Fitting the crank upgrade to Z065, Z066, Z067

Sommaire

- 1 Introduction

- 2 Étape 1 - Program Eaton Drives before they leave

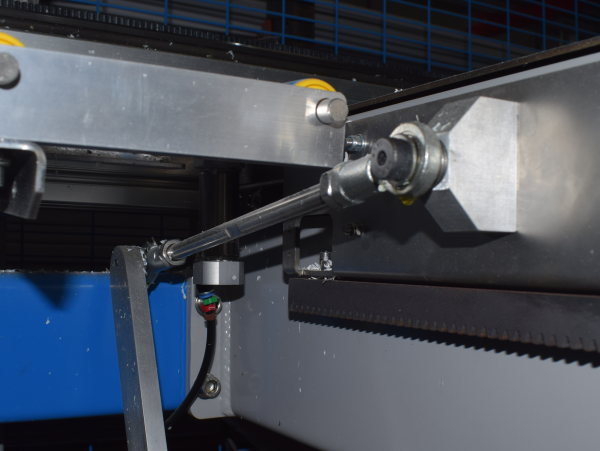

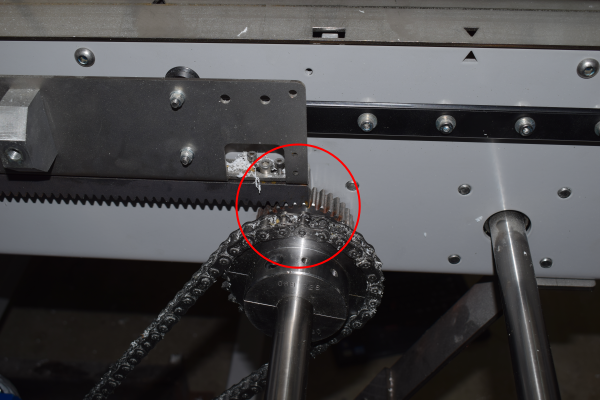

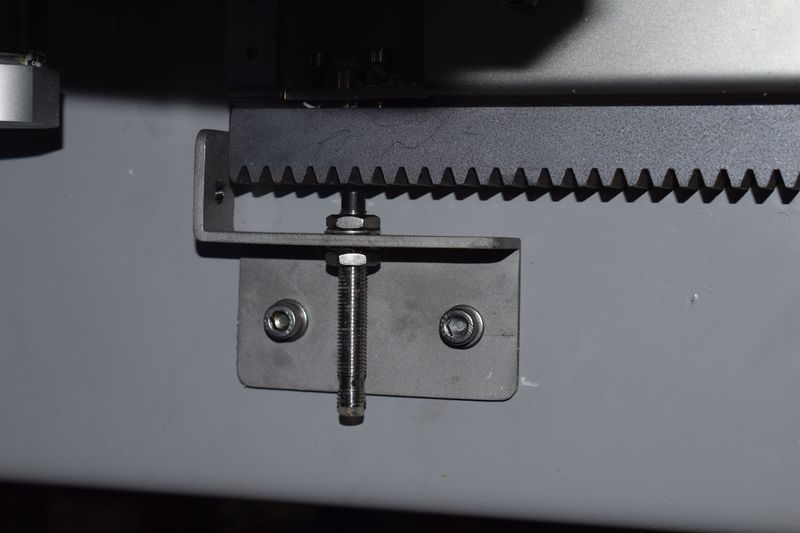

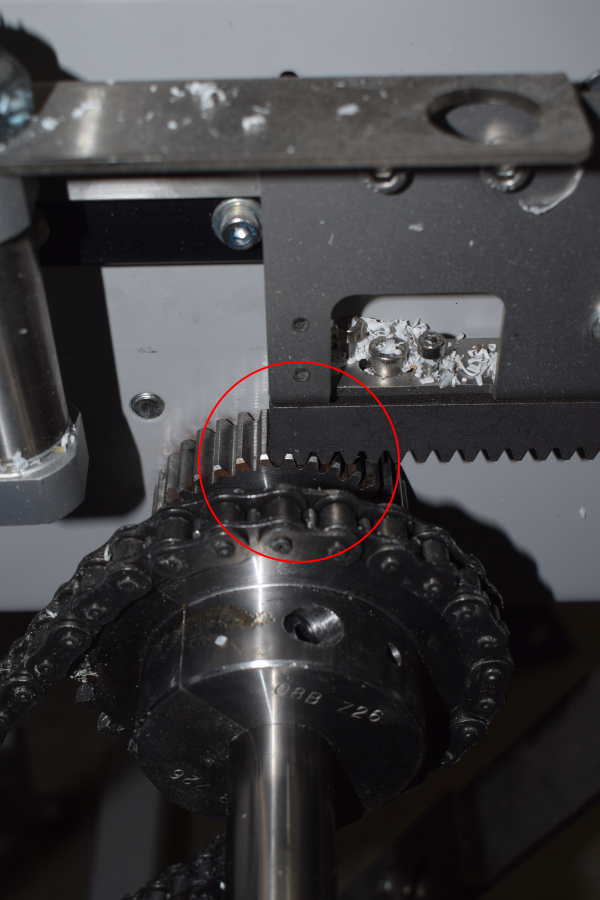

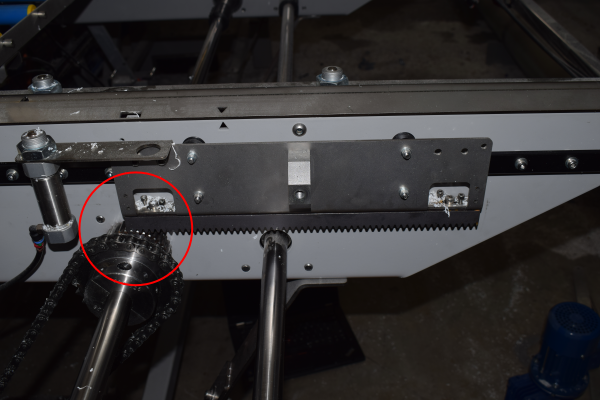

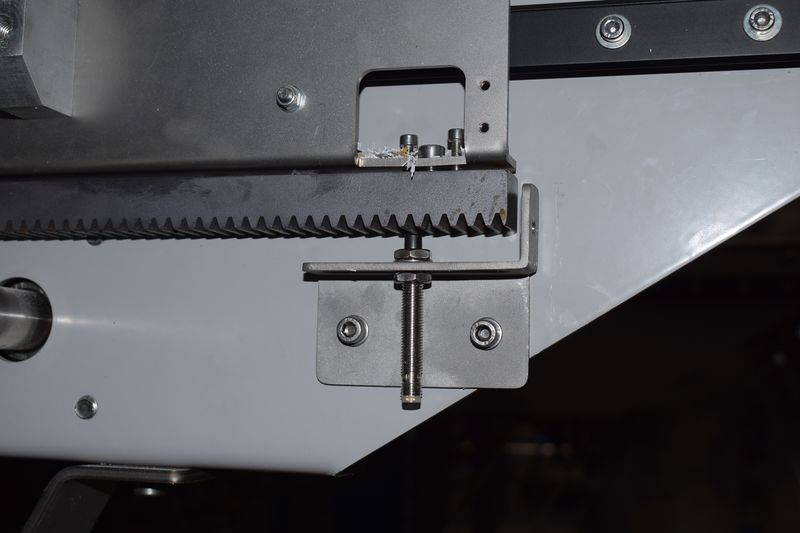

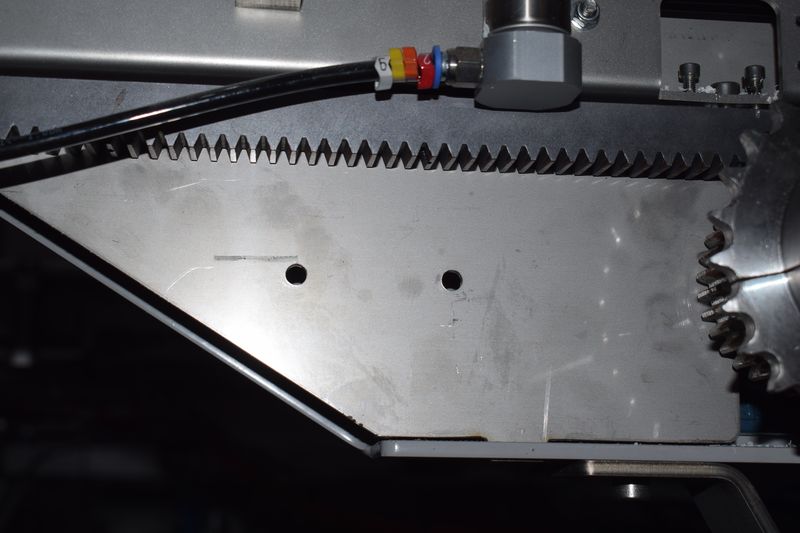

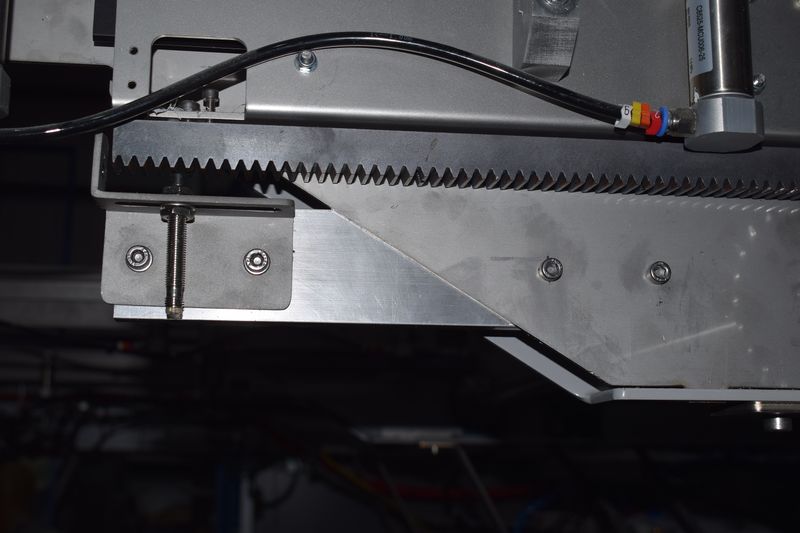

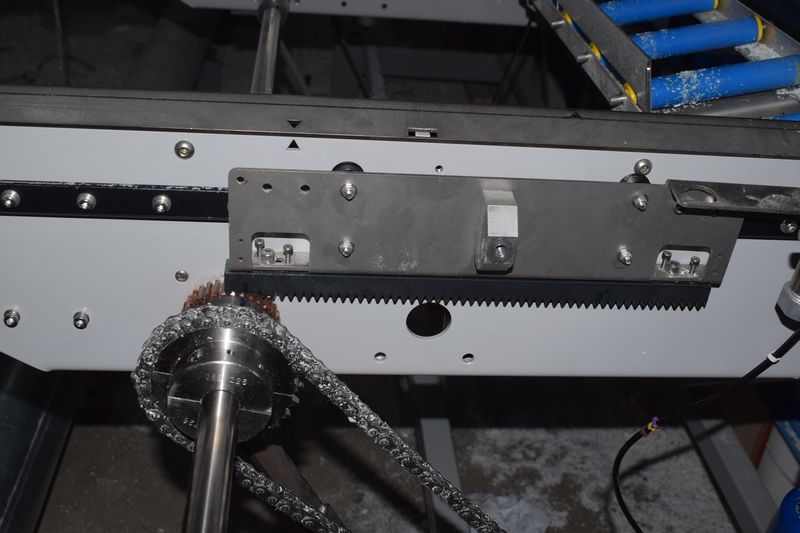

- 3 Étape 2 - Remove Link arm connecting to rack and pinion

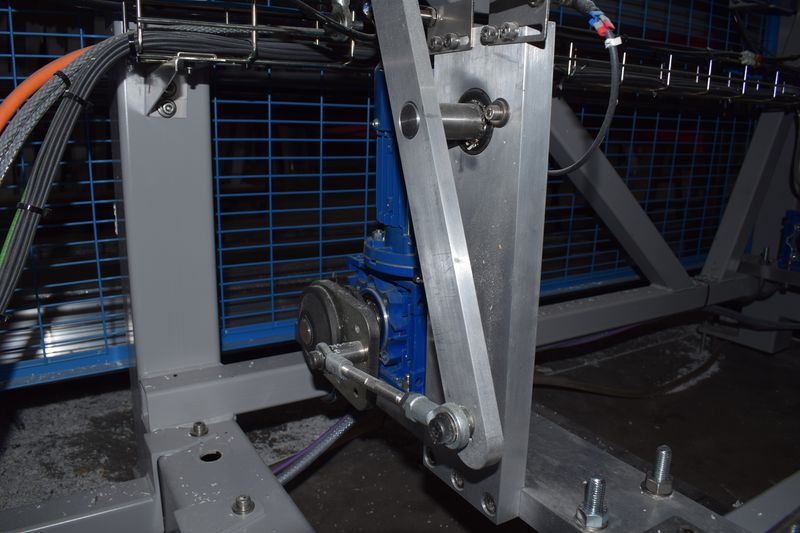

