Instructions on how to use the RAG Report Mk2 Monday board

Introduction

This dokit describes the Mk2 format RAG report as used on a Monday board. The Mk2 board takes the feedback received from engineers and the team from the Mk1 board

The RAG process can be seen here

Why a Monday RAG Report?

The RAG reports are becoming very common and a much-requested service from our customers. This has placed a higher workload on all aspects of the service department. It is important to standardise and streamline this process

- The RAG reports need to be consistent, across all staff

- The customer interaction with the process. The Monday board allows the data to be shared across teams, sites, departments and customers, real-time

- Real time feedback. The Monday board allows comments, photos, videos, expertise and opinion to be shared across the entire service department instantly

- Parts identification is a bottle-neck that requires specialist memory and knowledge. This knowledge needs to be shared and documented and a RAG process is a way to do this

- Clarity to the engineers on which upgrades are available

- Efficiency. The goal of this process is to make the RAG inspection quicker and reduce the after-visit processing for the engineer and the parts identification team

- Accuracy. Remove the human errors in the system

Instructions / Key Points

Use a large screen device

Although the Monday board works on a phone size screen, this will be frustrating if this is the only device used. You will not get the benefits of the additional features now added. The beauty of the Monday system is that you can have the board open on multiple devices, eg a phone and the machine's touchscreen - whatever works best

Internet connection is important

The device selection will depend on which device has the best internet - there is a lot of data in this Monday board and it will be frustrating if the connection speed slows it down. All engineers have been issued with a tablet and a WiFi extender. It will make a massive difference if you use these items.

This is a checklist - so fill it in as you go

The size of the list may look daunting at first, but these are all points that a thorough engineer is expected to check on a RAG anyway. The checklist wont work if you fill it all in afterwards, and will no doubt seem like a massive chore if you do. Changes have been made so that each item on the checklist needs a simple click / tick to say it is done. More detail is then added in the parts identification subitems

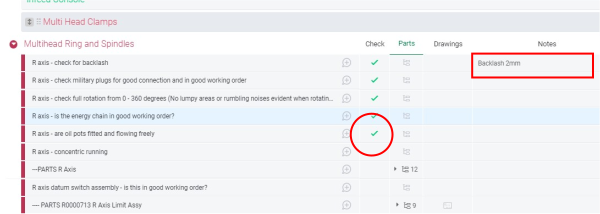

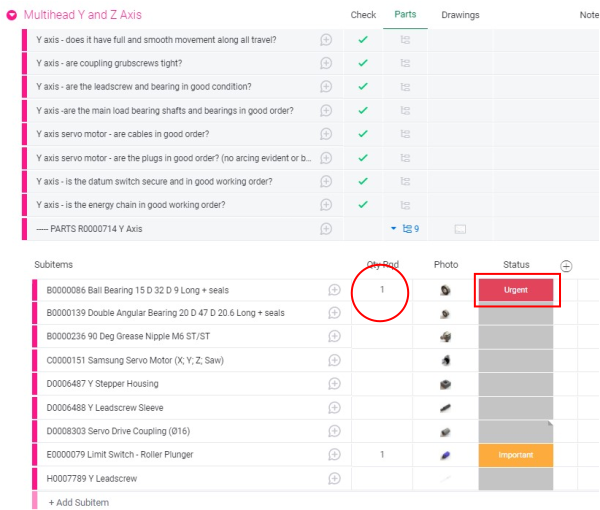

| Use the Check column to keep track of where you are

Add any notes in the notes column, in particular, use this column to state what needs remedial action to put the issue right. | |

