| [version en cours de rédaction] | [version en cours de rédaction] |

(Page créée avec « {{Tuto Details |Main_Picture=WinMulti_-_Datum_Test_Image.png |Main_Picture_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","ori... ») |

|||

| Ligne 18 : | Ligne 18 : | ||

{{Materials}} | {{Materials}} | ||

{{EPI}} | {{EPI}} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Prepare Square End Profile</translate> | ||

| + | |Step_Content=<translate>Cut 3 lengths of outerframe around 1000mm long{{Warning|...Make sure the gripper end of the profile has a clean edge - ie no swarf and profile tape is not "flapping" over the end}}<br /></translate> | ||

| + | }} | ||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate>Run Datum Tests on Square-end profile</translate> | |Step_Title=<translate>Run Datum Tests on Square-end profile</translate> | ||

| Ligne 28 : | Ligne 32 : | ||

See [[WinMulti - Datum Test]] for full instructions | See [[WinMulti - Datum Test]] for full instructions | ||

| − | End goal is to produce repeatable datum holes at the correct position from the end of the bar | + | End goal is to produce repeatable datum holes at the correct position from the end of the bar{{Info|...The position needs to be consistent and repeatable before you can proceed to next step}} |

| + | |||

<br />{{Idea|...If the datum position is not consistent, check laser beam cleanliness and laser focus}} | <br />{{Idea|...If the datum position is not consistent, check laser beam cleanliness and laser focus}} | ||

| Ligne 36 : | Ligne 41 : | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate> | + | |Step_Title=<translate>Check Gripper positions in Flowops Database</translate> |

| − | |Step_Content=<translate>{{ | + | |Step_Content=<translate>All gripper positions should be greater than 20 and less than 55</translate> |

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Choose 3 test profiles with different gripper positions</translate> | ||

| + | |Step_Content=<translate>Usually - | ||

| + | A - Slim Outer frame | ||

| + | |||

| + | B - Large Outer Frame | ||

| + | |||

| + | C - Door Profile | ||

| + | |||

| + | Cut \ / pieces around 1000mm | ||

| + | |||

| + | {{Warning|...Make sure the gripper end of the profile has a clean edge - ie no swarf and profile tape is not "flapping" over the end}}<br /></translate> | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Run datum tests on all 3 profiles</translate> | ||

| + | |Step_Content=<translate>{{Warning|...Do not attempt this if the square end datum positions are not consistent}}Run the test at the same position on all 3 profiles | ||

| + | <br /></translate> | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Check X position is the same on all 3 profiles</translate> | ||

| + | |Step_Content=<translate>If the position is varying, this highlights a gripping / measuring problem | ||

| − | + | Check | |

| − | + | * Laser focus and alignment | |

| − | ecoMitreAdjust</translate> | + | * G axis Datum position |

| + | * Y axis datum position | ||

| + | * Speed of infeed pull is steady and slow | ||

| + | * Gripper slipping (blunt) | ||

| + | {{Info|...The position needs to be identical before you can proceed to next step}}<br /></translate> | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate></translate> | ||

| + | |Step_Content=<translate></translate> | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate></translate> | ||

| + | |Step_Content=<translate></translate> | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Adjust Offset Parameter for mitres</translate> | ||

| + | |Step_Content=<translate>The position can be adjusted with the parameter | ||

| + | ecoMitreAdjust | ||

| + | After adjustment, run the tests again | ||

| + | {{Warning|...Only make an adjustment if you have consistent, repeatable results}}<br /></translate> | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate>Run Datum Tests on Arrow head End Profile</translate> | |Step_Title=<translate>Run Datum Tests on Arrow head End Profile</translate> | ||

| − | |Step_Content=<translate> | + | |Step_Content=<translate>Run the tests again with arrowhead end on the test pieces. |

