| [version en relecture] | [version en relecture] |

| Ligne 76 : | Ligne 76 : | ||

The File will basically have as many Positions in as Needed and they are all different and from time to time need Checking. | The File will basically have as many Positions in as Needed and they are all different and from time to time need Checking. | ||

| − | Very important to make sure each range, so for example an Offcut between 1650 and 1900 is going to be Ejected at a position of 2550 on the X axis, So the Shortest Offcut in this range must be Able to cover the Outfeed Clear,Flappers and Saw Material Load sensor | + | Very important to make sure each range, so for example an Offcut between 1650 and 1900 is going to be Ejected at a position of 2550 on the X axis, So the Shortest Offcut in this range must be Able to cover the Outfeed Clear,Flappers and Saw Material Load sensor And still Be Balanced Well enough not to Fall off or go at an angle when Pushed across the Table or when The Saw goes to Lift/Slide or Lift/Load it across. |

| − | We do things slightly different at the end of the file for the Maximum Lengths, | + | <u>'''We do things slightly different at the end of the file for the Maximum Lengths,'''</u> |

| Ligne 93 : | Ligne 93 : | ||

| + | {{Idea|THE MAXIMUM POSITION ON Multihead X axis is the X axis position with Grip Push Activated and about 10mm Fwd of the End Beam.}} | ||

| − | + | <br />{{Idea|1=THE MAXIMUM POSITION ON Saw Pusher axis is DatumToMat position just behind End Beam, Then Disable Pusher and Push until against End Position Damper and Record its position. | |

So if Maximum Saw Pusher is 7350 then SawLoadDiff is Saw Pusher Maximum 7350 - Maximum X position 7110 = -250}}<br /> | So if Maximum Saw Pusher is 7350 then SawLoadDiff is Saw Pusher Maximum 7350 - Maximum X position 7110 = -250}}<br /> | ||

| − | |||

| − | |||

Flowline SawLoadDif is normally set approx 0 to 20mm | Flowline SawLoadDif is normally set approx 0 to 20mm | ||

| Ligne 108 : | Ligne 107 : | ||

'''You can add new Positions, Amend or delete the Sloadpos.saw file as needed if a Certain Offcut size is not balanced.''' | '''You can add new Positions, Amend or delete the Sloadpos.saw file as needed if a Certain Offcut size is not balanced.''' | ||

| − | '''Another Point is the Grip Push Speed and How long the timeout is for, Very Important to have the Correct Amount of time for the push so it doesn't catch on end of saw Pusher.''' | + | '''Another Point is the Grip Push Speed and How long the timeout is for, it is Very Important to have the Correct Amount of time for the push so it doesn't catch on end of saw Pusher.''' |

| + | |||

'''Try and Aim for Grip Push Extend Speed on cylinder of about 2 seconds and set the Pause "grippushout=2500"'''</translate> | '''Try and Aim for Grip Push Extend Speed on cylinder of about 2 seconds and set the Pause "grippushout=2500"'''</translate> | ||

Version du 30 mars 2020 à 12:13

Understanding What Sloadpos is and what the 3 column values mean on Flowline,ZX3 and ZX4. The ZX5, Autoflow and Microline do not use system in the same manner described here.

Sommaire

- The Sloadpos.saw file meaning is short for Sharing Load positions.

- To use the file in sparams.saw unsure shareLoadPos=1.

- The files on Flowline,ZX3 or ZX4 are normally found in the Saw folder, however if its All in One software it is DDRIVE folder.