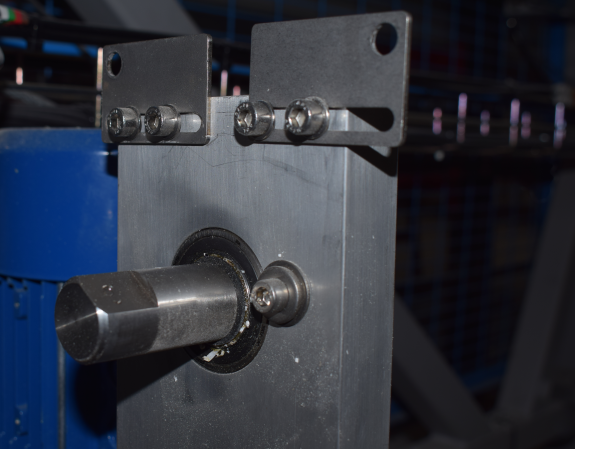

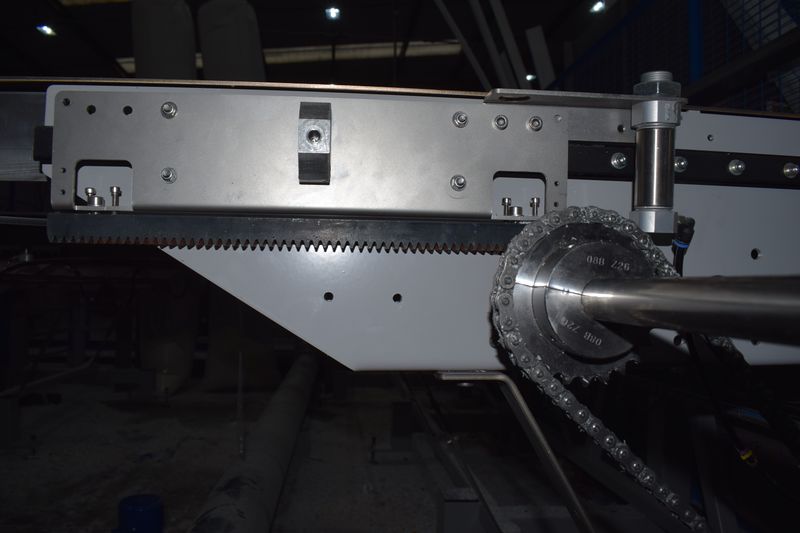

- 4 Étape 3 - Remove pivot shaft and arm

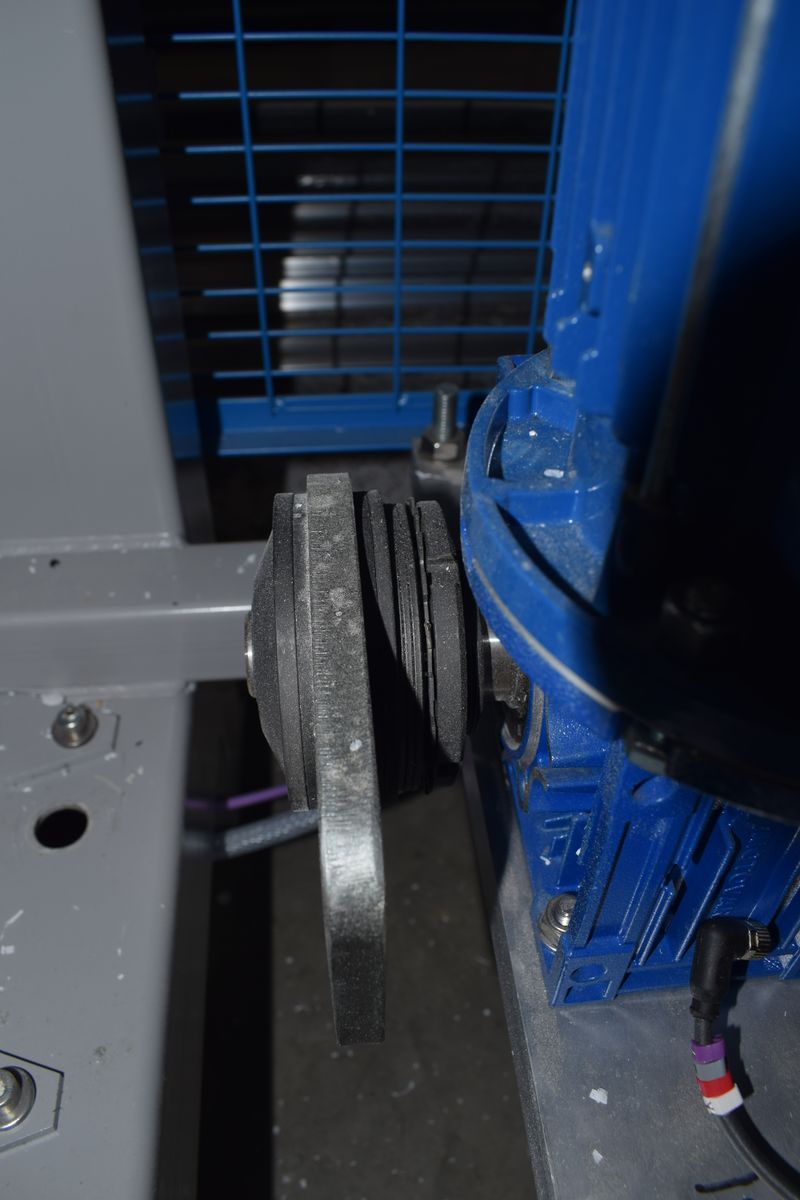

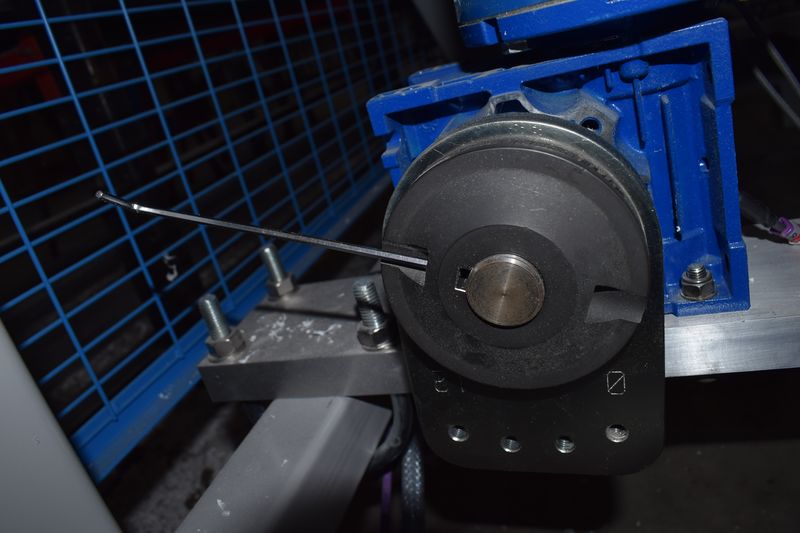

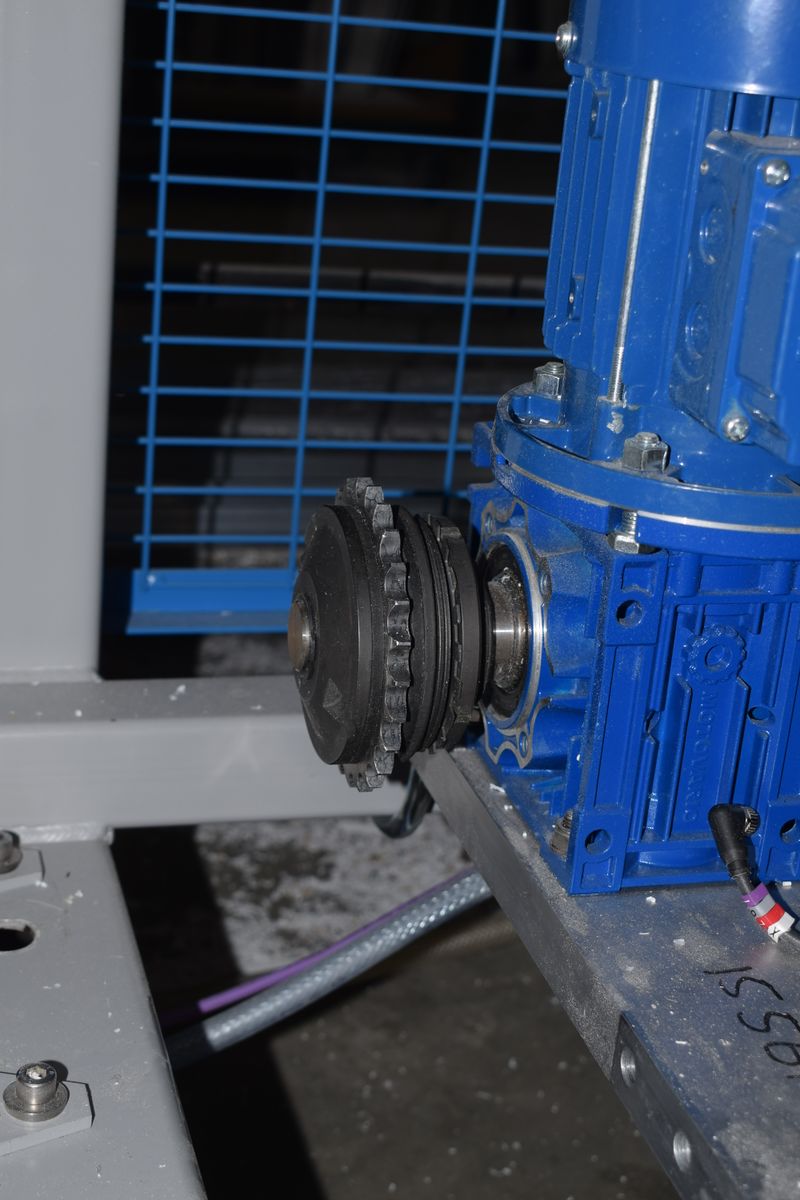

- 5 Étape 4 - Undo clutch and remove Cam

- 6 Étape 5 - Add sprocket to clutch

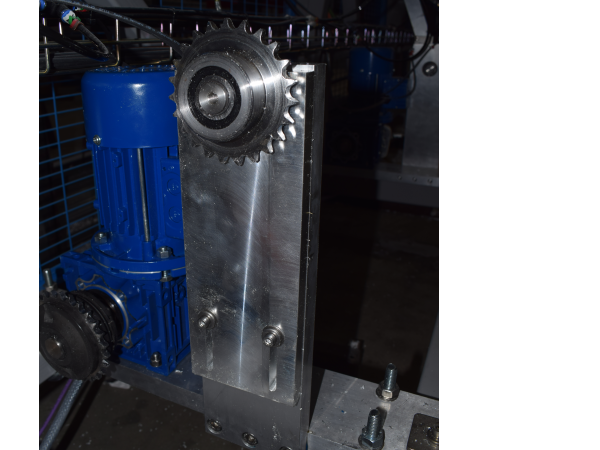

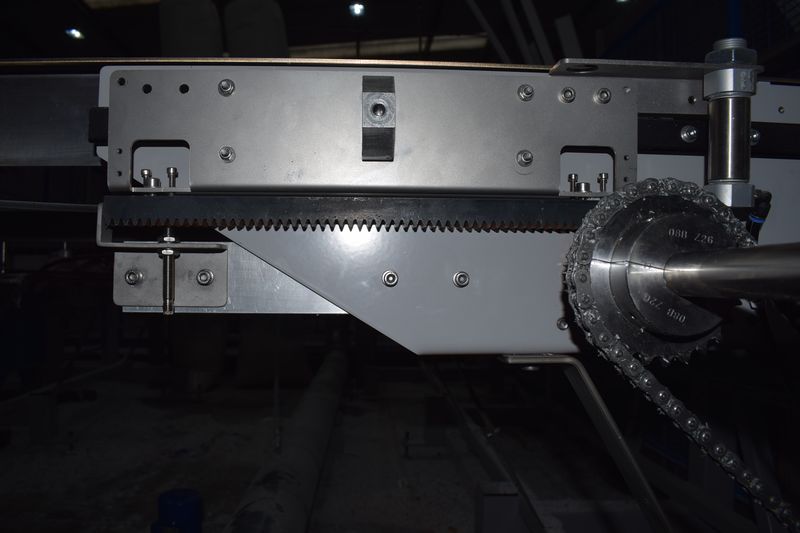

- 7 Étape 6 - Fix idler plate to upright

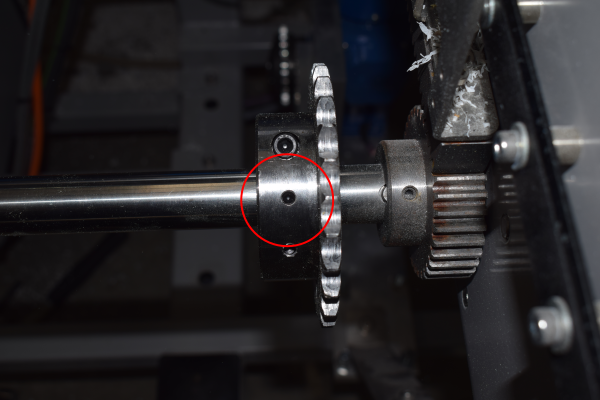

- 8 Étape 7 - Fix split sprocket onto drive shaft

- 9 Étape 8 - Drill and pin split sprocket to shaft

