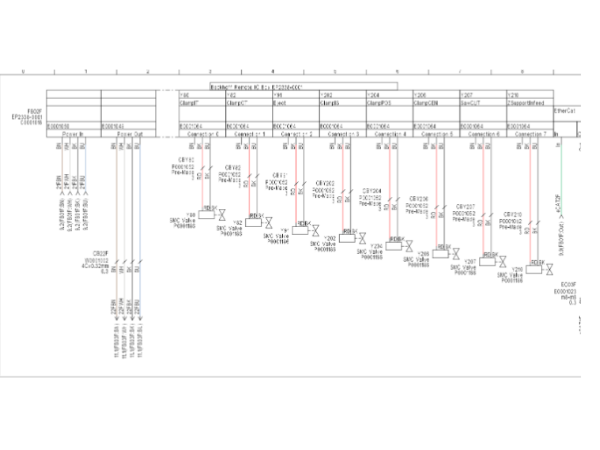

Details for manual pneumatic output testing on module

Sommaire

- 1 Introduction

- 2 Étape 1 - Safety

- 3 Étape 2 - Y206 Centralise

- 4 Étape 3 - Y207 saw cut

- 5 Étape 4 - Y210 Z support infeed

- 6 Étape 5 - Y212 Hi low pressure

- 7 Étape 6 - Y213 Saw blowers

- 8 Étape 7 - Y214 Z turret infeed

- 9 Étape 8 - Y215 Z turret outfeed

- 10 Étape 9 - Y224 Z support outfeed

- 11 Étape 10 - output testing complete

- 12 Commentaires

Introduction

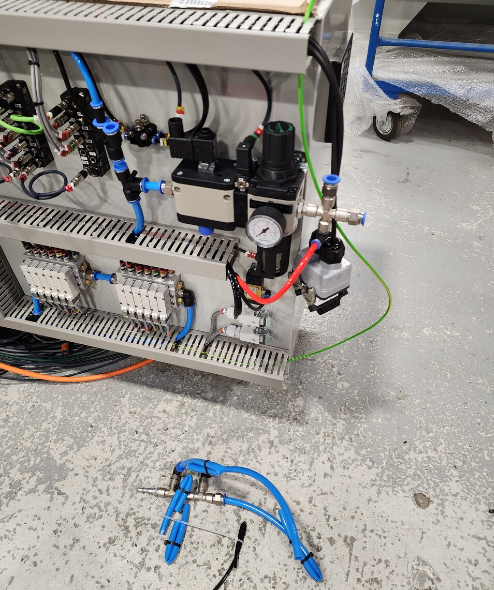

Tools Required

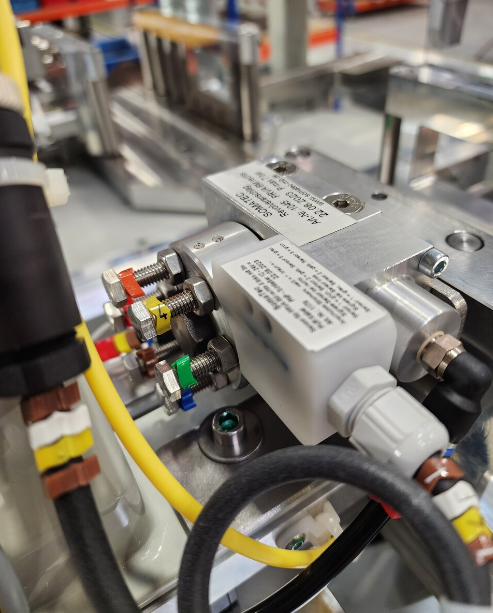

PCL airline connection

12mm blanking ports

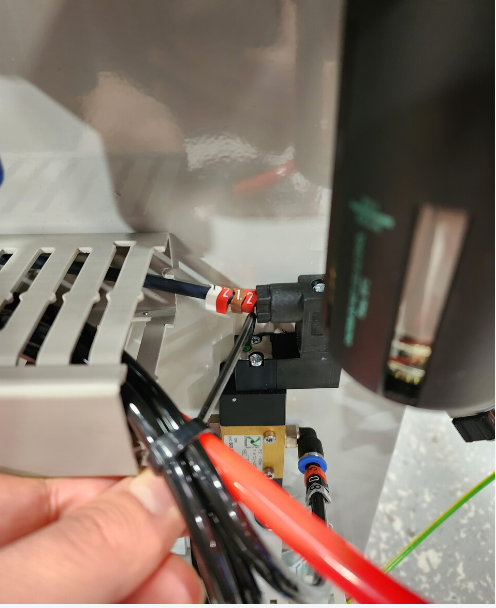

Valve Manual over ride tool

Standard screwdriver set

Additional colleague when setting regulator pressures for outputs

Parts required

Étape 1 - Safety

Output testing will require valve operation with no e/s circuit

Ensure the following

Work area is clear from all components not required for testing

All colleagues are aware of the procedure being undertaken

