A guide on how to fault find an emergency stop circuit fault on any Stuga machine.

Introduction

Étape 1 - Purpose of the Safety Circuit

A machinery safety circuit is designed to protect both the equipment and operators from harm by ensuring safe operation. It monitors critical safety functions, like emergency stops, protective guards, and sensors, to prevent accidents or malfunctions. In case of a failure or hazard detection, the circuit triggers shutdowns or alerts, ensuring that the machine operates within safe limits and reduces the risk of injury or damage.

Étape 2 - Different Types of Safety Circuits

Safety Relay Controllers: These are used to monitor safety devices like emergency stops, interlocks, and door switches. They ensure that the machine stops or enters a safe state when a fault or hazardous condition is detected. This is a hard-wired system using either a single or double channel loop and can have a feedback loop hard-wired into the system with a manual restart button. This system is the most commonly used in the Stuga machinery range.

Safety PLCs (Programmable Logic Controllers): These are specialised PLCs designed to handle safety applications. They provide high levels of safety and redundancy and can integrate both standard control tasks and safety control tasks in the same system, making them suitable for large, complex machinery. We have a number of machines that use a programmable safety system which is know as 'TwinSAFE' and is built into the Beckhoff EtherCAT system. These can be identified in the IO blocks of machine cabinets and have a yellow finish.

Other: There are lots of different types of safety circuit controllers that can be find on different machines. Some of these controllers are very basic and others are very complex.

Étape 3 - Identifying Different Circuits

Picture 1: This is a safety IO slice and is part of the Beckhoff TwinSAFE system.

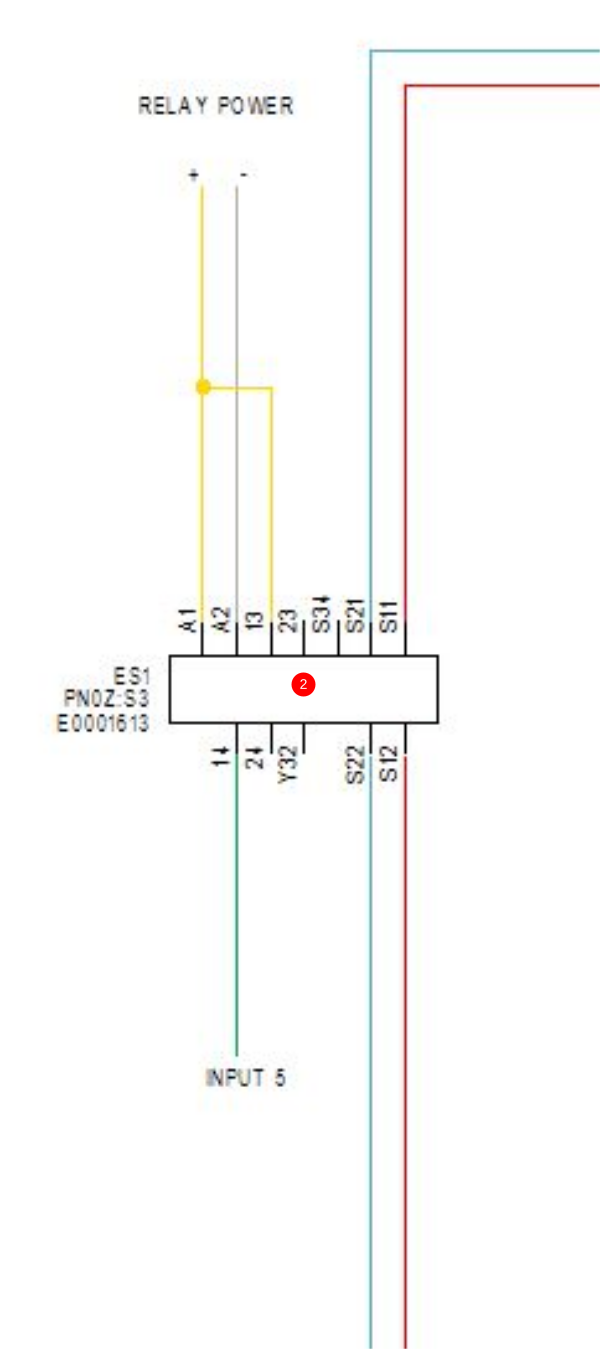

Picture 2: This is a safety relay which was used on Flowlines and Early ZX machines. This relay can be found in the Saw Infeed (Transfer) cabinet. This relay is typically wired as a single channel loop.

Picture 3: This is a safety relay which was used on Standalone Saws. This relay can be found in the main console electrical cabinet. This relay can vary in colour and some examples of this are blue and yellow. Again, this relay was typically used for a single channel loop. **PICTURES REQUIRED**

Picture 4: This is a safety relay which was introduced on Autoflow 2 machines and then used on ZX5's. This relay can typically be found in the Infeed cabinet on either machine. It is yellow in appearance which makes it prominent inside the cabinet. This relay is used for dual channel loops. **PICTURE REQUIRED**

Picture 5: This is a safety relay which was introduced on later ZX5 machines and now used in all applications from new builds to refurbs. This relay can typically be found in the Infeed cabinet. It is yellow in appearance which makes it prominent inside the cabinet. This relay is used for dual channel loops and provides additional diagnostics and settings on the unit front. **PICTURE REQUIRED**

Étape 4 - Principles of a 'Loop/ Channel'

**Do not use this section for theTwinSAFE system**

The fundamental wiring behind any single or dual channel safety relay is the 'e-stop loop'.

