Centralise mounting details

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Attach centralise cylinder bracket

- 4 Étape 3 - Attach centralise lever

- 5 Étape 4 - Position centralise bar

- 6 Étape 5 - Attach Tie Rod

- 7 Étape 6 - Fit centralise switch bracket

- 8 Étape 7 - Attach damper and None Centralise Bracket

- 9 Commentaires

Introduction

Tools Required

Standard hex key set

Standard spanner set

Steel rule 600mm

Soft hammer

Parts Required

D0004672 Centralise Sensor Bracket x 1

D0004972 None Centralise Bracket x 1

D0004622 centralise cylinder spacer x 1

R0000572 Bench Assemble Centralise Assembly

Étape 1 - Unless otherwise stated

Use locktite 243 on all fasteners

Use loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

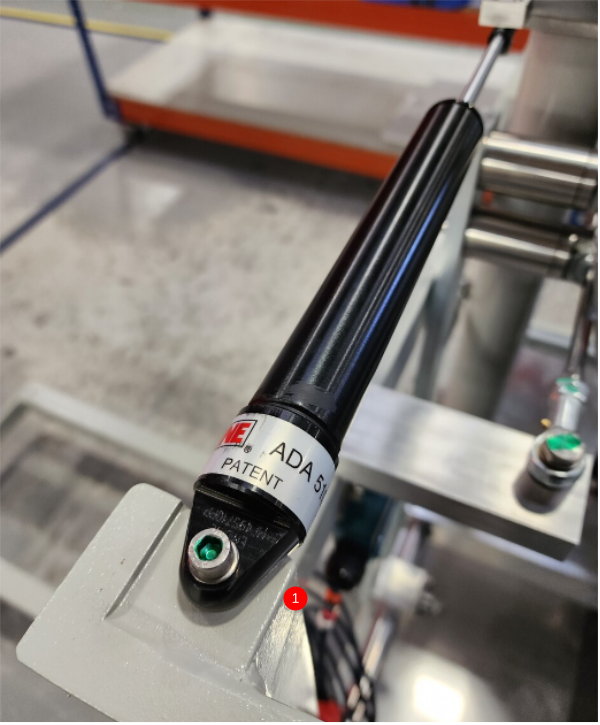

Étape 2 - Attach centralise cylinder bracket

Attach d0004542 bracket to frame as shown . Use 2 off M8 x 40 socket caps with A form washers

Étape 3 - Attach centralise lever

1 Attach prebuilt centralise lever to bottom turntable shaft, use 2 off M8 x35 socket caps to mount clamp , but do no add tension to fasteners

2 Attach cylinder rod end to centralise bracket as shown using 1 off M10 x 50 set bolt and A form washer . Fit spacer D0004622 between block and spherical bearing . Do not add adhesive to this fastener yet

Étape 4 - Position centralise bar

1 Set position of centralise bar to 145mm on bottom shaft

2 Finalise tension on clamp bracket . ENSURE fasteners are tightened equally as this clamp can effect position of top cylinder when tensioned

3 Check cylinder position by removing indicated ?M10 set bolt and spacer and checking that spherical bearing is still aligned to M10 tapped hole when cylinder is in a fully closed position

