Technical Bulletin for Nextmove Card Obsolescence Originally published 17/07/09

Technical Bulletin

| TB Number: | 0141-3 |

| Originator: | Gareth Green |

| Machine: | Flowlines; ZX; Microlines pre 2008 |

| Date: | 17/07/09 |

| Circulate to: | Stuga Customers F001-F085, M001–M009, Z001-Z026 |

| Title: | Part Obsolescence Notice: Nextmove PC Controller

Revision 1 – Software front end revision Revision 2 – USB Cable, installation timescale Revision 3 – Include Saw PC and motion controller Revision 4 – Microline Machine additions |

NOTE: This Technical Bulletin has been superseded by https://stuga.dokit.app/wiki/TB0438_Part_Obsolescence_Notice_Nextmove_E100_and_ESB

Details

Your Stuga machine has a control system in it based around the Baldor “Nextmove” motion control card. This system consists of a card located in the main PC, plus 3 off “CAN node” expansion cards. It is responsible for the entire interface to the movement of the machine, controlling all the motion axes, reading the sensors, and activating the pneumatics. As is always the way with new technology, the system became obsolete with our suppliers some time ago, due to the obsolescence of many of the components in the card by IC manufacturers further up the supply chain. Stuga reacted by purchasing all the available stock at that time in order to continue the support of our product. Along with this, we developed a new software system which works with the next generation of Nextmove cards and works on a Standard Windows interface with a touchscreen. This system has been installed on all new machines and refurbishments since August 2010.

Upgrade

The stocks of replacement Nextmove cards and of the CAN I/O Nodes have now been exhausted, and therefore if any of these parts has a critical failure, we are unable to replace it. In the unlikely event that the card is repairable, it can take up to four weeks to turn around. We have been aware of this situation and have been developing the new software system to run on older machines. We are now able to offer an alternative to the old Nextmove card, but due to the limitations of the old PC hardware, many other control system components need to be replaced. We have perfected this upgrade into a kit that can be fitted on site quickly and efficiently by our engineering team. The kit comprises these brand new components:

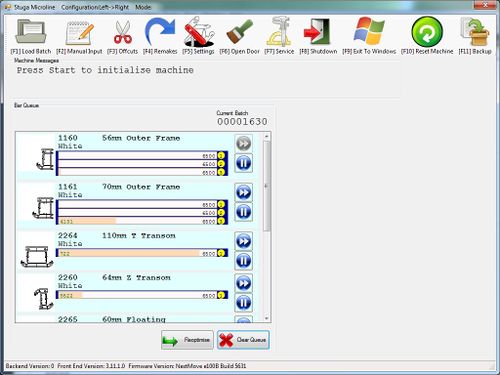

- winMulti Control Software. The system has been proven and new customers love the graphical display of the batch data.

- Windows PCs. These come with a Windows 10 operating system. The software is written using Microsoft .NET techniques, so is future-proofed for new versions of windows. The PC in both the sawing cabinet and Machining module is replaced. **

- Flat Panel Display with Touchscreen. The touchscreen is far superior to the mouse control for machine batch loading, and for standard windows functions

- Nextmove E100 Card. This replaces the old Nextmove card, however the interface now used with the new software (USB cable) means that the big disadvantage of the old system where the software was tied to the old hardware has been completely removed. The system is future-proofed.

- Nextmove ESB Card. Replaces the obsolete component in the sawing cabinet **

- Beckhoff I/O Expansion units – these replaces the orange coloured CAN Input / Output nodes. This allows us to easily expand the I/O for future upgrades. The “nodes” work on an industry-standard “CANOpen” protocol, so again, these components are future proofed.

- Connection Cables

- Fitting, Testing. Fitting, testing and training takes 4-5 days

- Operator training on winMulti system. Our engineer will remain on site for 2 full days to ensure the operator is completely familiar with the new system, and everything is working correctly.

The upgrade kit has been fully fitted and tested on many older style machines.

Other Benefits

The latest software is being continually developed to add more features and benefits to the flowline control system

· Teamviewer remote diagnostics. Support from Stuga HQ can be given immediately over the internet from any of the Stuga Staff. They can take over control of the operator screens to instantly fix IT problems and operator issues.

· Visual bar queue identification. The screen displays a scale drawing of the profile making identification for inexperienced operators much easier

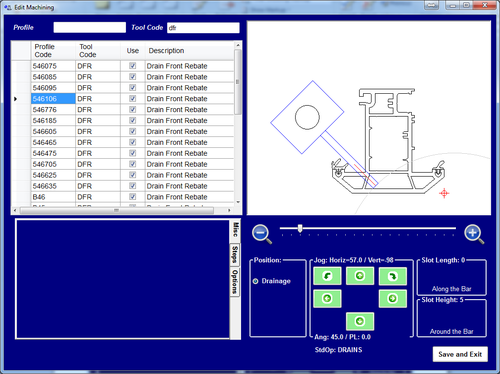

· Visual tool code editing. Cutter positions are displayed graphically to the profile, allowing small adjustments to cutter positions to be made easily

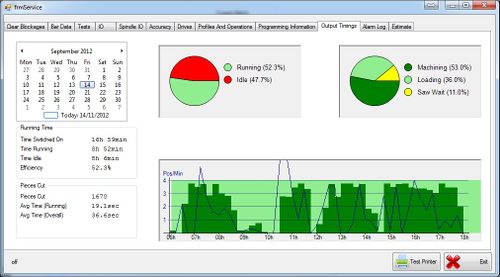

· Production reports. A graphical display of machine output is displayed for machine / operator performance analysis.

· Optional mechanical upgrades are available that are only compatible with the latest software (details on request)

o Auto bar length measuring and optimizing**

o High speed spindle and double plunge upgrade, increases machine output by up to 50%**

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português