Connection details for interconnecting pneumatic circuits between ZX5 modules

Sommaire

- 1 Introduction

- 2 Étape 1 - Pneumatic pipe identofictions

- 3 Étape 2 - Module A to B

- 4 Étape 3 - Module B Rear pneumatic connections

- 5 Étape 4 - Module D Pneumatic connections

- 6 Étape 5 - Module F connections

- 7 Étape 6 - Module G Saw outfeed connections

- 8 Étape 7 - Waste conveyor blower connection

- 9 Étape 8 - Quality check

- 10 Commentaires

Introduction

Étape 1 - Pneumatic pipe identofictions

All control pneumatic connections will be identified with identification numbers

All permanently fed supply lines will be identified by the use of Red pneumatic pipe

All Emergency stop switched air feeds will be identified by the use of Blue pneumatic pipe

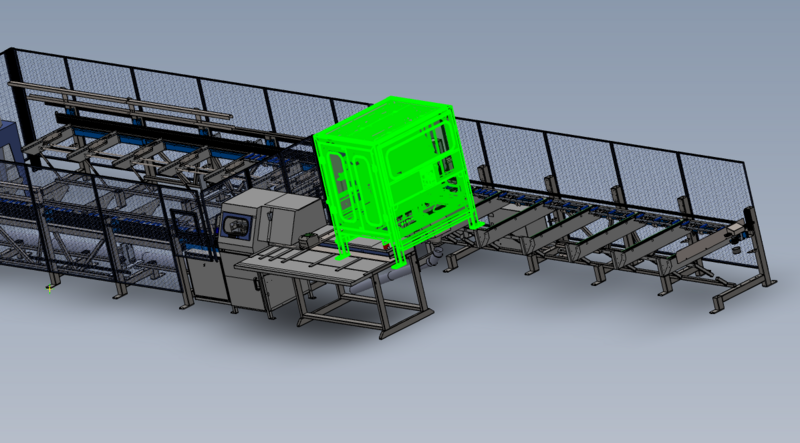

Étape 2 - Module A to B

Machining centre to Machining centre Infeed connections

12mm diameter blue pneumatic pipe from Infeed table to connect to Machining centre main Air service unit . Runs along cable basket on infeed table and drops out of end to connect to air service unit

Mains air connection to machine via PCL connector . Do not connect until all subsequent pneumatic connections are complete

Étape 3 - Module B Rear pneumatic connections

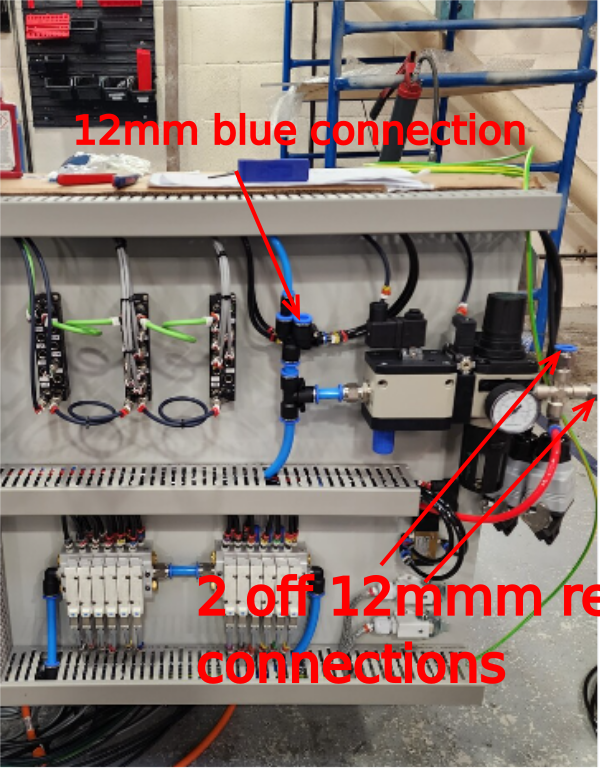

Connections from rear of Module B

- 2 off 12mm diameter Red pneumatic pipes trailing from transfer table wire basket to connect to 12mm bulkhead connections on rear of machining centre. These will be identified as 12mm Red on machining centre

- 1 off 12mm diameter blue pneumatic pipe trailing from module C wire basket to be connected to bulkhead fitting on machining centre. This connection is next to the 2 off red connections and will be identified as 12mm Blue

