Adding a secondary ultrasonic sensor to the 7 transfer loading positions to backup the flaps

Symptoms

- Bars bunch together on transfer table

- Bar will not unload from MH outfeed table for no reason

- Bar will not traverse across transfer table

Root Cause

If bars are bowed at one end, the transfer table flaps may not depress enough to activate the sensor. The sensor is limited to 4mm in its sensing range

Solution

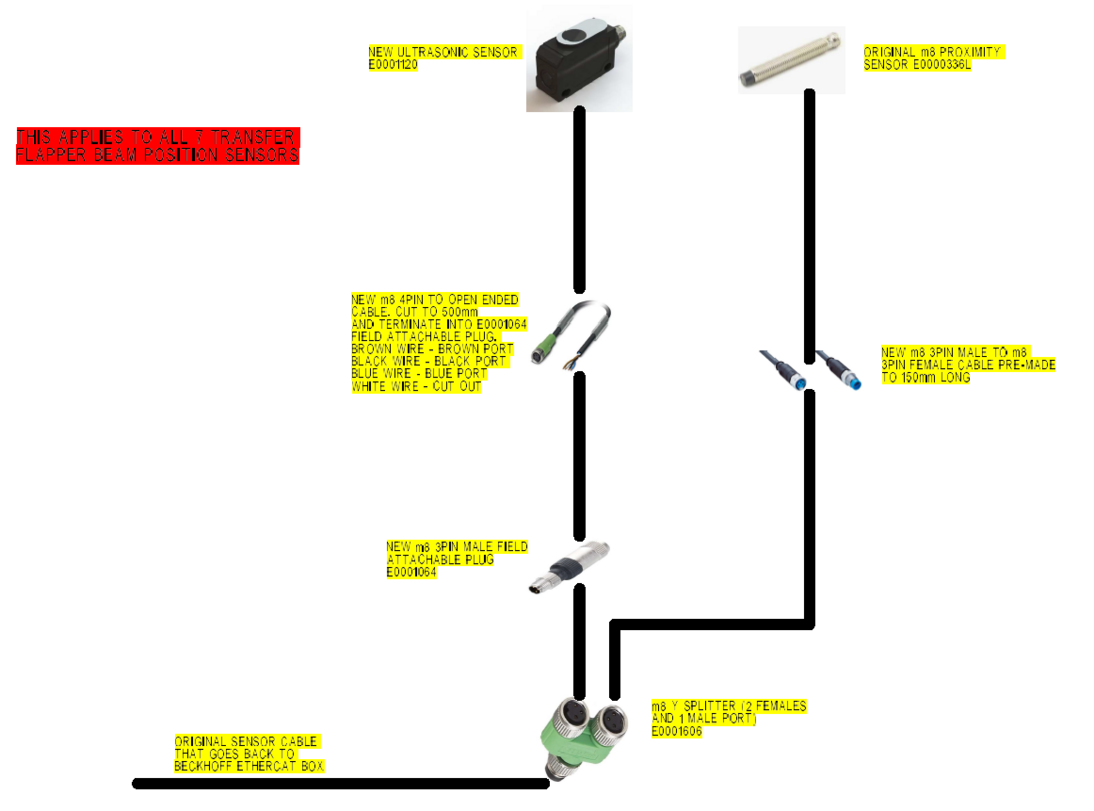

A simple-fit system has been designed to provide a secondary backup to the flap using an ultrasonic sensor and an M8 Tee Splitter. This is a plug and play solution that does not require any reprogramming or additional IO channels.

The kit comprises all the components to connect and fix an ultrasonic sensor to each flap

Wiring Diagram (one for each flap)

Installation

- The ultrasonic sensors will need teaching using the standard procedure Setting Ultrasonic Sensor - Horizontal

- The minimum sensing distance is 20mm, so the sensor brackets are designed to take the sensor lower than this

- The sensors should be angled to detect a profile in the normal "home" position, one sensor on its own will not be able to cover the full width of a slot.

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português