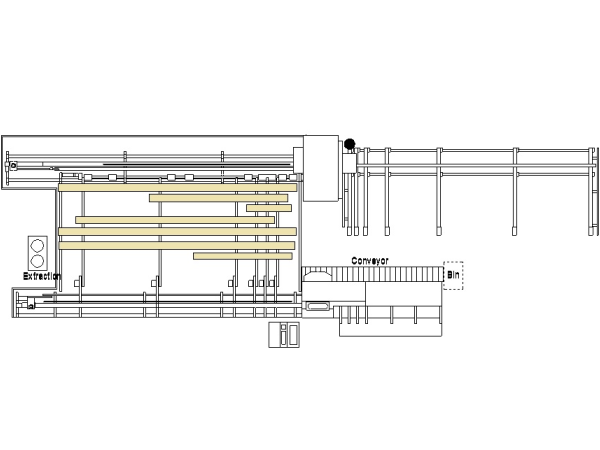

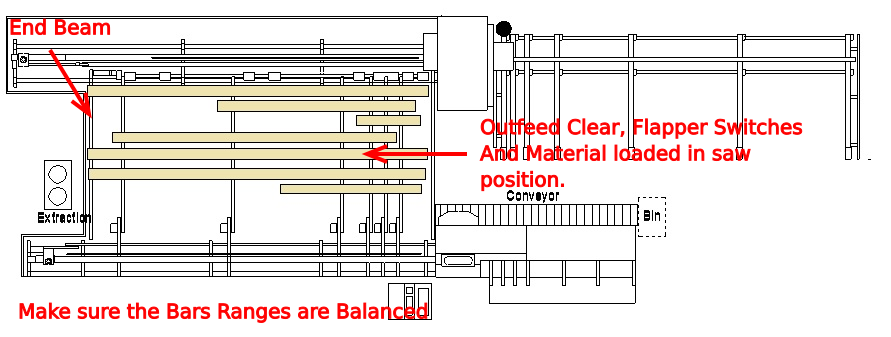

The Main Purpose of the file is To eject New Bar lengths and offcuts into a safe Balanced position on the Transfer table. The Main Rules Are:

- Set the Maximum Position the Multihead can goto without stalling the X axis.

- Check the SawLoadDiff also works for Maximum Position.

- Check the SawLoadDiff Gives Clearance for the end of Bar getting Lifted accross.

- The Offcut must always be Balanced .

- The End of the offcut must always

- Cover the Outfeed Clear Sensor.

- Transfer Table Flappers.

- Material Loaded sensor on saw.

- Ensure the Safe Position after Unload is always between Telescopic Pushers.

The sloadpos.saw file consists of 3 Columns .

- The 1st Column is the Size of the Bar/Offcut.

- The 2nd Column is the X axis unload position for that Range of Offcut.

- The 3rd Column is the Safe position after Unload, It MUST always be Bigger than the 2nd Column as well as In between Telescopic Pushers.

Here is an example of how it works.

0,1600,2400

700,1750,2400

1200,2160,2400

1650,2550,3700

1900,2650,3700

2100,2850,3700

2300,3050,3700

2500,3700,4900

3100,3900,4900

3300,4100,4900

3500,4300,4900

3700,4500,4900

3900,4700,4900

The File will basically have as many Positions in as Needed and they are all different and from time to time need Checking.

Very important to make sure each range, so for example an Offcut between 1650 and 1900 is going to be Ejected at a position of 2550 on the X axis, So the Shortest Offcut in this range must be Able to cover the Outfeed Clear,Flappers and Saw Material Load sensor And still Be Balanced Well enough not to Fall off or go at an angle when Pushed across the Table or when The Saw goes to Lift/Slide or Lift/Load it across.

We do things slightly different at the end of the file for the Maximum Lengths,

5800,6450,7120

5900,L620,7120

6480,7110,7120

Flowline SawLoadDif is normally set approx 0 to 20mm

Zx3 and Zx4 SawLoadDif is normally -570 to -650 approx.

You can add new Positions, Amend or delete the Sloadpos.saw file as needed if a Certain Offcut size is not balanced.

Another Point is the Grip Push Speed and How long the timeout is for, it is Very Important to have the Correct Amount of time for the push so it doesn't catch on end of saw Pusher.

Try and Aim for Grip Push Extend Speed on cylinder of about 2 seconds and set the Pause "grippushout=2500"

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português