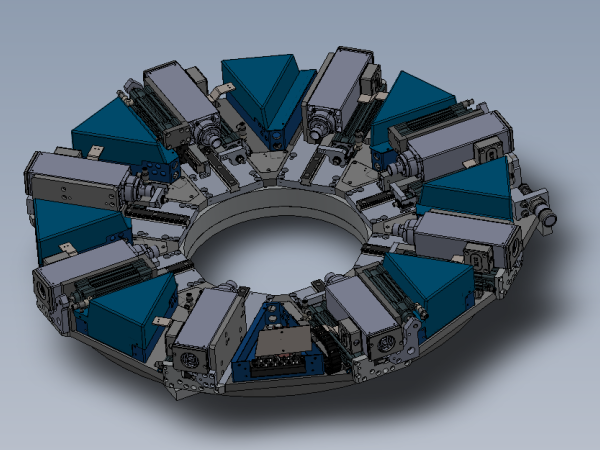

Pneumatic function test for Rotary Ring

Sommaire

- 1 Étape 1 - Lubrication

- 2 Étape 2 - Connect air feed

- 3 Étape 3 - Check for air leaks

- 4 Étape 4 - Home positions

- 5 Étape 5 - Home position correction

- 6 Étape 6 - Manual valve activation

- 7 Étape 7 - Test single slide bases

- 8 Étape 8 - Test double slide bases

- 9 Étape 9 - Disconnect air

- 10 Étape 10 - Finalize 4mm looms

- 11 Commentaires

Étape 1 - Lubrication

All lubrication points should be greased

2 pumps of grease to be added to each linear bearing

24 off bearings in total

4 off bearings per double slide base

2 off bearings per single slide base

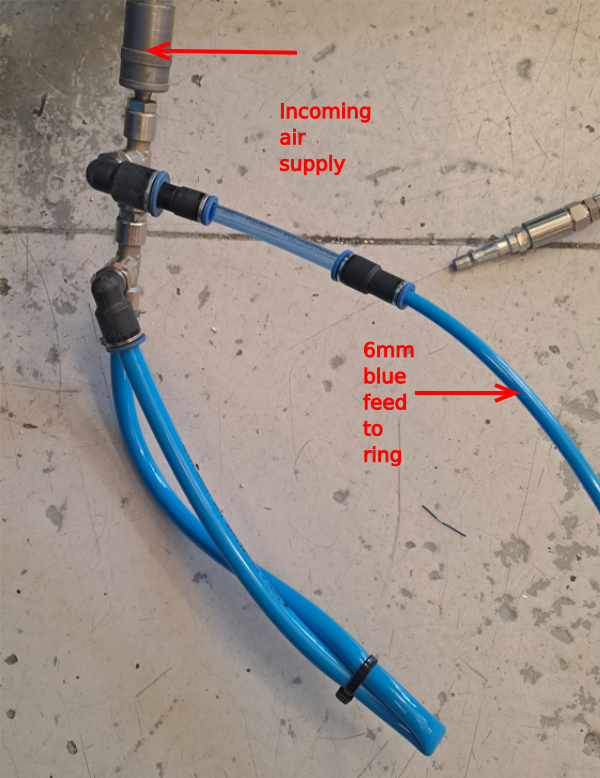

Étape 2 - Connect air feed

Compressed air feed needs connecting to main 6mm blue feed pipe to ring.

Use adapter to enable safe connection via PCL coupling and probe

Étape 3 - Check for air leaks

When air is connect to rotary ring, attention should be paid to any audible air leaks. If any are present, identify source and rectify