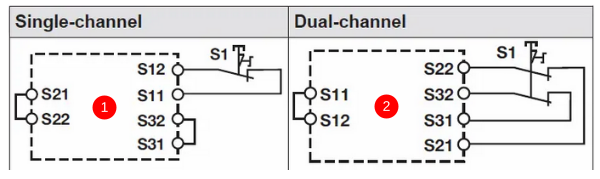

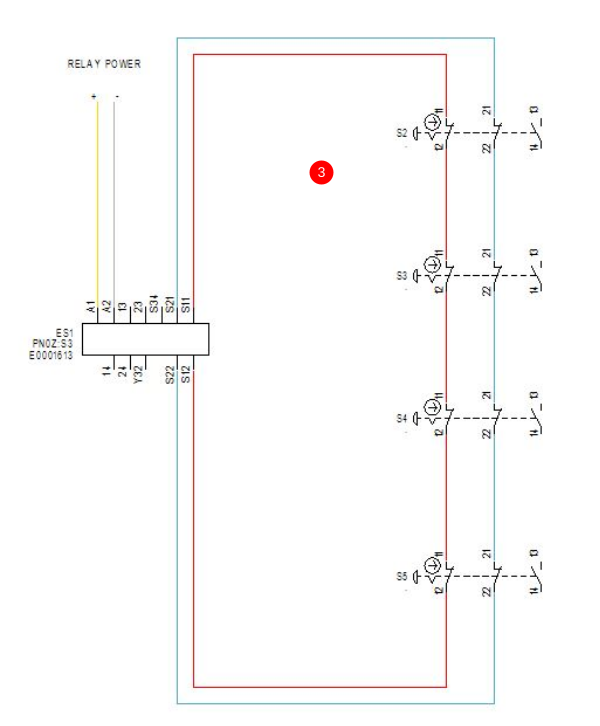

The 'e-stop loop' is a term used for the start and end of the safety circuit. Some systems have 1 loop (single channel) and some have 2 (dual channel). The 'loops' start and end at the safety relay. The most basic funtion of the safety relay is to send out a signal from one of its terminals and if it receives the same signal back on another terminal, it evaluates the circuit as safe. This can be seen in Picture 1. Picture 2 has the same principle, however, the safety relay is now evaluating 2 loops rather than 1. In both pictures, notice there is only 1 safety device connected. In this case, an emergency stop button. To add additonal safety devices, they are simply wired in series before or after another safety device (see Picture 3). The red wires are channel 1 and the blue wires are channel 2. Also notice that the channels always go through Normally Closed (N/C) contacts on any safety device. 'Normally Closed' means that the contact is closed when the device is in its 'Inactive' position. For an emergeny stop button, this condition is when the button is NOT pressed. In a guardswitch, this position is when the key IS inside the switch etc. If you reference Picture 3, N/C contacts allow the signal from terminal S11 to go through all of the emergency stop buttons, and return into S12. The same applies to terminals S21 and S22. This is how the relay evaluates if the circuit is safe or unsafe. If any of the contacts on the emergency stop buttons opens, the signal will be broken and the relay will shut down.

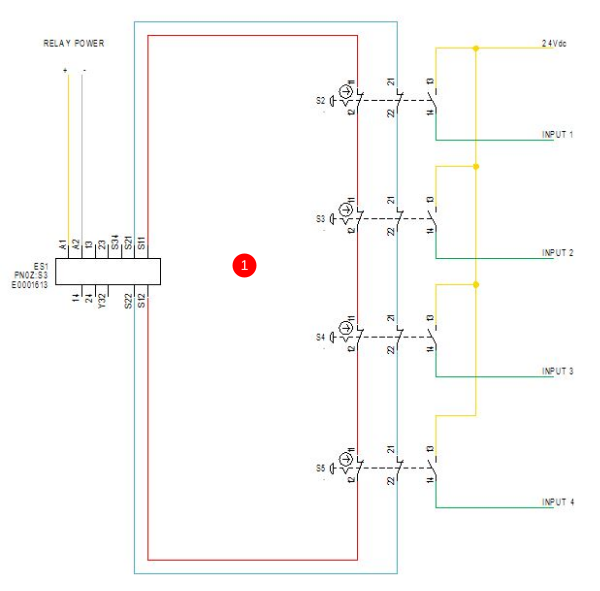

Étape 5 - Safety Status and IO

On newer Stuga machines, each safety device will have a feedback input to the PLC to let the user know which safety device is active. This input is not to be confused with the safety circuit itself. As you can see from Picture 1, we have the estop loops from the previous section but we now have an additional 24Vdc and Input across a Normally Open (N/O) contact on the same button. This contact works in the opposite way to the safety loop contacts. If you look at the symbol, you can see that when the button is in its 'Inactive' state, the 24Vdc line will not be able to pass through to the input. When the button is 'Active (pressed)' the 24Vdc will pass through to the input line and send a 24Vdc signal to the PLC signalling which button has been activated. This is the message that you will see on the user interface of the machine. It is also important to know that the safety relay also provides an input to the PLC to signal whether the safety relay is active (reset) or inactive (shut down). If the input is 'High' from the safety relay, the machine knows that the safety circuit is reset and the machine is safe to run. This can be seen in Picture 2.

Étape 6 - Relay Feedback Loop (Restart Circuit)

A key function of a safety relay is how it restarts after a shutdown. The function off the restart is determined by how safe the circuit needs to be. Some applications allow an automatic restart of the safety circuit which means as soon as the safety relay evaluates that the circuit is safe, it will automatically restart (reset). The safety circuits on Stuga machines (new and old) all use a manual restart with a reset pushbutton. On older machines (typically the ones that use a single channel circuit) the safety circuit is reset using only a reset button (see Picture 1). On newer machines (typically dual channel machines) use a reset button and also interlink with a N/C contact on 2 safety contactors (see Picture 2).

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português