| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 22 : | Ligne 22 : | ||

{{Materials}} | {{Materials}} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate></translate> | + | |Step_Title=<translate>Upgrade Creation and Ordering</translate> |

|Step_Content=<translate></translate> | |Step_Content=<translate></translate> | ||

| + | |Step_Picture_00=Beckhoff_AX8000_Flowline_Upgrade_R0010201D.pdf | ||

}} | }} | ||

{{Notes}} | {{Notes}} | ||

Version du 16 septembre 2019 à 16:37

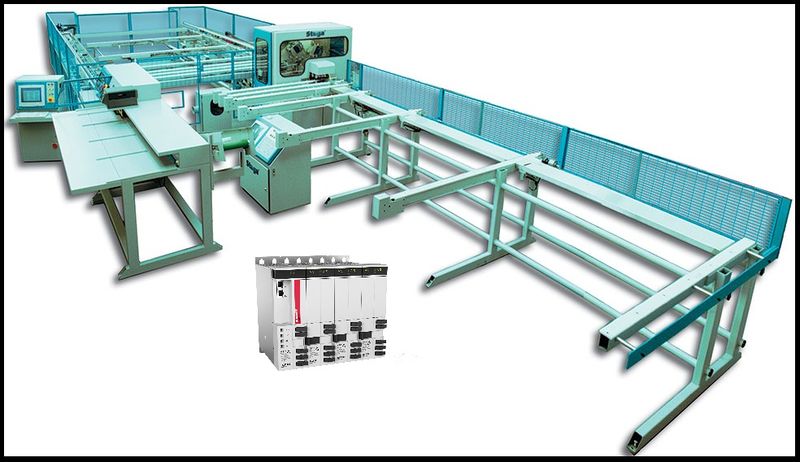

On site upgrade of Flowline Mk3 with Beckhoff AX8000 drives, EtherCAT IO slices and TwinCAT 3 IPC.

Introduction

The Flowline Mk3 is a Stuga built and designed machine for prepping and cutting uPVC windows and doors. The Flowline is the first machine of the Stuga 'U' shaped machines which has prepping and cutting working in the same machine package. The Flowline is still a fantastic machine for the industry, however, due to the age of the machines and older control systems becoming obsolescent, we have had to find an upgrade route that does not only keep the machine going, but also provides improvements from the original model and up-to-date technology to future proof the machine.

The upgrade that we have developed for the Flowline is supplied from an automation supplier named Beckhoff. We also use Beckhoff on our new build machines. This gives us better lead times, more understanding of the products and better diagnpostics/ support for our customers. The drive system that we use is called the AX8000 series. These drives are a compact multi axis servo system that use an EtherCAT interface and STO saftey functions. These servo drives, coupled with Beckhoff AM8*** series OCT servo motors provide quicker installations and all round performance increases from any system we have previously used. To drive all of the new system, we are using a Beckhoff IPC controller that runs TwinCAT 3. This links into the system via EtherCAT. All of the machine can now link together via EtherCAT to provide quick and stable communications.

This tutorial will give you step by step guides on the physical upgrade requirements needed when upgrading a Flowline Mk3 to a Flowline Mk3 with Beckhoff AX8000 Control. Each step will provide you with written information and pictures to guide you through the upgrade. Each step will contain necessary information which will also provide you with rationale for the design and an idea of the benefits over using different methods.

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português