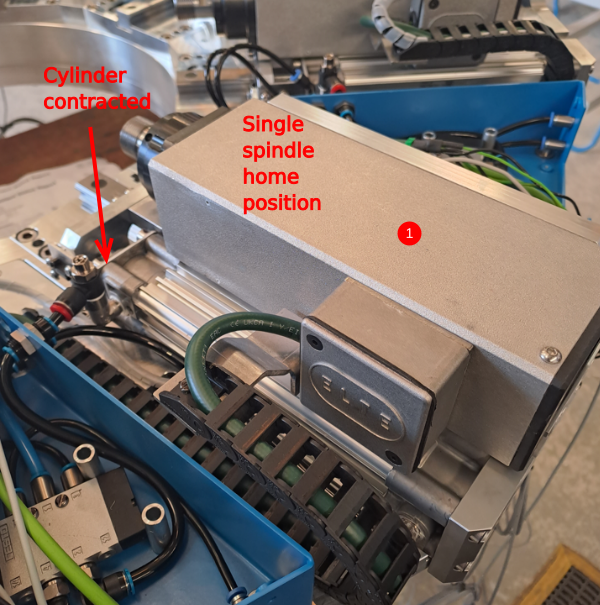

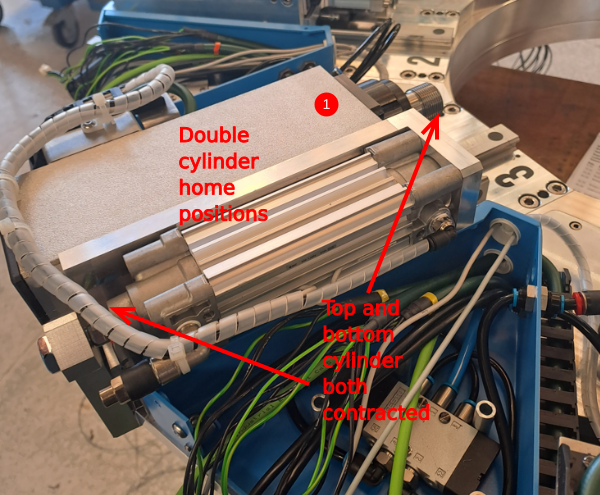

Étape 4 - Home positions

1 When air is connected, all cylinders should be in a contracted state. This is their home position

Étape 5 - Home position correction

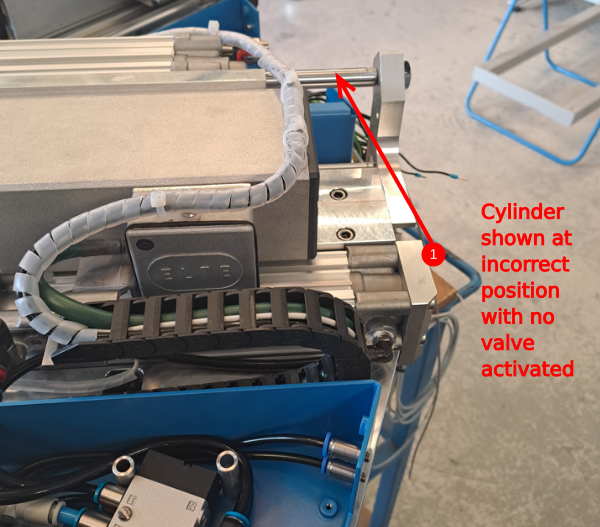

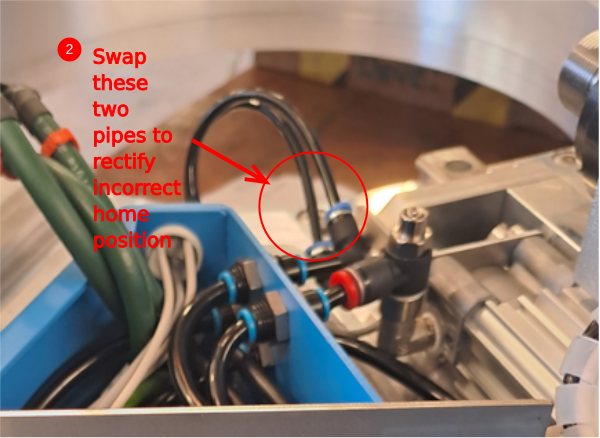

If correct practice has been followed, only the double slide cylinder will have the possibility of being at the incorrect home position . This is easily rectified

1 Image shows incorrect position when air has been connected to mains supply

2 To rectify, disconnect mains air feed and swap the two indicated pipes at the stem elbows

3 Reconnect air and confirm correct home position is now achieved

Étape 6 - Manual valve activation

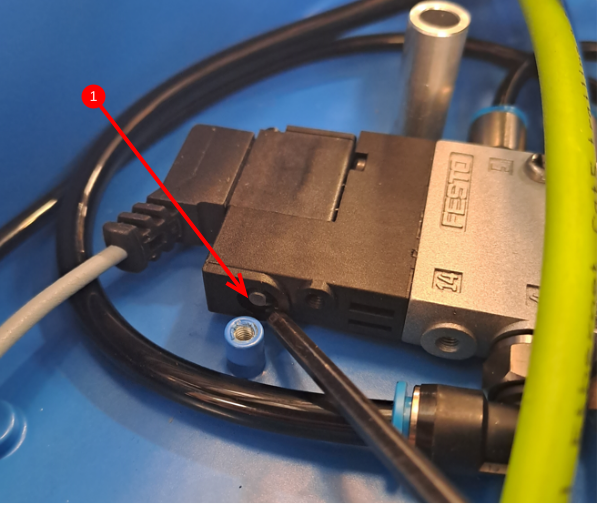

Valves can be activated manually by the control button. When pressed, the valve will fire the associated cylinder to its active position .

1 Manual valve activation button

Étape 7 - Test single slide bases

4 off

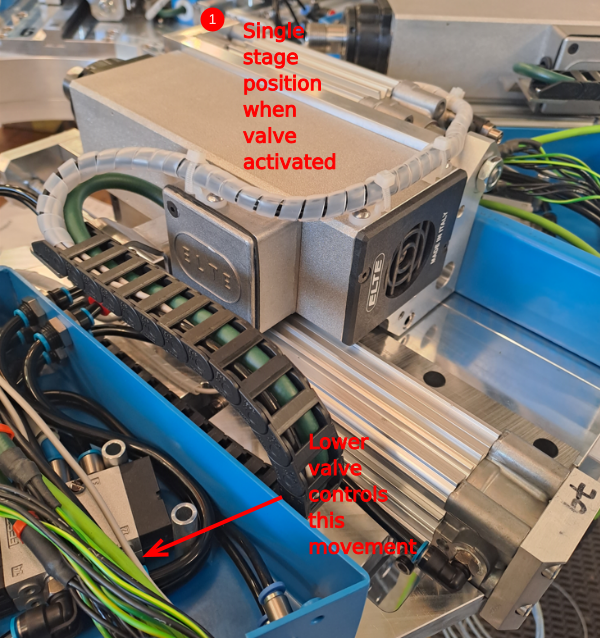

Check that when valve is activated, spindle assembly goes to the position shown. Fire valve a few times to check movement is consistent. Cylinder speeds and cushioning will be set at a later point