No additional colleagues are working on the module

PCL coupling is accessible to release pressure in case of emergency

Testing procedure is fully adhered to

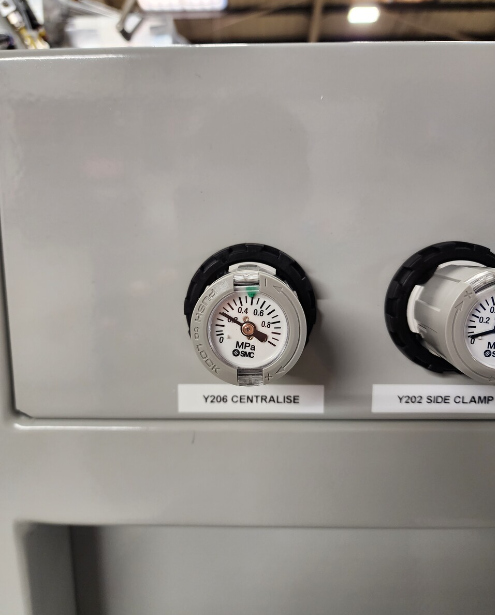

Étape 2 - Y206 Centralise

Fire and hold valve

Set regulator to 0.2 M.P.A

Saw head should move towards rear of machine

Should retract when valve released

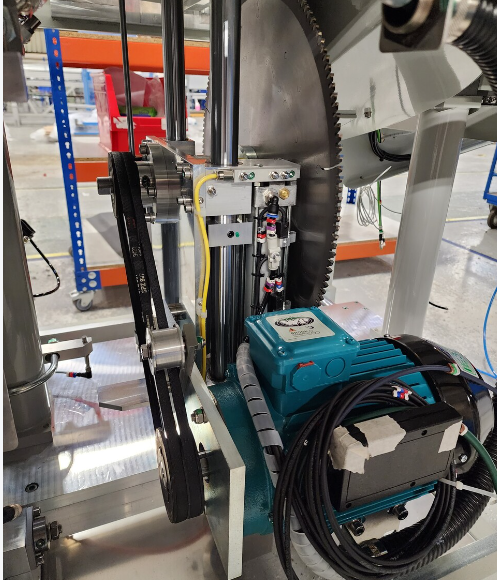

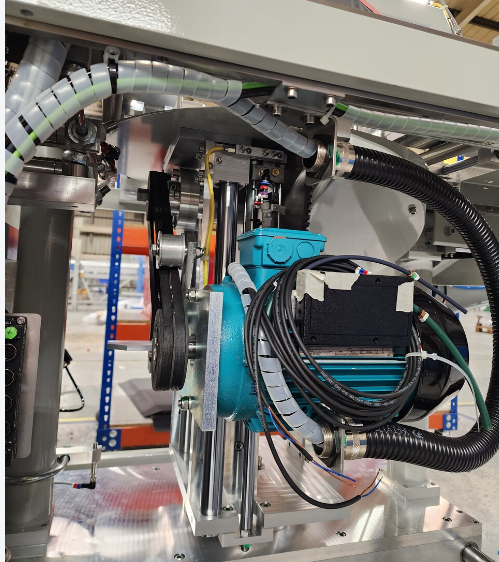

Étape 3 - Y207 saw cut

Fire and hold valve

Saw head should raise up

Should retract when valve released

Adjust damper thumb wheel to allow good speed when saw cut stroke upwards

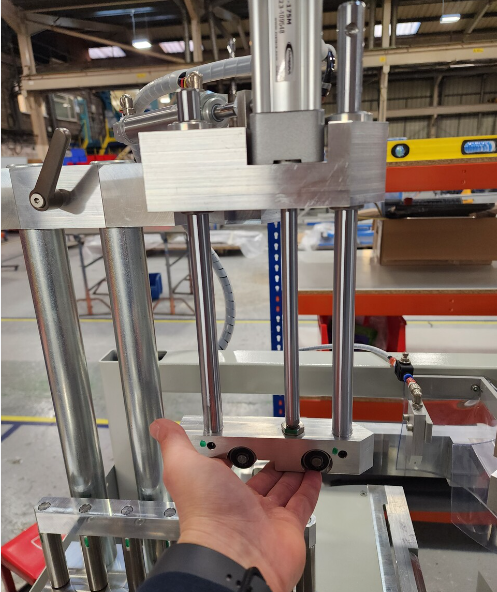

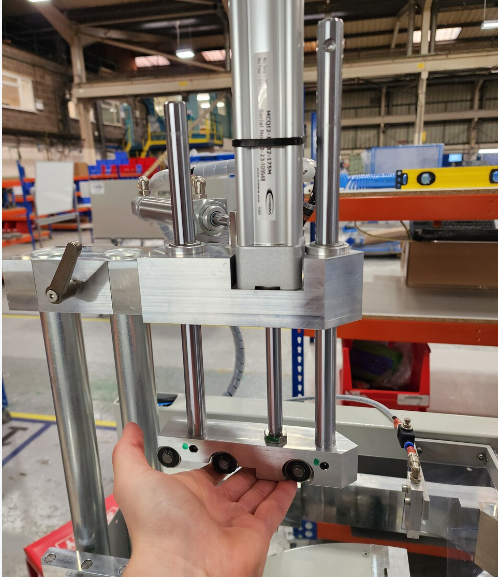

Étape 4 - Y210 Z support infeed

Fire and hold valve

Infeed side z block should fire towards back fence

Should retract when valve released

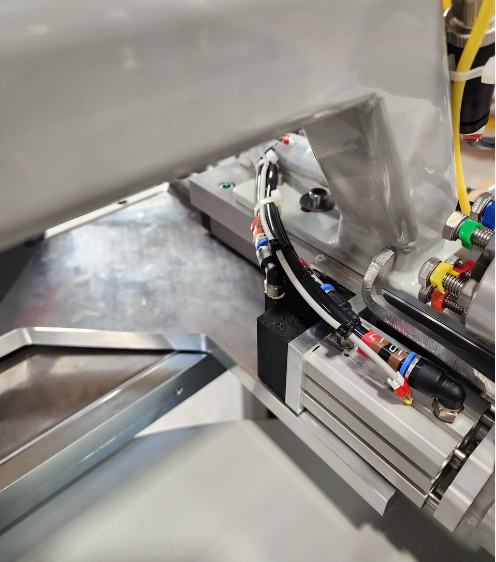

Étape 5 - Y212 Hi low pressure

assistance required from colleague

Fire and hold Y80 output , infeed top clamp should move down. Keep Y80 held down

Top clamp block pressure should be weak enough to override by hand and move clamp back towards cylinder

Additionally fire Y212, this should switch clamp to high pressure and stop clamp being able to be over ridden by hand

Étape 6 - Y213 Saw blowers

Fire and hold valve

Blowers should switch on

Check operation of inline flow controllers .

When fully closed air flow should stop completely. If air flow can not be completely stopped by flow controller, it is fitted the wrong way around. Change and recheck if this occurs

Étape 7 - Y214 Z turret infeed

Fire and hold valve

Infeed turret should rotate once

Release and fire valve again and turret should again rotate one position

Étape 8 - Y215 Z turret outfeed

Fire and hold valve

Outfeed turret should rotate once

Release and fire valve again and turret should again rotate one position

Étape 9 - Y224 Z support outfeed

Fire and hold valve

Outfeed side z block should fire towards back fence

Should retract when valve released

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português