Fitting of control pipes and connections

Sommaire

- 1 Introduction

- 2 Étape 1 - unless otherwise stated

- 3 Étape 2 - Quality

- 4 Étape 3 - Mount Single plunge valves

- 5 Étape 4 - Mount Double plunge valves

- 6 Étape 5 - Air Feed connections

- 7 Étape 6 - Exhaust line fittings

- 8 Étape 7 - Exhaust line pipes

- 9 Étape 8 - Cylinder connections

- 10 Étape 9 - Cylinder connections

- 11 Étape 10 - Cylinder connections

- 12 Étape 11 - Quality

- 13 Étape 12 - Valve connections

- 14 Étape 13 - Valve connections

- 15 Étape 14 - Route single slide 300hz

- 16 Étape 15 - Loom sensors

- 17 Étape 16 - Connect 4mm air pipes

- 18 Commentaires

Introduction

Tools Required

Pipe cutters

Standard screwdriver set

Standard hex key set

Standard spanner set

Parts Required

D0010807 upstand collar x 32

P0001023 6mm compact y x 4

P0000456 M5-4mm straight fitting x 24

P0001091 Bulkhead 6mm straight x 24

P0001093 6mm - 4mm stem elbow x 8Étape 1 - unless otherwise stated

Use Loctite 243 on all fasteners

Pen mark all fasteners to show finalised

Étape 2 - Quality

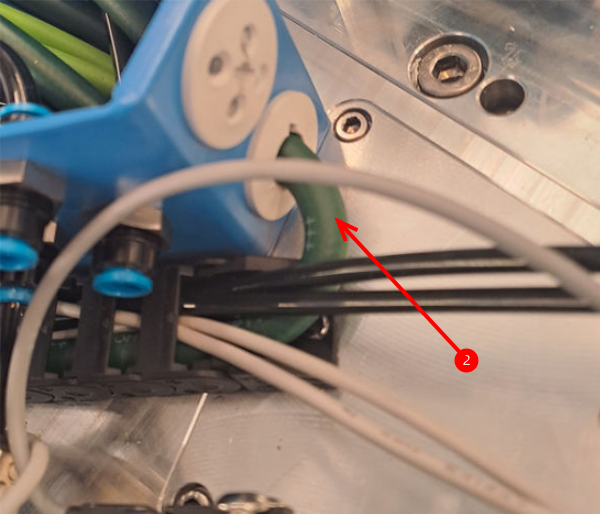

It is vital that no air pipes are kinked on installation .

Ensure all pipes are checked for correct running .

