| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 82 : | Ligne 82 : | ||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate>Removal of Components (Saw Console)</translate> | |Step_Title=<translate>Removal of Components (Saw Console)</translate> | ||

| − | |Step_Content=<translate></translate> | + | |Step_Content=<translate>List of components to be removed and unwired from the Saw console cabinet: |

| + | |||

| + | <br /> | ||

| + | |||

| + | * AcePC - ''Remove the PC and any wiring that is NOT on a 12 core cable that goes across to the Saw module. The wires that are part of a multicore cable need to be unwired ready for installation into the new IO slices.'' | ||

| + | * Nextmove ESB - Remove unit and wiring. | ||

| + | * Samsung servo drive - Remove unit and wiring. | ||

| + | * Baldor servo drive - Remove unit and wiring. | ||

| + | * Single pole 10A breaker - Remove wiring and take breaker out. | ||

| + | * Interface relays - All outputs will be +24Vdc switching. If valve bank polarity is incorrect, use an attached TB from Stuga. | ||

| + | * Serial cable for printer - ''The printer will now run on EtherNET straight from MH cabinet.'' | ||

| + | |||

| + | The servo drive cables can be removed at this stage. Cut them in half in the Transfer cabinet and pull the remainder through the conduit.</translate> | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate>Removal of Components (Transfer Cabinet)</translate> | |Step_Title=<translate>Removal of Components (Transfer Cabinet)</translate> | ||

| − | |Step_Content=<translate></translate> | + | |Step_Content=<translate>List of components to remove from the Transfer cabinet: |

| + | |||

| + | <br /> | ||

| + | |||

| + | * BandR PLC - ''Remove the unit but keep the wiring for the new IO slices.'' | ||

| + | * Omron PLC - ''Remove the unit but keep the wiring for the new IO slices.'' | ||

| + | * Interface Relays - ''Interface relays no longer needed so relays that interface 'saw and transfer' and 'transfer and multi' can be removed.''</translate> | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| Ligne 98 : | Ligne 116 : | ||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate>Removal of Components (General)</translate> | |Step_Title=<translate>Removal of Components (General)</translate> | ||

| − | |Step_Content=<translate> | + | |Step_Content=<translate>List of general components to be removed: |

| + | |||

| + | <br /> | ||

| + | |||

| + | * Monitor on MH side - ''This will be replaced with a touchscreen.'' | ||

| + | * Monitor on Saw side - ''This will be replaced with a screen (not touch).'' | ||

| + | * Keyboard from Saw side ''- This will be replaced with a bluetooth keyboard.'' | ||

| + | * Keyboard from MH side - ''This will be replaced with a keyboard and mouse combination.'' | ||

| + | * Mouse from MH side - ''Remove mouse. Will now be integrated into keyboard.'' | ||

| + | |||

| + | <br /></translate> | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

Version du 18 novembre 2019 à 17:39

On site upgrade of Flowline Mk3 with Beckhoff AX8000 drives, EtherCAT IO slices and TwinCAT 3 IPC.

Sommaire

- 1 Introduction

- 2 Étape 1 - Familiarisation

- 3 Étape 2 - Parts Identification and Rectification

- 4 Étape 3 - Health and Safety

- 5 Étape 4 - Removal of Components (MH Cabinet)

- 6 Étape 5 - Removal of Components (Saw Console)

- 7 Étape 6 - Removal of Components (Transfer Cabinet)

- 8 Étape 7 - Removal of Components (Cabling)

- 9 Étape 8 - Removal of Components (Motors and Gearboxes)

- 10 Étape 9 - Removal of Components (General)

- 11 Étape 10 - Preparation for New Components (MH Side)

- 12 Étape 11 - Preperation for New Components (Saw Side)

- 13 Étape 12 - Adding New Components (MH Cabinet)

- 14 Étape 13 - Adding New Components (Saw Console)

- 15 Étape 14 - Adding New Components (Transfer Cabinet)

- 16 Étape 15 - Adding New Components (Motors and Gearboxes)

