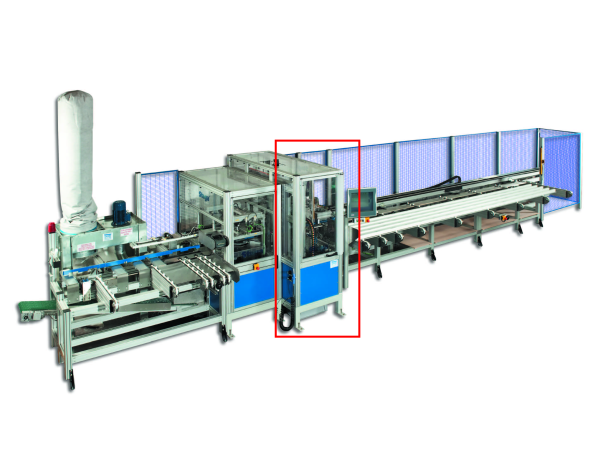

Procedures for Maintenance of the Autoflow Machining Centre Module

Sommaire

- 1 Introduction

- 2 Étape 1 - Infeed Clamp Vertical and horizontal rollers

- 3 Étape 2 - Spindle Motors

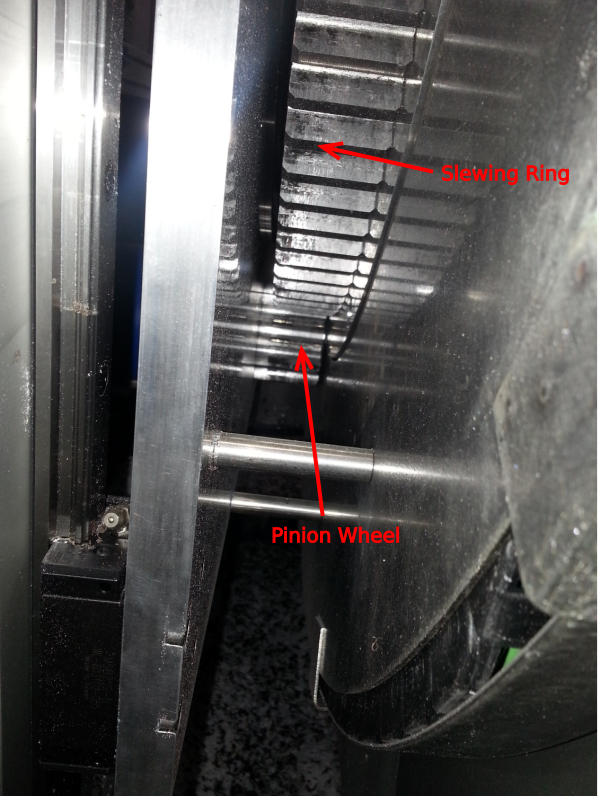

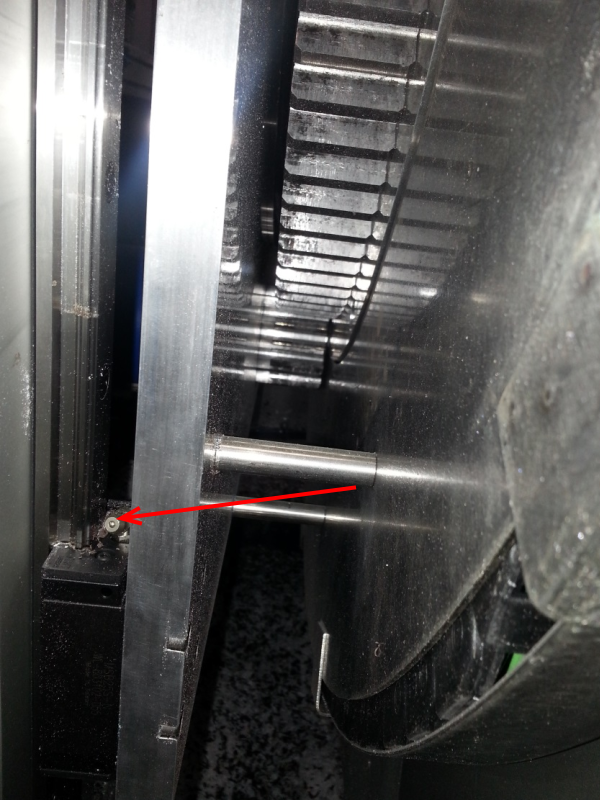

- 4 Étape 3 - Slewing Ring and Pinion wheel

- 5 Étape 4 - Y Axis Rails

- 6 Étape 5 - Outfeed Clamp Vertical and Horizontal Rollers

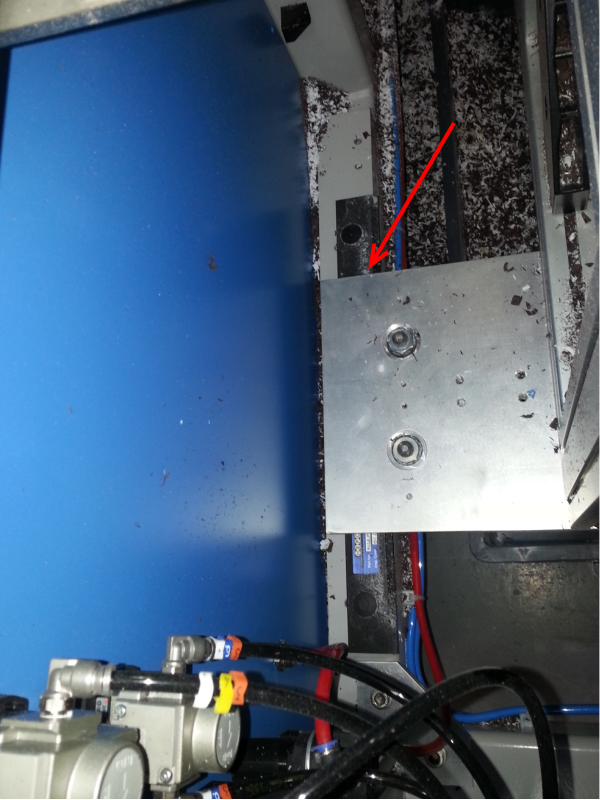

- 7 Étape 6 - Z Axis Linear Bearings

- 8 Étape 7 - Auto lube System

- 9 Commentaires

Introduction

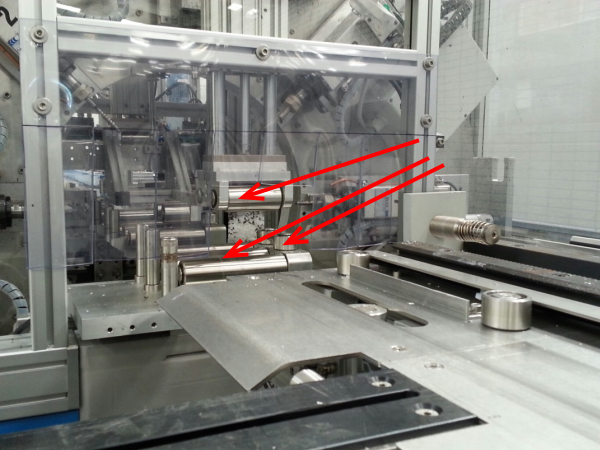

Étape 1 - Infeed Clamp Vertical and horizontal rollers

Daily – remove any tape or debris which may have become entangled in the rollers

Weekly – apply oil to top and side of roller units and then slowly spin them for a few revolutions to allow the oil to penetrate the bearings

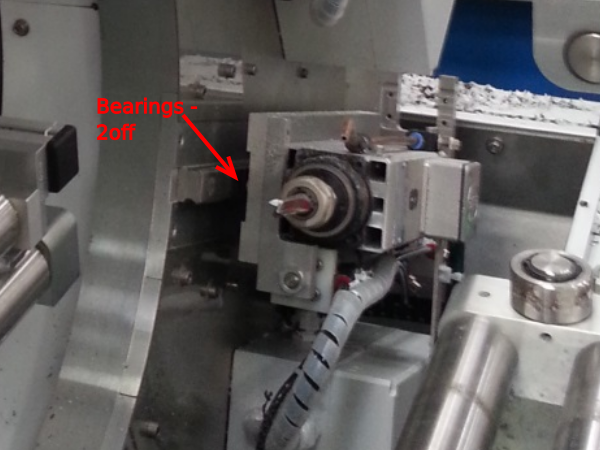

Étape 2 - Spindle Motors

Daily – Ensure that each spindle will turn freely with no grinding noise when rotating, check cutters for chips or damage, check V – Notch blades for chipped or damaged teeth

