How to utilise the additional controls in the winMulti software v6 to improve optimising on Doors and Door frames

Sommaire

Problem

The on-board optimiser uses a method to try to get the best use out of a bar. This is controlled by a parameter called the “Optimiser Tolerance”. Normally it is set to 50mm, which means that a combination of pieces leading to less than 50mm waste is classed as “Passed”. This works well when there is a good selection of piece sizes to try from, but can lead to problems when there are long pieces of the same length. This happens particularly on doors and composite door outer frames.

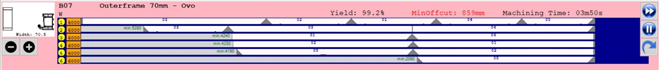

The picture shows the bar queue after standard optimising of 5 composite door frames. The optimiser has done a great job of the first bar, but then there are no options left for the following bars, and it uses 6 full lengths instead of 5.

Solution

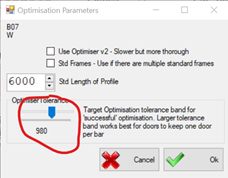

Clicking on the reoptimize button brings up a window to allow the operator to remedy the situation

This screen allows the optimiser tolerance to be changed “on the fly”. The default is 50, but in this case it can be increased to around 1000.

Click on OK and this profile will be reoptimized with the new parameter

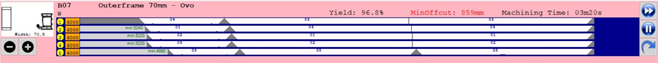

The same pieces are now optimised into 5 lengths instead of 6.

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português