If the position is different to the square-end, the position can be adjusted with the parameter | If the position is different to the square-end, the position can be adjusted with the parameter | ||

| Ligne 54 : | Ligne 100 : | ||

{{Notes}} | {{Notes}} | ||

{{PageLang | {{PageLang | ||

| + | |Language=en | ||

|SourceLanguage=none | |SourceLanguage=none | ||

|IsTranslation=0 | |IsTranslation=0 | ||

| − | |||

}} | }} | ||

{{Tuto Status | {{Tuto Status | ||

|Complete=Draft | |Complete=Draft | ||

}} | }} | ||

Version du 26 novembre 2020 à 11:45

How to set up datum position on Ecoline

Sommaire

- 1 Introduction

- 2 Étape 1 - Prepare Square End Profile

- 3 Étape 2 - Run Datum Tests on Square-end profile

- 4 Étape 3 - Check Gripper positions in Flowops Database

- 5 Étape 4 - Choose 3 test profiles with different gripper positions

- 6 Étape 5 - Run datum tests on all 3 profiles

- 7 Étape 6 - Check X position is the same on all 3 profiles

- 8 Étape 7 -

- 9 Étape 8 -

- 10 Étape 9 - Adjust Offset Parameter for mitres

- 11 Étape 10 - Run Datum Tests on Arrow head End Profile

- 12 Commentaires

Introduction

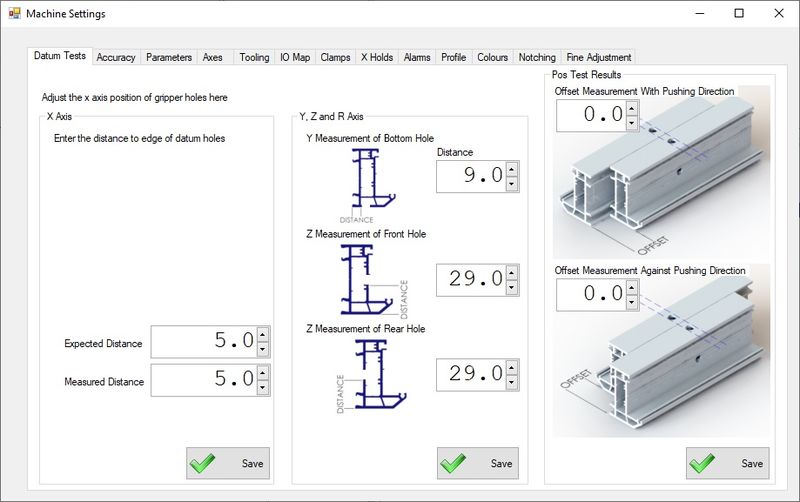

When an Ecoline is commissioned, the positional accuracy needs to be set up.

These are also useful tests to check if the machine is maintaining positional accuracy

Étape 1 - Prepare Square End Profile

Cut 3 lengths of outerframe around 1000mm longÉtape 2 - Run Datum Tests on Square-end profile

Run 3 tests on the same piece spaced apart by 20mm. Make sure the machine is reinitialised and redatums between each run.

This allows you to see if the position of the holes drifts along the bar

Aim to place the holes at least 400mm in from the bar end

See WinMulti - Datum Test for full instructions

End goal is to produce repeatable datum holes at the correct position from the end of the bar

Étape 3 - Check Gripper positions in Flowops Database

All gripper positions should be greater than 20 and less than 55

Étape 4 - Choose 3 test profiles with different gripper positions

Usually -

A - Slim Outer frame

B - Large Outer Frame

C - Door Profile

Cut \ / pieces around 1000mm

Étape 5 - Run datum tests on all 3 profiles

Run the test at the same position on all 3 profiles

Étape 6 - Check X position is the same on all 3 profiles

If the position is varying, this highlights a gripping / measuring problem

Check

- Laser focus and alignment

- G axis Datum position

- Y axis datum position

- Speed of infeed pull is steady and slow

- Gripper slipping (blunt)

Étape 7 -

Étape 8 -

Étape 9 - Adjust Offset Parameter for mitres

The position can be adjusted with the parameter

ecoMitreAdjust

After adjustment, run the tests again

Étape 10 - Run Datum Tests on Arrow head End Profile

Run the tests again with arrowhead end on the test pieces.

If the position is different to the square-end, the position can be adjusted with the parameter

ecoArrowAdjust

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português