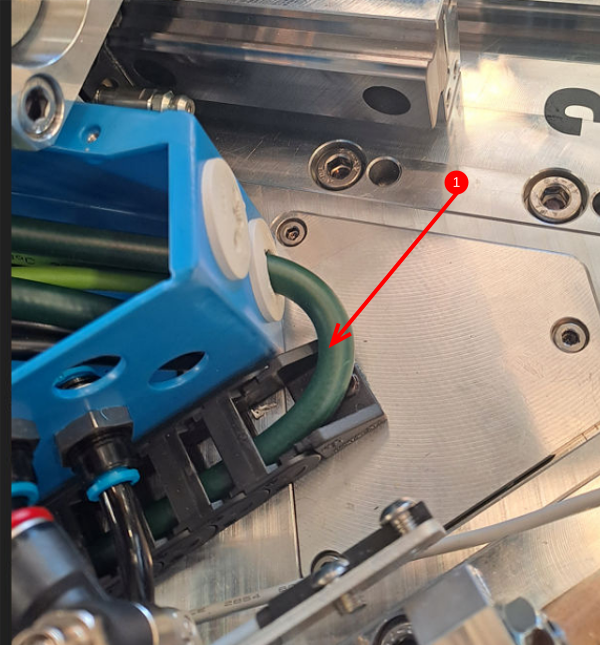

Example attached of kinked pipe

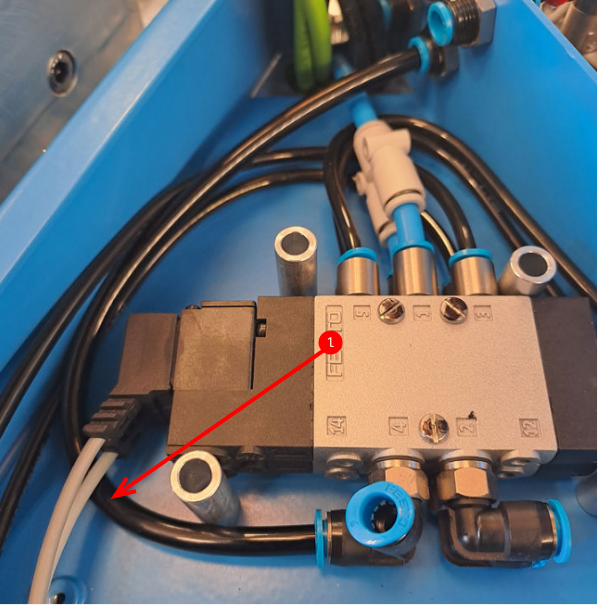

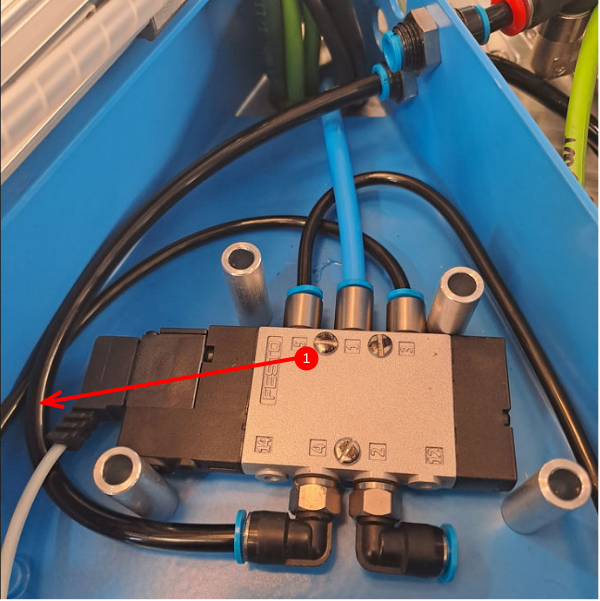

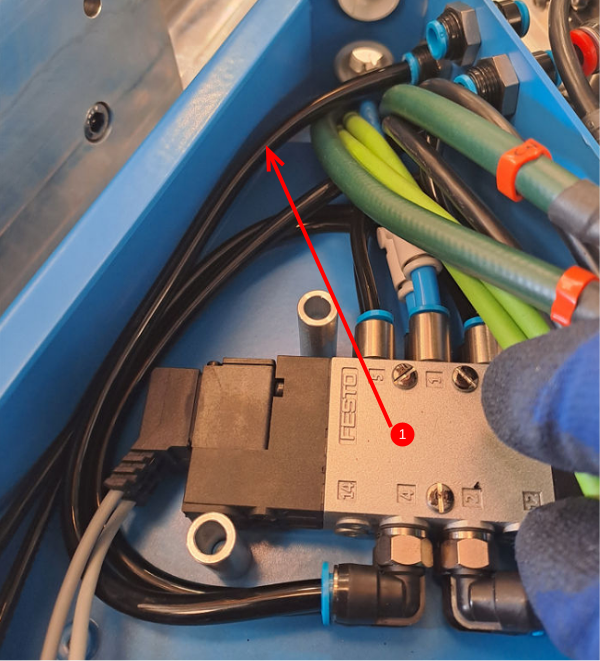

Étape 3 - Mount Single plunge valves

4 off

1 Mount pre assembled valve into spindle connection boxes to the left of the single slide spindle assembly (as viewed from rear)