Check Spindles slide freely in and out on full range of movement

Monthly - Lubricate slideway bearings

Étape 3 - Slewing Ring and Pinion wheel

Daily – clean area of swarf or debris

Weekly – visually check pinion wheel and slewing ring for any damage, chips or cracks, remove any debris that may have become caught up in the teeth

Étape 4 - Y Axis Rails

4 off Located at the bottom of the machining centre cabinet.

Daily – clean away any debris

Monthly– lightly oil rail surface with supplied oil

Étape 5 - Outfeed Clamp Vertical and Horizontal Rollers

Daily – remove any tape or debris which may have become entangled in the rollers

Weekly – apply oil to top and side of roller units and then slowly spin them for a few revolutions to allow the oil to penetrate the bearings

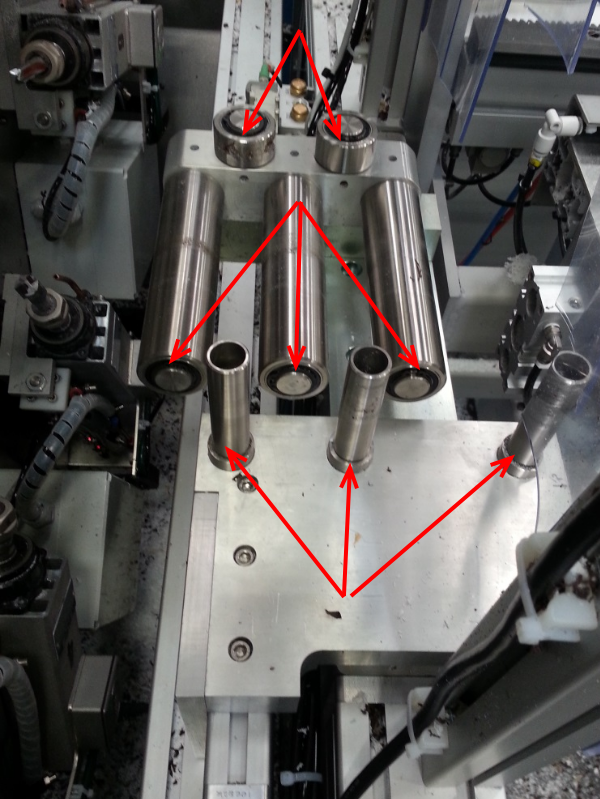

Étape 6 - Z Axis Linear Bearings

4 off

Daily – clear area of debris

Monthly– 1 – 2 pumps of grease via grease nipple, wipe away any excess grease

Étape 7 - Auto lube System

Check level of grease in Auto lube

Part replacement order code is M0001047

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português