How to solve a Timeout on V Blade Out or Home Error

Problem

Fault codes

001 Timeout on VI Blade Home

002 Timeout on VI Blade Out

003 Timeout on VO Blade Home

004 Timeout on VO Blade Out

005 Timeout on WI Blade Home

006 Timeout on WI Blade Out

007 Timeout on WO Blade Home

008 Timeout on WO Blade Out

This means that the Inputs at the top or bottom stroke of the V notching cylinders are not being made within a set number of seconds of the Output Valve and being operated (timeout).

| Message | V Notch Station | Input Reference | Valve Reference |

|---|---|---|---|

| Timeout on VI Blade Home | Front Infeed Side | VICTH | Y32 VICUT |

| Timeout on VI Blade Out | Front Infeed Side | VICTO | Y32 VICUT |

| Timeout on VO Blade Home | Front Outfeed Side | VOCTH | Y33 VOCUT |

| Timeout on VO Blade Out | Front Outfeed Side | VOCTO | Y33 VOCUT |

| Timeout on WI Blade Home | Rear Infeed Side | WICTH | Y36 WICUT |

| Timeout on WI Blade Out | Rear Infeed Side | WICTO | Y36 WICUT |

| Timeout on WO Blade Home | Rear Outfeed Side | WOCTH | Y37 WOCUT |

| Timeout on WO Blade Out | Rear Outfeed Side | WOCTO | Y37 WOCUT |

Solution

Potential Root Causes

Movement is too slow because:

- Blades are really blunt

- Hydrocheck speed damper is not adjusted correctly or faulty.

- Faulty or sticky air valves (water damage) that are not switching on and have a delay

Movement is correct speed but input is not feeding back

- Faulty reed switch

- Faulty connection to reed switch

- Position of reed switch not correct on cylinder

1 Increase the timeout

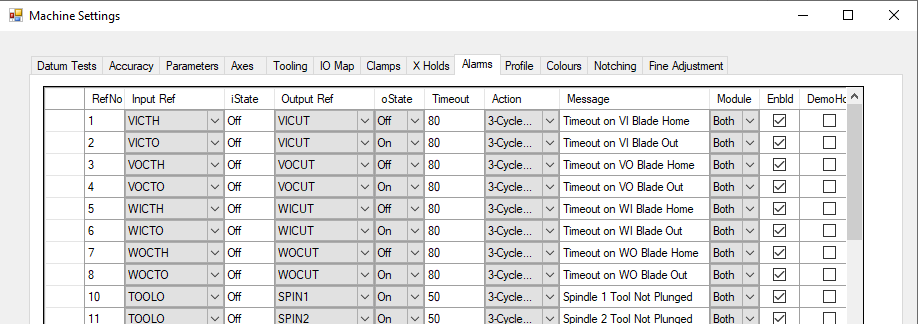

In Settings ->Alarms tab

The diagram shows a timeout of 8 seconds (80). To increase by 2 seconds, make 80 into 100 on the Timeout column.

It is expected that 8 seconds should be ample for the v notch stroke to happen, so this will only mask the real root cause, possibly

2 Disable the alarm

If you are certain that the blade is operating correctly, you can disable the alarm by unticking the "Enbld" tick box for the alarm that keeps triggering.

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português