- 10 Étape 9 - Add chain minimum length sprocket to sprocket

- 11 Étape 10 - Fit Module C Crank Home sensor plate to Arm 5

- 12 Étape 11 - Fit Module C Crank Out sensor plate to Arm 5

- 13 Étape 12 - Fit Module D Crank Home sensor plate to Arm 5

- 14 Étape 13 - Fit Module D Crank Out sensor plate to Arm 5

- 15 Étape 14 - Fit Module E Crank Out sensor plate to Arm 5

- 16 Étape 15 - Fit Module E Crank Home sensor plate to Arm 5

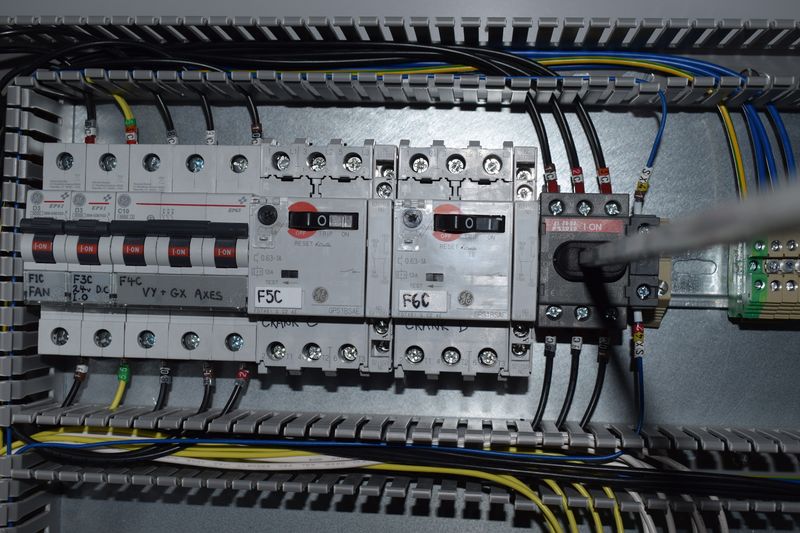

- 17 Étape 16 - Remove 2 off breaker and contactor Module C

- 18 Étape 17 - Add 2 off single pole breaker Module C

