Bench assembly details for roller fences

Introduction

Tools Required

Standard hex key set

1 meter straight edge

Feeler gauges

Bearing dolly for B0000245 Needle Bearing

Parts Required

B0000245 Needle Bearing 12 D 16 D 10 Long (ENA) x 20

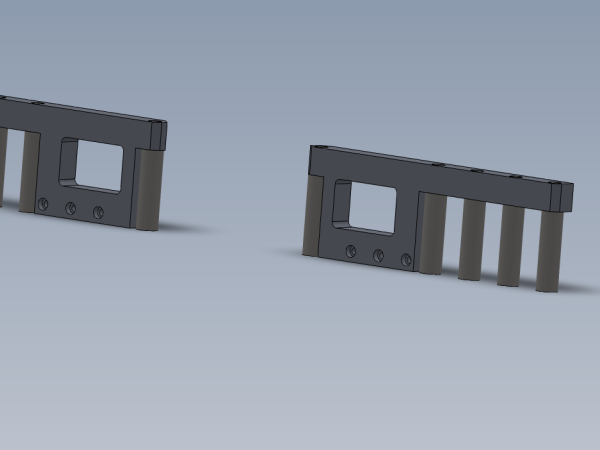

D0005183 Roller Backfence (D7443) x 1

D0005184 Guide Roller x 10

D0005186 Guide Pin Washer x 10

D0007443 Roller Backfence OH (D5183) x 1

H0005185 Shaft 12mm: 90.5 Saw Fence Roller Pin x 10

Étape 1 - Unless otherwise stated

All bolts to have Loctite 243 adhesive applied unless otherwise stated

All Threaded Pneumatic connections to have Loctite 570 applied

All bolts to be pen marked once adhesive applied and correct tension added

