| [version en cours de rédaction] | [version en cours de rédaction] |

(Page créée avec « {{Tuto Details |Main_Picture=TM018B_Microline_and_ZX3_V_Notch_Blade_Setup_ZX3_Ring.jpg |Main_Picture_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.... ») |

|||

| Ligne 37 : | Ligne 37 : | ||

{{EPI}} | {{EPI}} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate> | + | |Step_Title=<translate>Before You Start</translate> |

| − | |Step_Content=<translate></translate> | + | |Step_Content=<translate># Make sure the Datum is correct first. |

| + | # V notch blades are not buckled. | ||

| + | # Check that the profile width is correct for the profile you are testing.</translate> | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Run a VTest</translate> | ||

| + | |Step_Content=<translate>A calibration mnd file has been written to help line up the x offsets called VTEST. This program creates the following pattern on the bottom of the profile using a 10mm spindle and the notching blades themselves: | ||

| + | |||

| + | Run the VTest operation on a length of large outer frame of at least 1m long. Put the operation at a position of 500mm.</translate> | ||

}} | }} | ||

{{Notes}} | {{Notes}} | ||

{{PageLang | {{PageLang | ||

| + | |Language=en | ||

|SourceLanguage=none | |SourceLanguage=none | ||

|IsTranslation=0 | |IsTranslation=0 | ||

| − | |||

}} | }} | ||

{{Tuto Status | {{Tuto Status | ||

|Complete=Draft | |Complete=Draft | ||

}} | }} | ||

Version du 22 octobre 2019 à 10:41

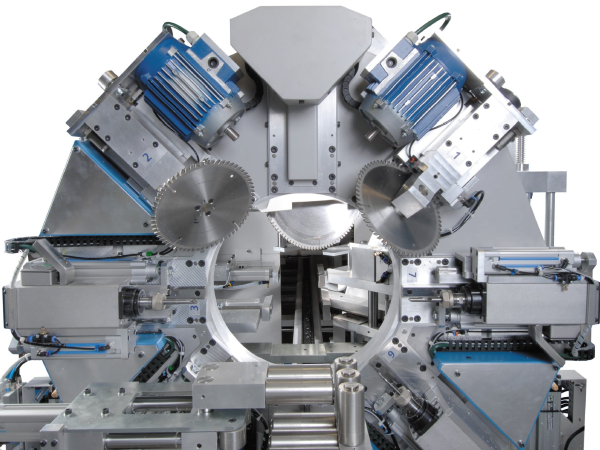

ZX3/Microline/Flowline ZX3 V Notch Blade Setup This module guides the engineer on how to correctly set the V notch blades

Introduction

The engineer will need a reasonable mechanical knowledge, and a working knowledge of the operation of the machine.