- 19 Étape 18 - Add 2 off Eaton Drive to Module C

- 20 Étape 19 - Add single pole breaker Module E

- 21 Étape 20 - Remove breaker and contactor Module E

- 22 Étape 21 - Add 1 Off Eaton drive to Module E

- 23 Étape 22 - For each Eaton Drive

- 24 Étape 23 - Wire Sensor Cables to EtherCAT boxes

- 25 Étape 24 - Latest Back End Software installed

- 26 Étape 25 - Map new Links

- 27 Étape 26 - Latest Front End software installed

- 28 Étape 27 - Test

- 29 Commentaires

Introduction

Étape 1 - Program Eaton Drives before they leave

Running frequency

Control mode

Accel time

Decel time

Étape 10 - Fit Module C Crank Home sensor plate to Arm 5

Sensor cables run to rear Module C cabinet - EtherCAT fieldbus boxes

Étape 11 - Fit Module C Crank Out sensor plate to Arm 5

This one has an extension that may or not be required. See Module D Crank Out Sensor for more info.

Sensor cables run to rear Module C cabinet - EtherCAT fieldbus boxes

Étape 12 - Fit Module D Crank Home sensor plate to Arm 5

Sensor cables run to rear Module C cabinet - EtherCAT fieldbus boxes

Étape 13 - Fit Module D Crank Out sensor plate to Arm 5

This one has an extension

Sensor cables run to rear Module C cabinet - EtherCAT fieldbus boxes