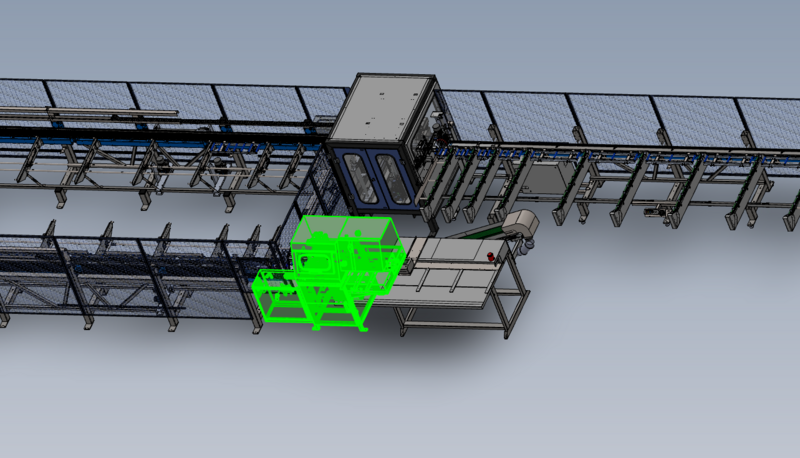

Étape 4 - Module D Pneumatic connections

Transfer cylinder rails will be identified as follows

2299

2309

2319

2329

2339

2349

Connect each loom from cylinder rail to Tee connections directly beneath

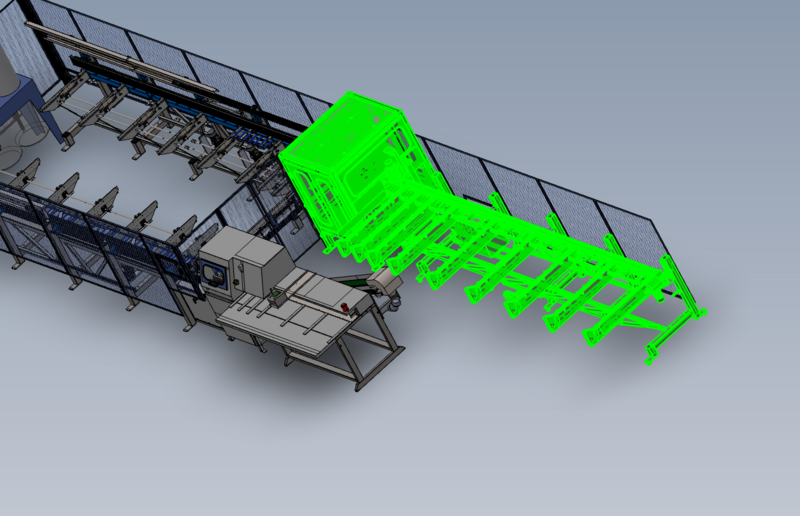

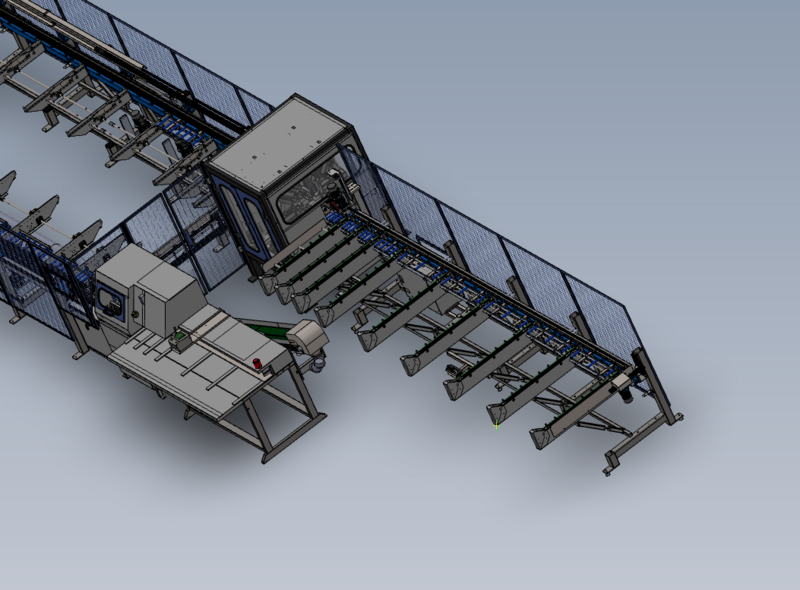

Étape 5 - Module F connections

- 2 off 12mm red pneumatic pipes from transfer table to connect to saw service unit

- 1 off 12mm diameter blue trailing from saw infeed module E to connect to saw service unit

Étape 6 - Module G Saw outfeed connections

8mm Blue diameter trailing from Saw module requires connecting to valve bank attached to outfeed frame

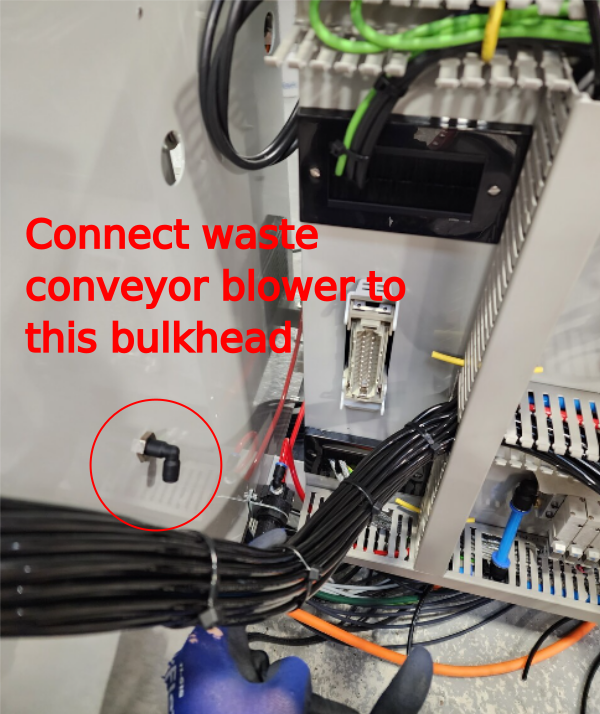

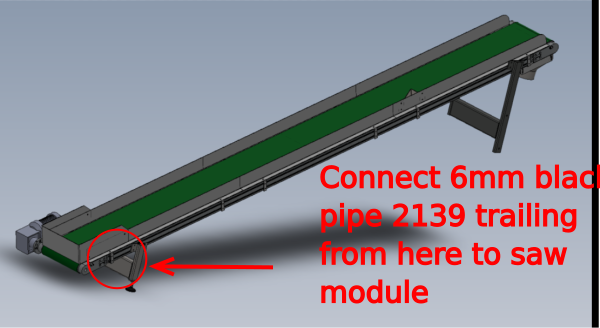

Étape 7 - Waste conveyor blower connection

Connect waste conveyor 6mm black pipe identified as 2139 to be connected to saw module bulkhead connection

Étape 8 - Quality check

Once all pneumatic circuits are connected, all areas should be inspected for audible air leaks, and rectified as discovered

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português