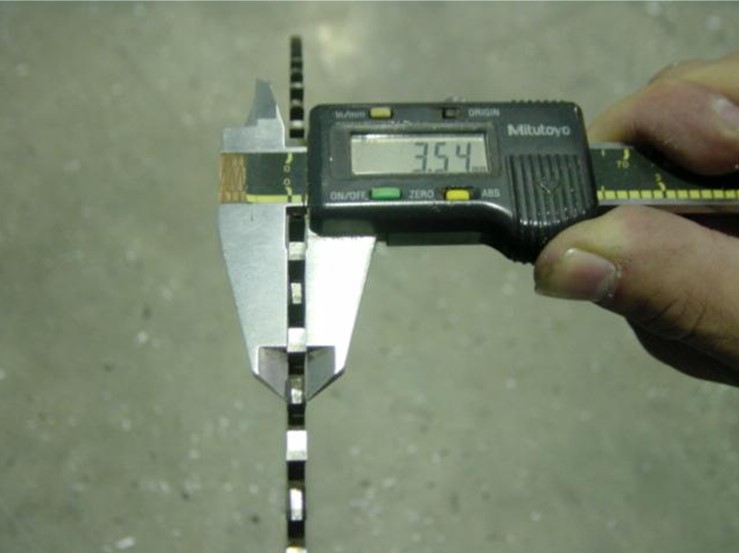

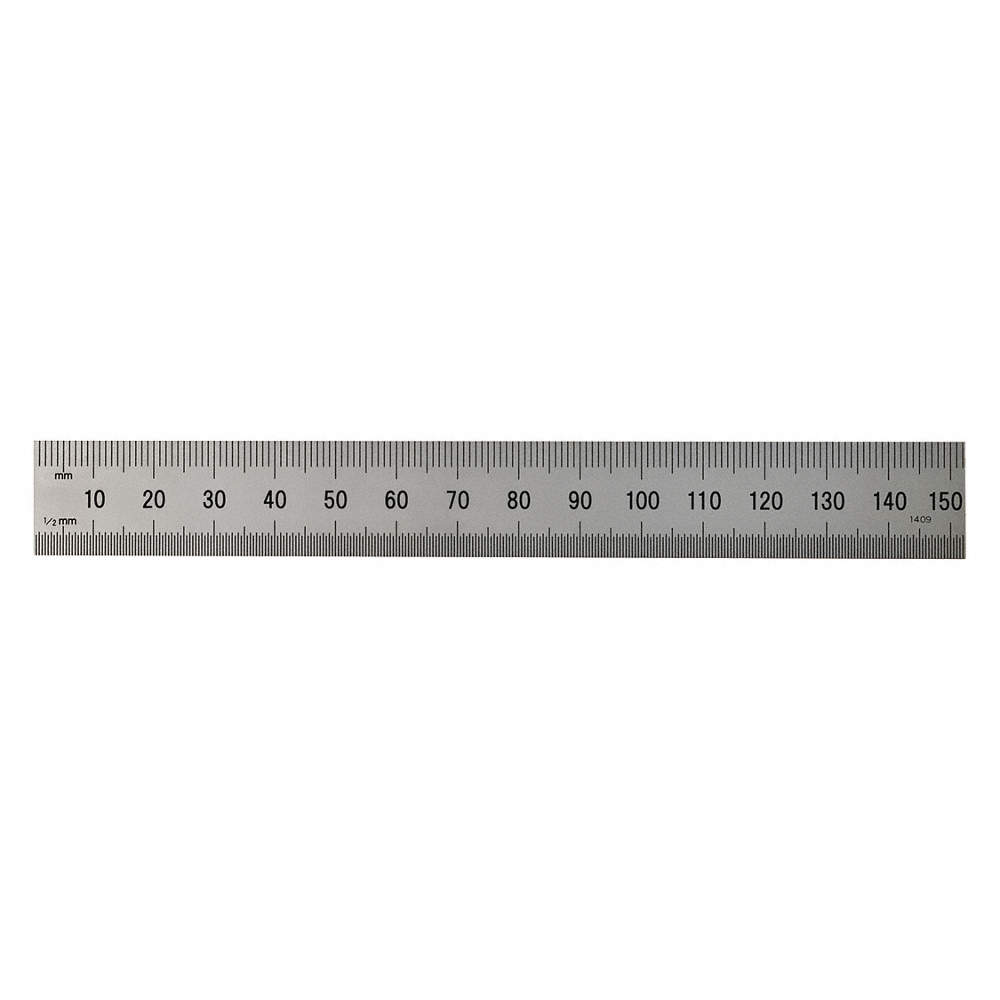

You will need callipers (+/-0.05mm) and an accurate rule

The setting of the V notch blades on a ZX3 revolves around the setting of two groups of parameters:

- V and W axis positions

- Blade offsets for each blade

The rough position of V and W axes is set first, then the individual blade offsets are set, and finally a test is run to tweak the accuracy to gain perfection.

There are two “tweaking” parameters for each blade. The two parameters are:

- Depth offset – how deep into the bar

- X axis offset – position of point of blade relative to the spindle centreline

- Pièces et outils

Pièces et outils

Étape 1 - Before You Start

- Make sure the Datum is correct first.

- V notch blades are not buckled.

- Check that the profile width is correct for the profile you are testing.

Étape 2 - Run a VTest

A calibration mnd file has been written to help line up the x offsets called VTEST. This program creates the following pattern on the bottom of the profile using a 10mm spindle and the notching blades themselves:

Run the VTest operation on a length of large outer frame of at least 1m long. Put the operation at a position of 500mm.

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português