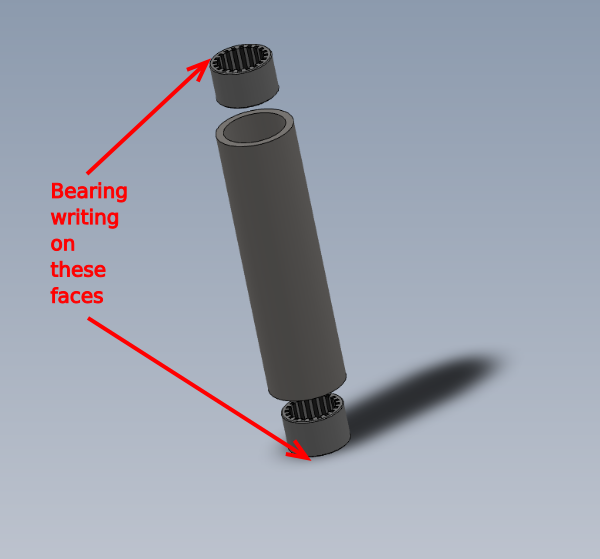

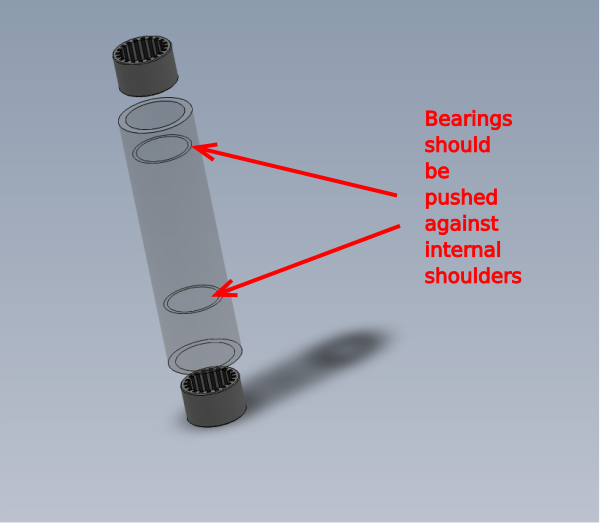

Étape 2 - Fit bearings to rollers

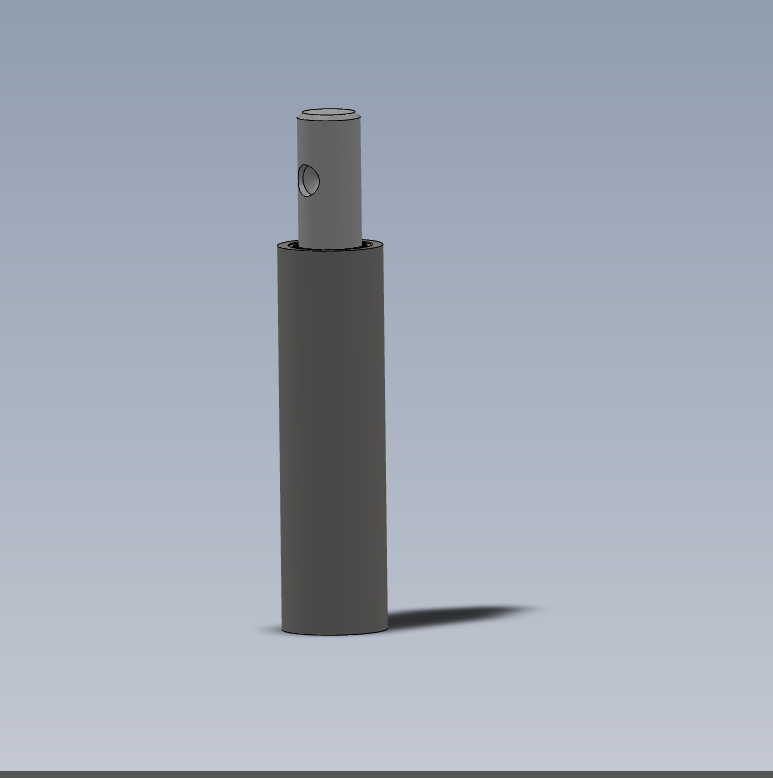

Assemble 10 off D0005184 Guide Roller

Each roller has 2 off B0000245 Needle Bearing fitted

Ensure bearings and rollers are thoroughly degreased before fitting

Ensure bearings are fitted correct orientation . Writing on edge of bearing should be face outwards

Use bearing dolly and push bearing down to should within roller body

Étape 4 - Fit guide pin washers

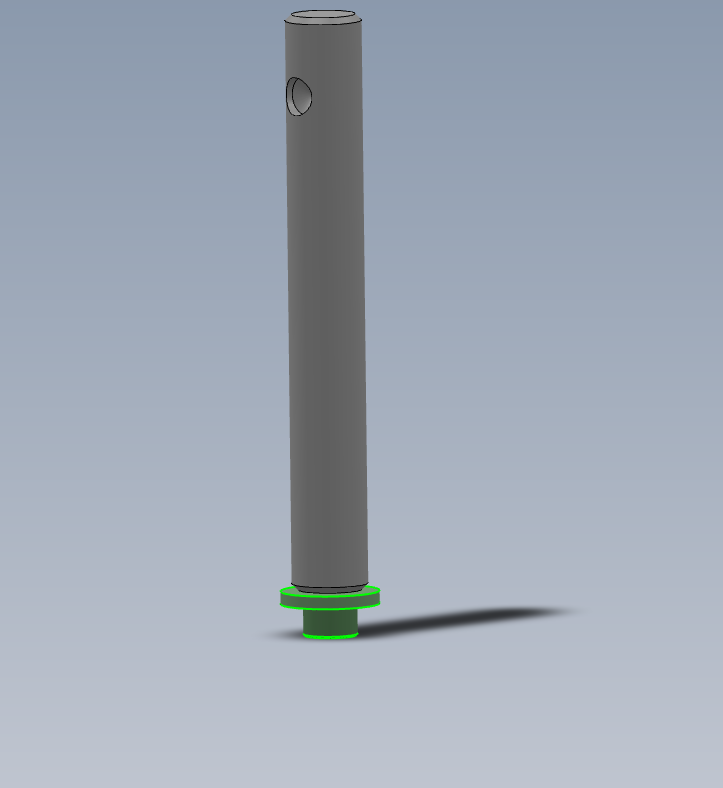

Fit 10 off D0005186 Guide Pin Washer to H0005185 Shaft 12mm: 90.5 Saw Fence Roller Pin

