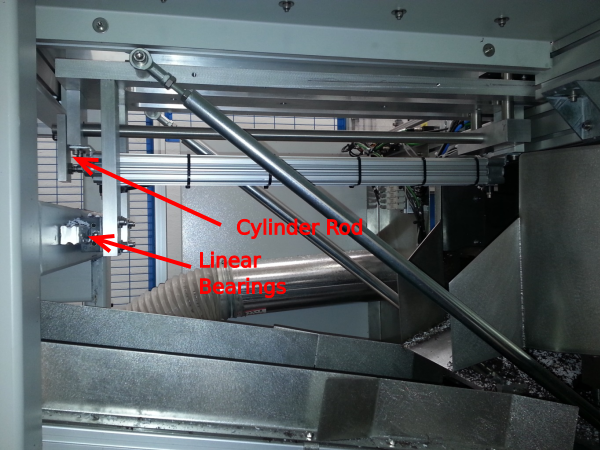

Étape 1 - Eject Bed

Daily – clean Stainless Steel Bed of swarf and remove any tape that may have transferred onto the bed during normal operation

Weekly – lightly oil shaft on underside of bed, lightly oil cylinder rod’s, lightly oil Hepco rail, 1 -2 pumps of grease into Linear Bearings, use a suitable foam cleaner for cleaning off the glue and tape residue left by the profile rolling along the beds

Monthly – check Hepco rail, Linear Bearings, Shafts and cylinders for damage or wear

Étape 2 - Outfeed Pushers and Safety Gate

Daily – Clean area of swarf and Debris

Weekly – Lightly oil Cylinder Rods, lightly oil Shafts, gently wipe over with a soft cloth the combined Klaxon and Strobe unit

Monthly – Check Cylinder Rods and Shafts for wear or damage, check Blue Bar for damage

Étape 3 - Conveyor Belt

Daily – Clean area of swarf and offcuts, empty waste bin as needed

Weekly – Check belt for signs of wear or cuts in belt

Étape 4 - Extraction System

Daily – check swarf level periodically throughout the shift and change the bag when full

Weekly – with the extraction system switched off tap / shake gently the White needle felt bag to allow the build-up of swarf on the inside of the bag to fall into the clear bag below

Monthly – visually check the White needle felt bags for any signs of damage/holes

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português