Étape 14 - Fit Module E Crank Out sensor plate to Arm 5

Sensor cables run to rear Module E cabinet - EtherCAT fieldbus boxes

Étape 15 - Fit Module E Crank Home sensor plate to Arm 5

This one has an extension

Sensor cables run to rear Module E cabinet - EtherCAT fieldbus boxes

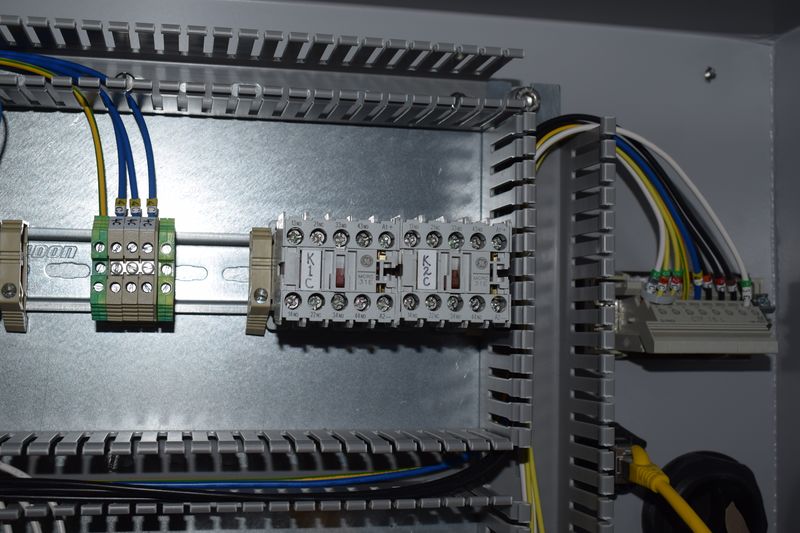

Étape 17 - Add 2 off single pole breaker Module C

Tidy wires away for the spare 2 phases

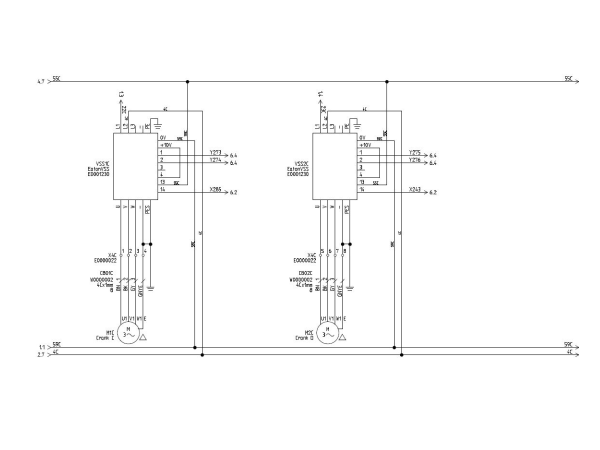

Étape 18 - Add 2 off Eaton Drive to Module C

May need to move trunking or mount directly to side of enclosure.