2 Use 3 off M3 x 12 pan heads to secure valve to connection box as shown

3 Before tightening, add 4 off D0010807 upstand collars to define position of valve mounting

4 Finalise fixing

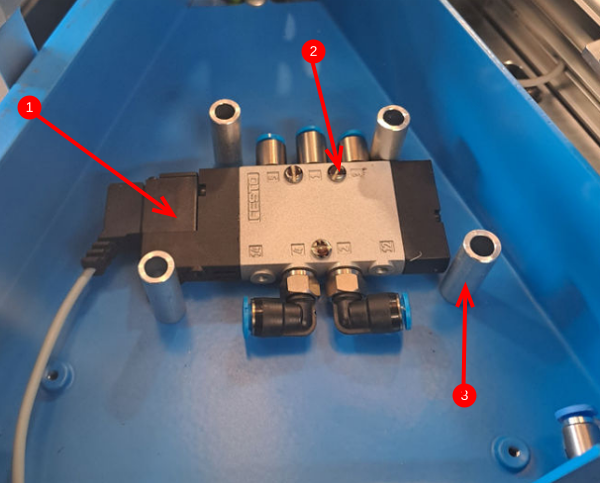

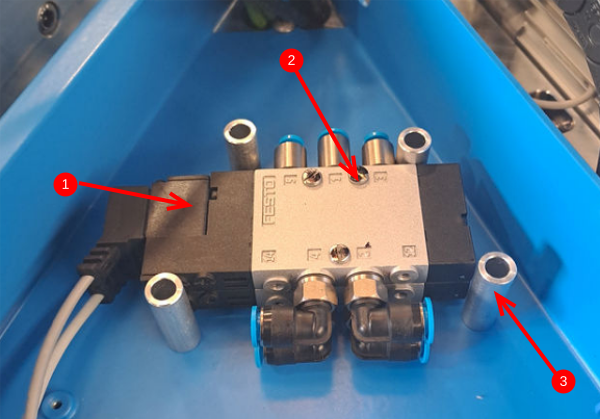

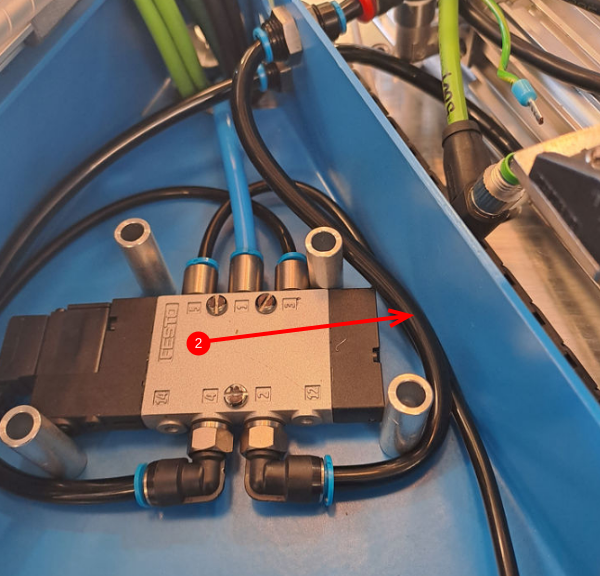

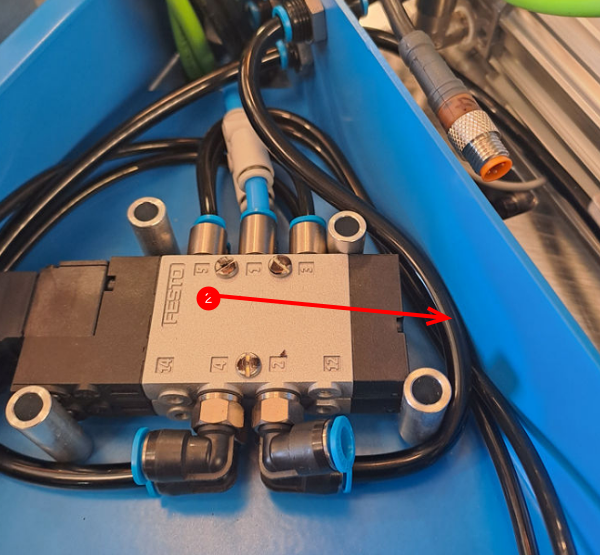

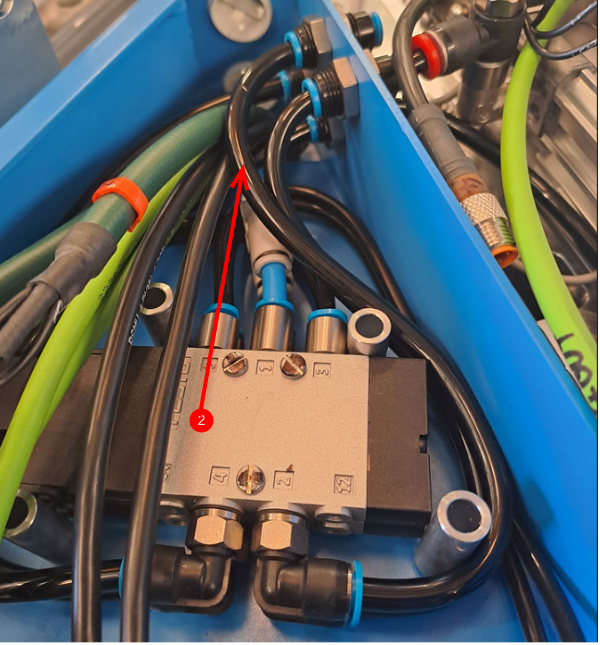

Étape 4 - Mount Double plunge valves

4 off

1 Mount double stack of valves into spindle boxes to the left of the double plunge spindle assemblies. (as viewed from rear)