- 17 Étape 16 - Adding New Components (General)

- 18 Étape 17 - Adding Offcut Measuring*

- 19 Étape 18 - Adding Zero Speed Detector*

- 20 Commentaires

Introduction

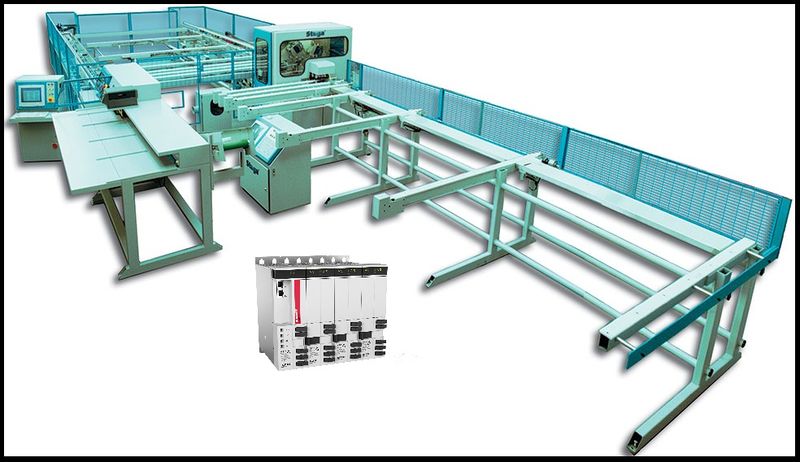

The Flowline Mk3 is a Stuga built and designed machine for prepping and cutting uPVC windows and doors. The Flowline is the first machine of the Stuga 'U' shaped machines which has prepping and cutting working in the same machine package. The Flowline is still a fantastic machine for the industry, however, due to the age of the machines and older control systems becoming obsolescent, we have had to find an upgrade route that does not only keep the machine going, but also provides improvements from the original model and up-to-date technology to future proof the machine.

The upgrade that we have developed for the Flowline is supplied from an automation supplier named Beckhoff. We also use Beckhoff on our new build machines. This gives us better lead times, more understanding of the products and better diagnpostics/ support for our customers. The drive system that we use is called the AX8000 series. These drives are a compact multi axis servo system that use an EtherCAT interface and STO saftey functions. These servo drives, coupled with Beckhoff AM8*** series OCT servo motors provide quicker installations and all round performance increases from any system we have previously used. To drive all of the new system, we are using a Beckhoff IPC controller that runs TwinCAT 3. This links into the system via EtherCAT. All of the machine can now link together via EtherCAT to provide quick and stable communications.

This tutorial will give you step by step guides on the physical upgrade requirements needed when upgrading a Flowline Mk3 to a Flowline Mk3 with Beckhoff AX8000 Control. Each step will provide you with written information and pictures to guide you through the upgrade. Each step will contain necessary information which will also provide you with rationale for the design and an idea of the benefits over using different methods.

- Fichiers

Étape 1 - Familiarisation

The first step does not involve being on site or carrying out any physical tasks. However, trying to gain some familiarisation before carrying out the upgrade can save time and confusion down the line.

Please read through this tutorial before upgrading the machine. The attached files and steps will walk you through the upgrade that somebody else has already experienced. This will give you a free look at any issues or learnings that have already been made.

Étape 2 - Parts Identification and Rectification

This upgrade is covered by BoM R0010201D. This BoM contains all of the parts necessary to complete the upgrade on the machine. This BoM has been created from previous upgrades and from the knowledge of Stuga engineers.

If any extra parts were identified at the time of ordering, they will appear on a seperate BoM for the specific machine build.

Parts will have been picked and checked at Stuga before despatch. However, the first step when arriving on site is to check that all of the parts have arrived and no parts have been damaged or misplaced. The BoM sheets for the parts will be in the boxes with the parts and should be used to cross reference what has been sent.

Attached to this document is a .pdf document of R0010201D that lists all the parts required to complete this upgrade.