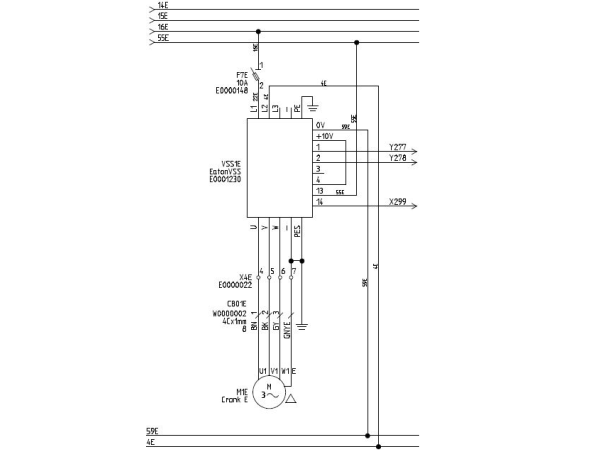

Étape 19 - Add single pole breaker Module E

Étape 20 - Remove breaker and contactor Module E

Étape 21 - Add 1 Off Eaton drive to Module E

Étape 22 - For each Eaton Drive

- 1 phase

- Neutral

- Earth

- Fwd and Reverse signals

- Wire motor cables directly to bottom of drives

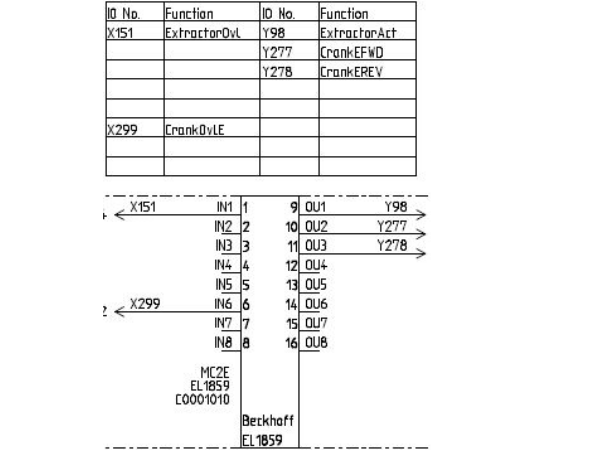

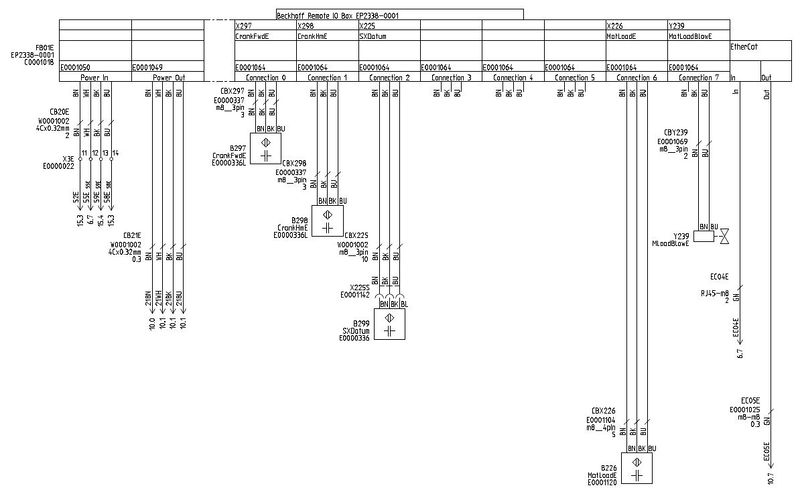

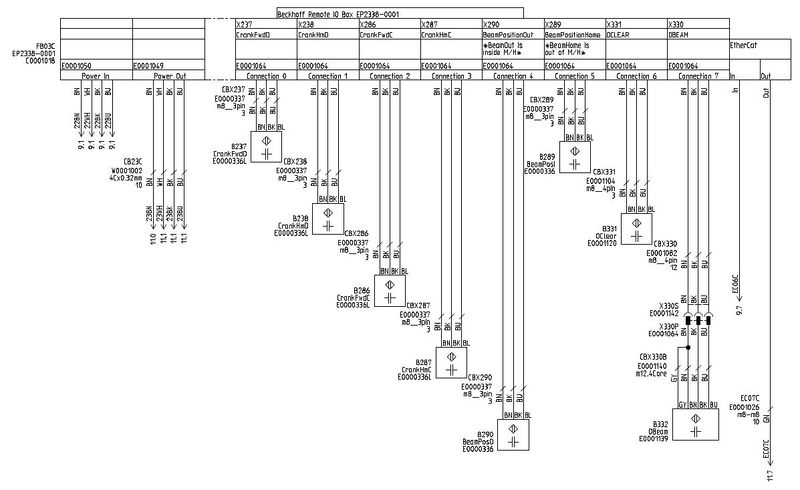

Étape 23 - Wire Sensor Cables to EtherCAT boxes

Module C and D cranks to back of Module C cabinet

Module E crank to back of Module E cabinet

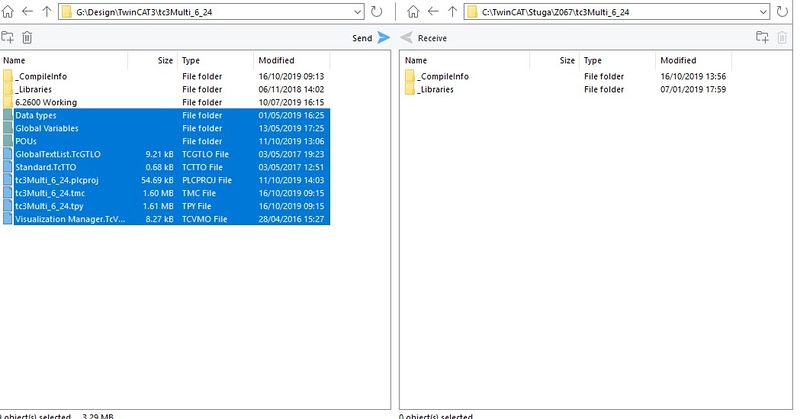

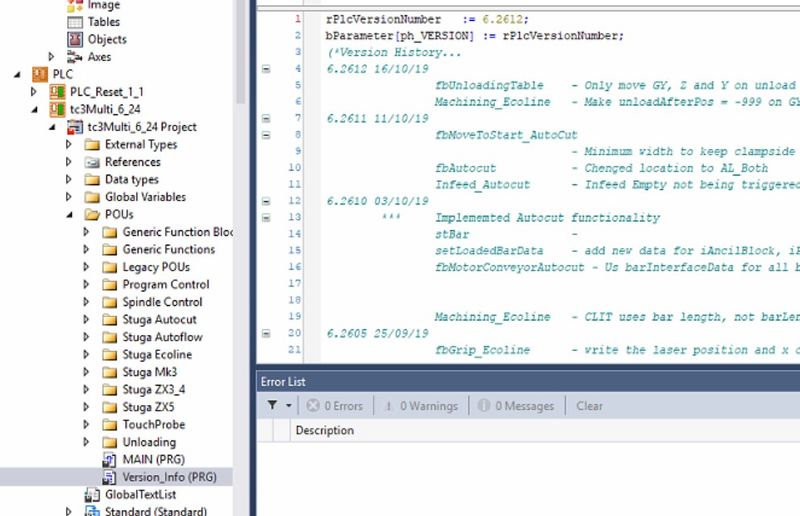

Étape 24 - Latest Back End Software installed

- Open Visual Studio

- Update from Target

- Save Solution as Archive with Bnn.yyyy.mm.dd

- Close VS

- Open File Transfer

- Local folder G:\Design\TwinCAT3\tc3Multi_6_24

- Remote Folder C:\TwinCAT\Stuga\Bnnn\tc3Multi_6_24