2 Use 3 off M3 x 25 pan heads to secure valve to connection box as shown

3 Before tightening, add 4 off D0010807 upstand collars to define position of valve mounting

4 Finalise fixing

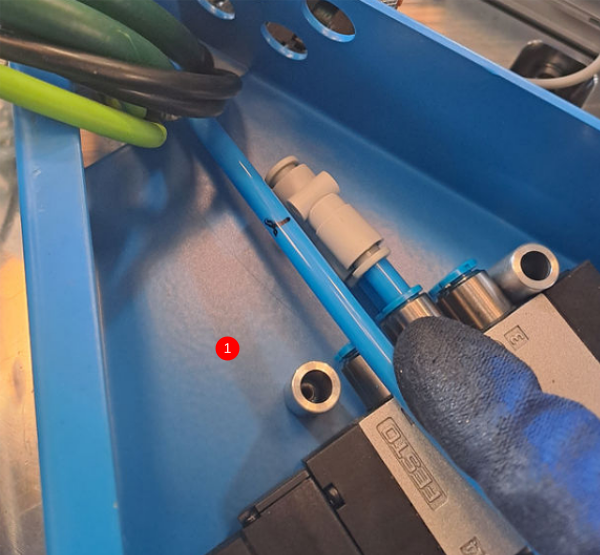

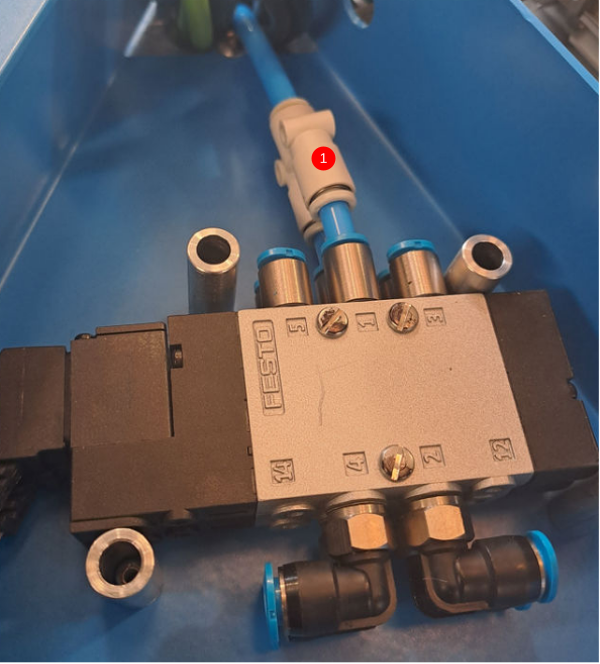

Étape 5 - Air Feed connections

1 Double valve connections

Use compact 6mm tee P0001023 and connect two valves together as picture

Lay feed pipe over top and mark length, cut and connect