If all parts have been cross referenced, move on to step 3. However, if some parts are missing or damaged, please report them to stugaparts@stuga.co.uk and send across the necessary information/ evidence so we can get parts to you. Once this has been sent, move onto step 3.

Étape 3 - Health and Safety

Before any work can be carried out on the machine. You must first ensure that you and the area that you are working in are safe.

Make sure that you ask the customer for their health and safety instructions including first aid and fire safety. Follow all of the health and safety instructions given to you by the customer and Stuga.

Before carrying out any work, ensure the machine is turned off, unplugged and locked off. DO NOT WORK ON LIVE ELECTRICS.

Étape 4 - Removal of Components (MH Cabinet)

List of components to be removed and unwired from the MH cabinet:

- Nextmove E100 - Remove the unit but keep the IO in place as this is where the new IO slices will be wired.

- Nextmove cards (orange IO cards) - Remove the unit but keep the IO in place as this is where the new IO slices will be wired.

- Samsung servo drives - Remove the drives, resistors and wiring.

- Baldor servo drives - Remove the drives, resistors and wiring.

- SA14 unit - Remove the drive and wiring.

- APC - Remove PC, unplug all serial devices, unplug VGA cable and RJ45 cable. The VGA cable will be reused so do not cut this.

- 4 off 10A single pole breakers - There will be 5 breakers in total but we keep 1 breaker in as spare to save time on rewiring the link wires at the top. We will add a 3 pole breaker and another single pole breaker further into the upgrade.

- Timer unit - This can be removed completely.

- Ethernet switch - This will be replaced with a newer model.

- Telephone modem - The can be removed completely.

All of the servo wiring can be removed from the cabinet. The glands that the servo cables enter the cabinet via can also be removed as the new servo cables are bigger.

Étape 5 - Removal of Components (Saw Console)

List of components to be removed and unwired from the Saw console cabinet:

- AcePC - Remove the PC and any wiring that is NOT on a 12 core cable that goes across to the Saw module. The wires that are part of a multicore cable need to be unwired ready for installation into the new IO slices.

- Nextmove ESB - Remove unit and wiring.

- Samsung servo drive - Remove unit and wiring.

- Baldor servo drive - Remove unit and wiring.

- Single pole 10A breaker - Remove wiring and take breaker out.

- Interface relays - All outputs will be +24Vdc switching. If valve bank polarity is incorrect, use an attached TB from Stuga.

- Serial cable for printer - The printer will now run on EtherNET straight from MH cabinet.

The servo drive cables can be removed at this stage. Cut them in half in the Transfer cabinet and pull the remainder through the conduit.

Étape 6 - Removal of Components (Transfer Cabinet)

List of components to remove from the Transfer cabinet:

- BandR PLC - Remove the unit but keep the wiring for the new IO slices.

- Omron PLC - Remove the unit but keep the wiring for the new IO slices.

- Interface Relays - Interface relays no longer needed so relays that interface 'saw and transfer' and 'transfer and multi' can be removed.

Étape 7 - Removal of Components (Cabling)

Étape 8 - Removal of Components (Motors and Gearboxes)

Étape 9 - Removal of Components (General)

List of general components to be removed:

- Monitor on MH side - This will be replaced with a touchscreen.

- Monitor on Saw side - This will be replaced with a screen (not touch).

- Keyboard from Saw side - This will be replaced with a bluetooth keyboard.

- Keyboard from MH side - This will be replaced with a keyboard and mouse combination.

- Mouse from MH side - Remove mouse. Will now be integrated into keyboard.

Étape 10 - Preparation for New Components (MH Side)

Étape 11 - Preperation for New Components (Saw Side)

Étape 12 - Adding New Components (MH Cabinet)

Étape 13 - Adding New Components (Saw Console)

Étape 14 - Adding New Components (Transfer Cabinet)

Étape 15 - Adding New Components (Motors and Gearboxes)

Étape 16 - Adding New Components (General)

Anacondas, Networks, Touchscreens

Étape 17 - Adding Offcut Measuring*

Étape 18 - Adding Zero Speed Detector*

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português