- In remote folder, delete all files and folders except _CompileInfo and _Libraries

- Send new folders (Data Types, Global Variables, POUs) and files below to remote

- Open VS and check if version number correct in Version_Info.txt

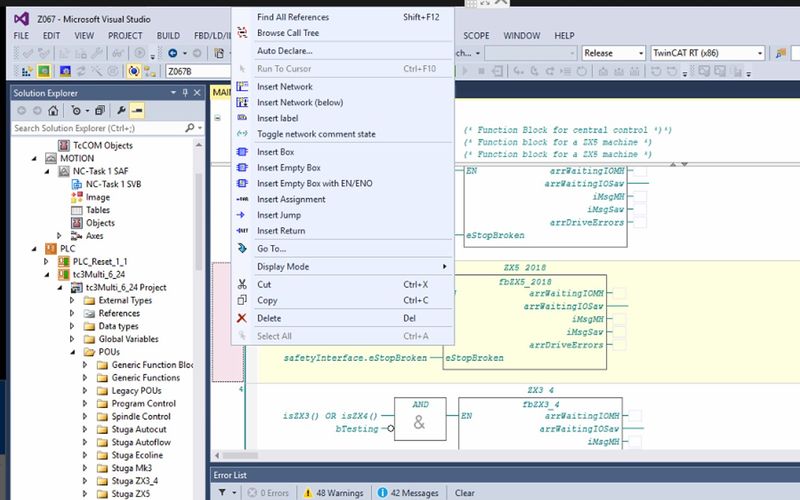

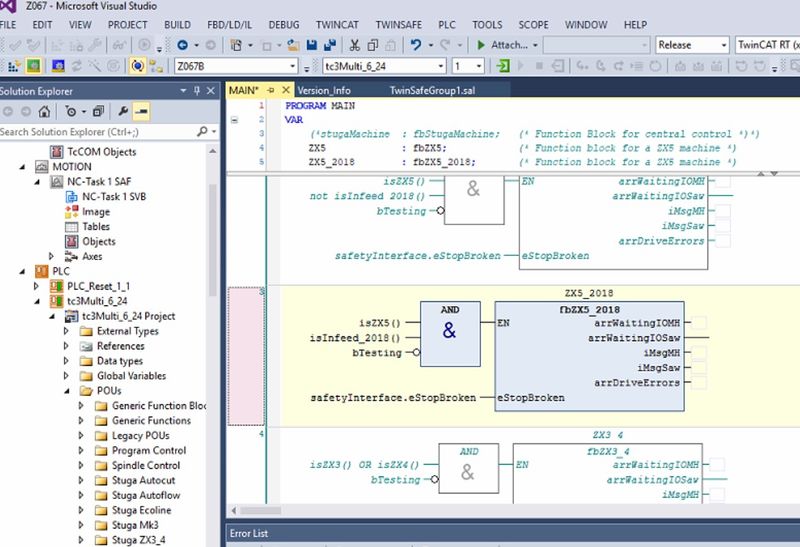

- Ensure the correct machine build is un-Remmed

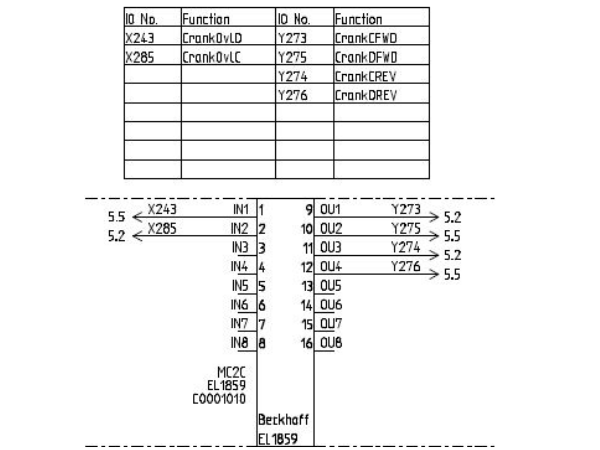

Étape 25 - Map new Links

| Output Ref | Name | EtherCAT Slice | Channel |

|---|---|---|---|

| 273 | Crank C Fwd | MC2C | 9 |

| 275 | Crank D Fwd | MC2C | 10 |

| 274 | Crank C Rev | MC2C | 11 |

| 276 | Crank D Rev | MC2C | 12 |

| 277 | Crank E Fwd | MC2E | 10 |

| 278 | Crank E Rev | MC2E | 11 |

Étape 26 - Latest Front End software installed

- Backup Old multi folder

- Copy in new winMulti version to c:\multi overwriting what is there

Étape 27 - Test

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português