4 Add adhesive to M10 set bolt and finalise bolt

5 Check movement is free and consistent with cylinder attached

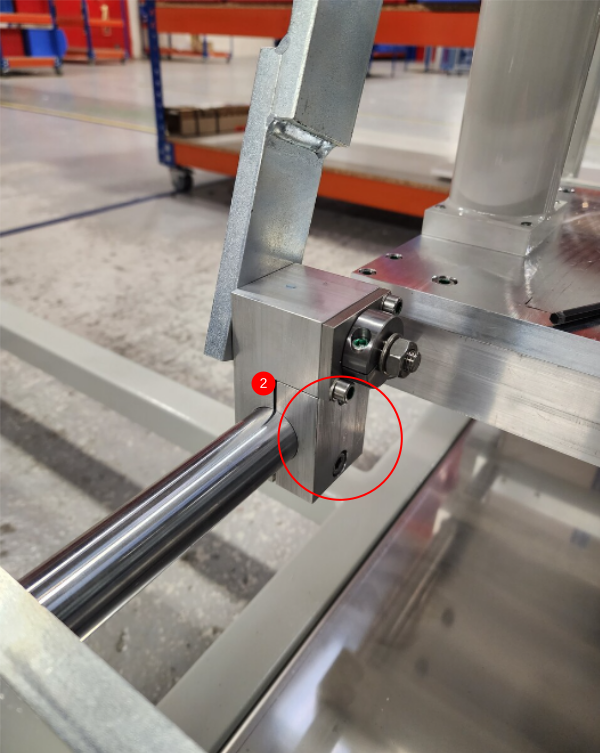

Étape 5 - Attach Tie Rod

Attach tie rod to spindle post and centralise bar as shown

Use fixings as follows

1 M10 x 30 set bolt, A Form washer, Spherical bearing 2 x M10 A form washer

2 Attach end shown (Non adjustable end ) to saw post

3 Attach end shown (adjustable end ) to centralise bar

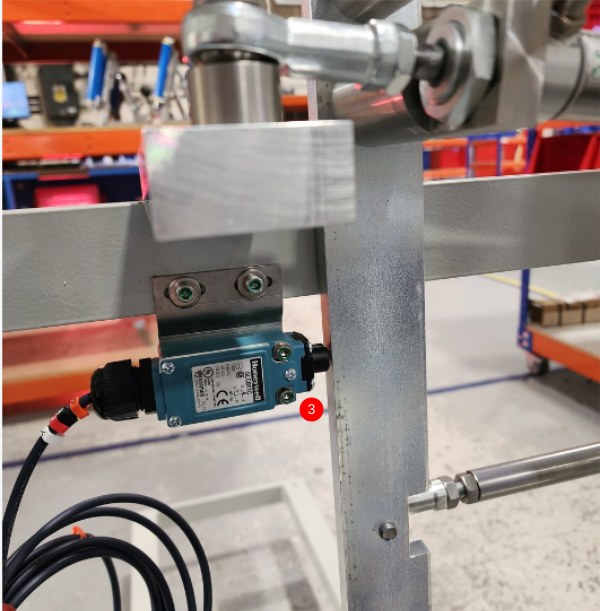

Étape 6 - Fit centralise switch bracket

1 Fit centralise switch bracket to frame using 2 off M5 x 16 socket caps and heavy M5 washers.

2 Fit pre wired X203 switch assembly (from electrical department ) To bracket using 2 off M4 x 40 socket caps, 4 A form washers and 2 off M4 nyloc nuts

3 Set switch position so roller plunge is just made when centralise lever is in its most forward position

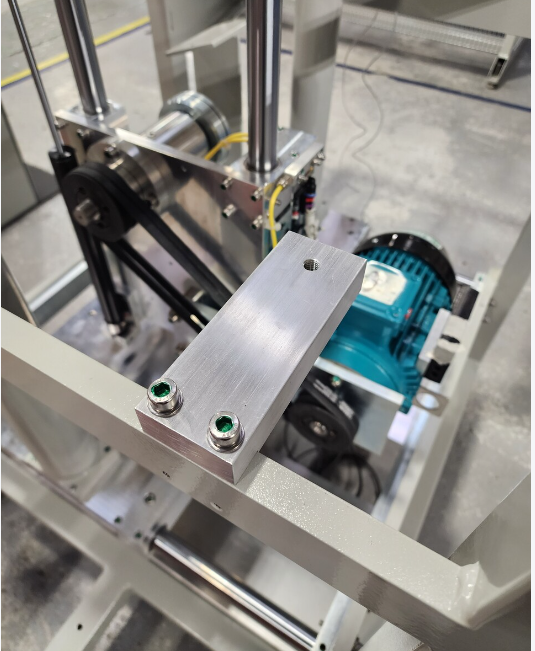

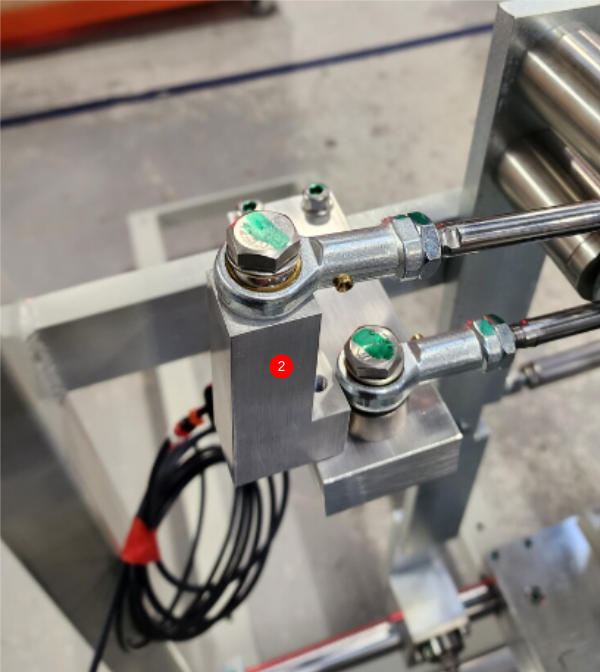

Étape 7 - Attach damper and None Centralise Bracket

1 Attach pre built damper to frame using M6 x 35 socket cap reduced in length by 10mm, M6 A form washer and Securing M5 x 12 flat grubscrew.

Do not fully tension M6 , as movement is required by damper. Hold position of M6 with M5 grubscrew

2 Fix None Centralise Bracket to top cylinder as shown using M10 x 30 set bolt and A form washer

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português