Hold shaft in vice and use M5 x 12 socket cap to secure washer to end of shaft . Finalise bolt with loctite 243

Repeat for all ten shafts/washers

Étape 5 - Fit Rollers

10 off

Fit pre assembled rollers to assembled shafts

clean excess grease from shafts once fitted

Étape 6 - Shaft orientation

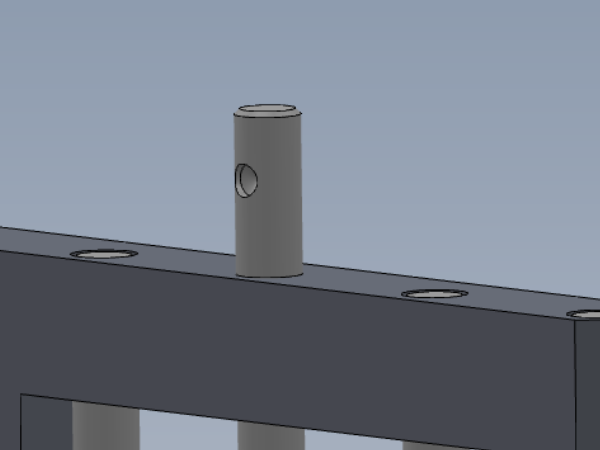

Dimples in H0005185 Shaft are not used in this application.

When fitting shaft , position dimple 180 degrees opposing M6 fixing point in backfence