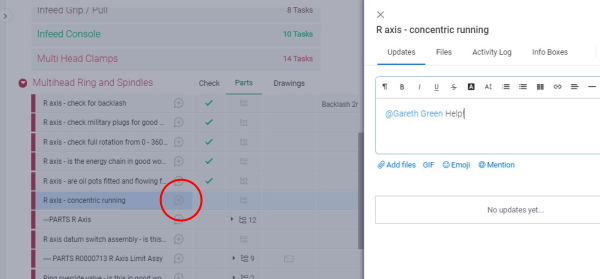

Use the updates to

|

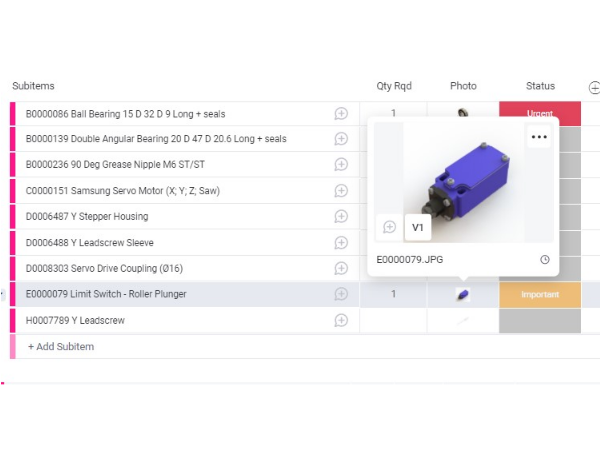

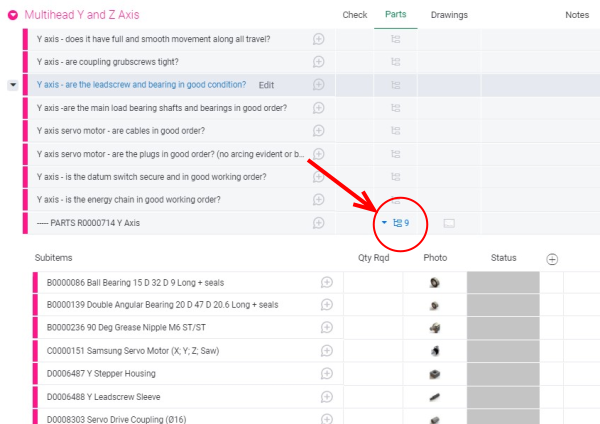

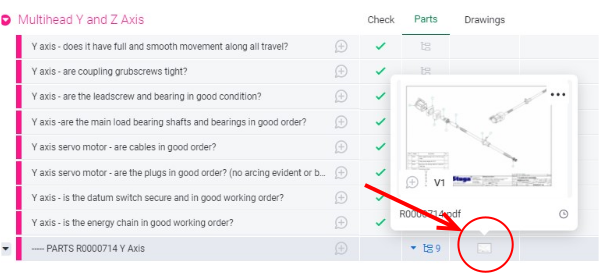

| Parts Identification areas are identified with

----PARTS xxxxxx

Clicking on this toggles the parts identification list

| |

| In most cases of a ----PARTS item, there will be links to one or more relevant exploded views. This will further help parts identification

Clicking will open the full screen version | |

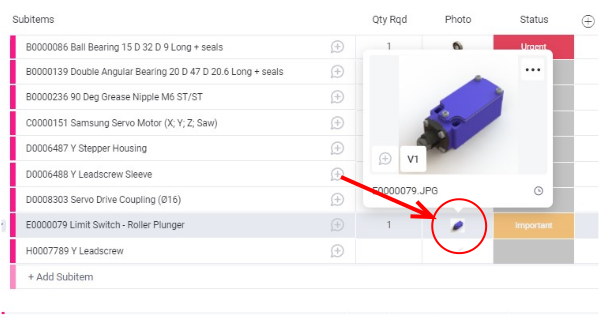

| Each Part Item will have a thumbnail picture of the part to help identification even more | |

| Fill in the Qty of any parts needed and set the RAG status on a part level basis |

Part Not in the List?

If a part is not on the list, add the description in the + Add Subitem

Add any detail and identification photos in the update bubble for the subitem - @service while you are doing it in case the service team need more information and can strike up a conversation.

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português