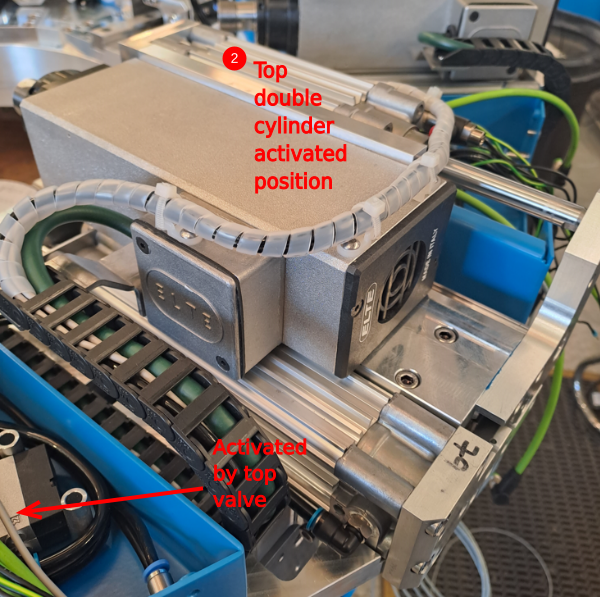

Étape 8 - Test double slide bases

4 off

Check that when valve is activated, spindle assembly goes to the position shown. Fire valve a few times to check movement is consistent. Cylinder speeds and cushioning will be set at a later point

1 Single stage cylinder activated by lower valve , see image for details

2 Double stage cylinder activated by upper valve , see image for details

Étape 9 - Disconnect air

Once pneumatic testing is complete disconnect the air supply

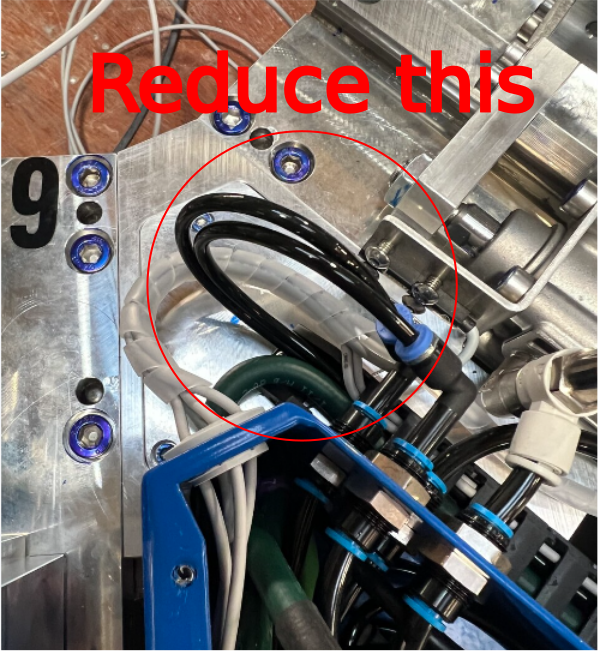

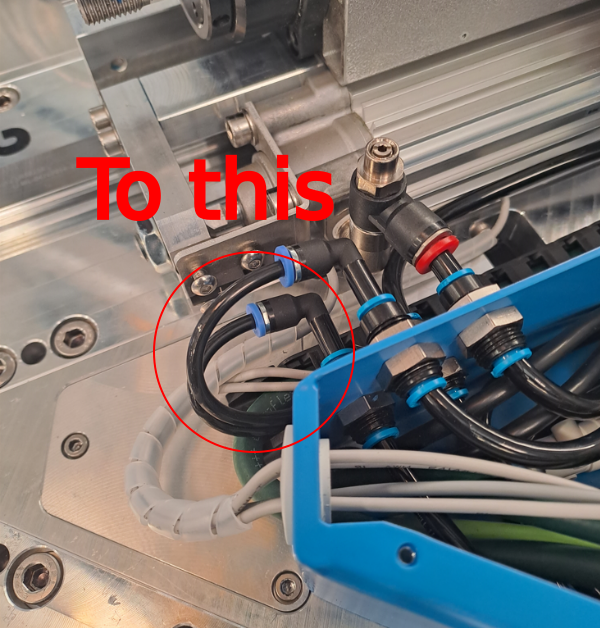

Étape 10 - Finalize 4mm looms

Once testing is complete, oversized 4mm pipe looms can be shortened to the correct length as shown. Loom length should be as minimal as possible to avoid damage

4 off spindles to finalise

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português