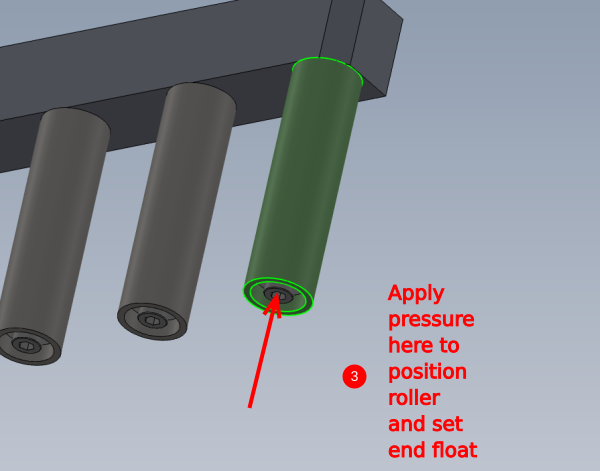

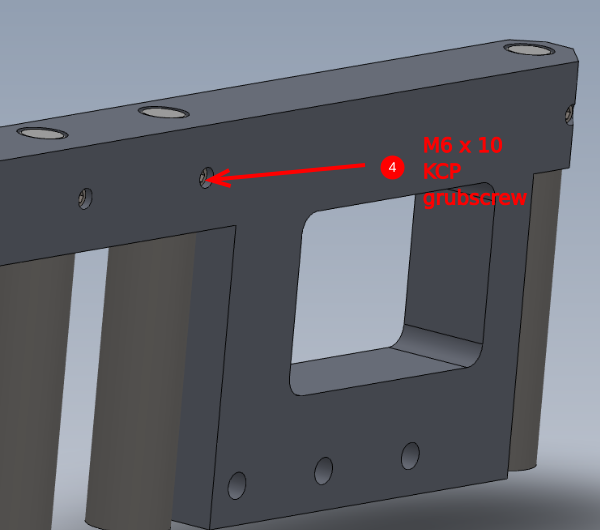

Étape 7 - Position rollers

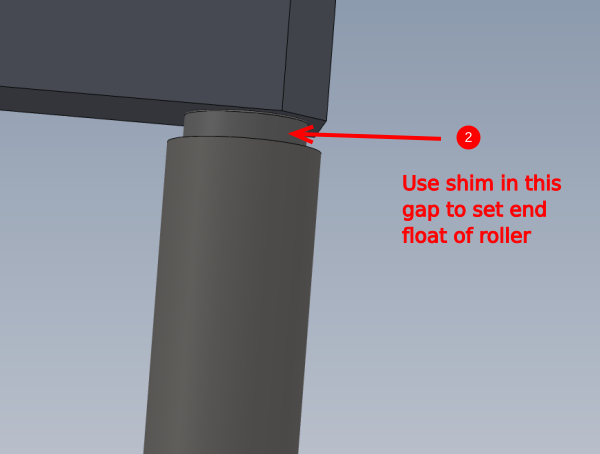

1 insert shaft into bore following previous step information

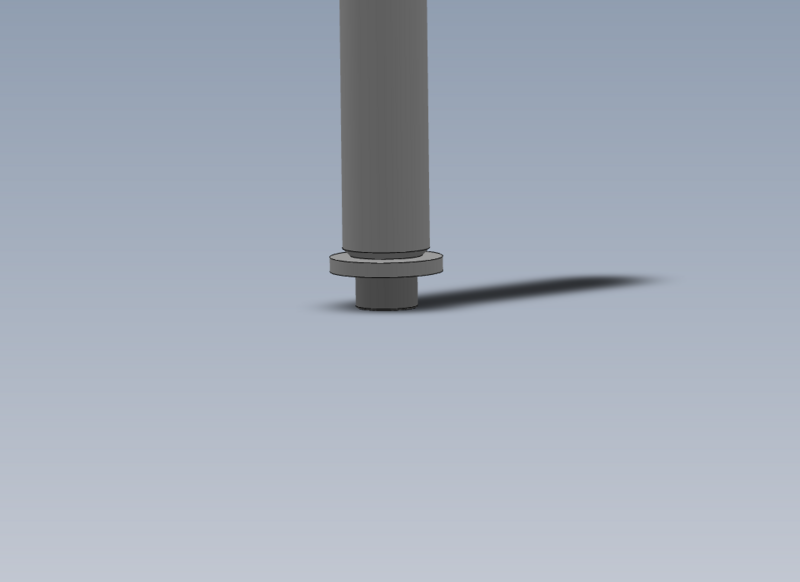

2 Insert 0.125mm/0.005" shim between roller and backfence at indicated point

3 Apply very light hand pressure to area shown to position shaft correctly

4 fit and finalise M6 x 10 kcp grubscrew to secure shaft

5 pull out shim from under roller

Repeat for all ten rollers

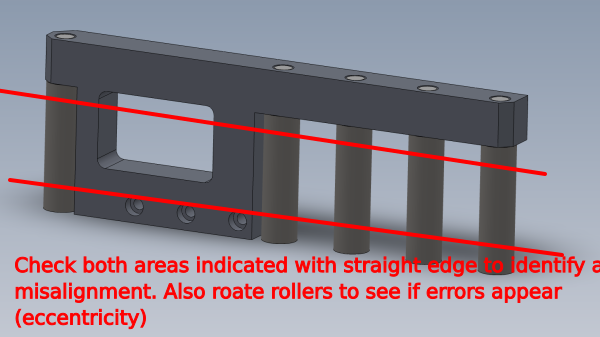

Étape 8 - Quality check

Use 1 meter straight edge to check alignment of rollers

Place straight edge against front face of rollers

Use feeler gauges to check

Mis alignment of rollers on the plain indicated

Rotate rollers individually to check for eccentric rotation.

Report any discrepancies above 0.002"/0.05mm to supervisor

All rollers should be free moving and consistent when rotated

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português