2 Single valve connections

Lay feed pipe over valve fitting, mark and cut then connect

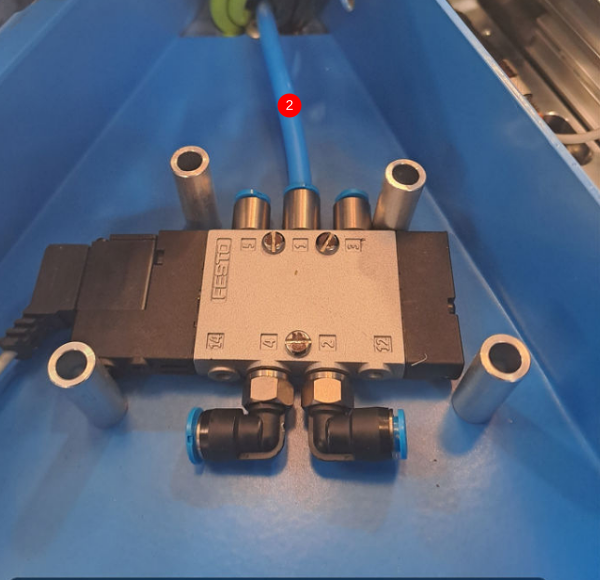

Étape 6 - Exhaust line fittings

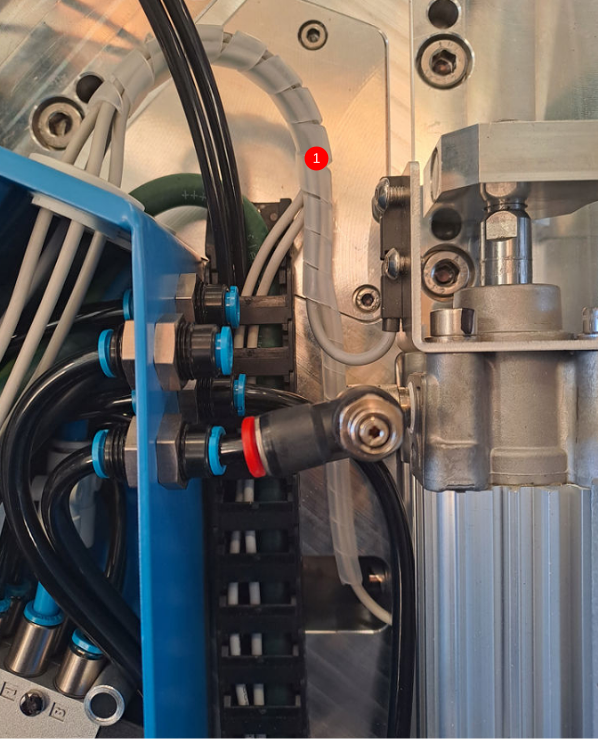

1 Fit 4 off P0000456 m5 -4mm straight fittings to double plunge connection boxes ( 2 valve boxes)

2 Fit 2 off Poooo456 m5-4mm straight fittings to single plunge connection boxes (1 valve boxes) and 2 off M5 x5 button heads as blanks

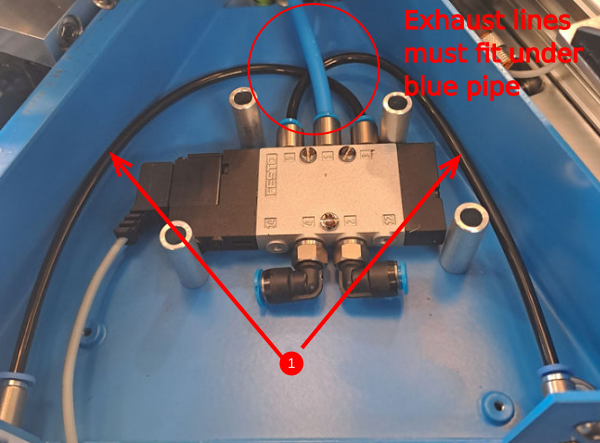

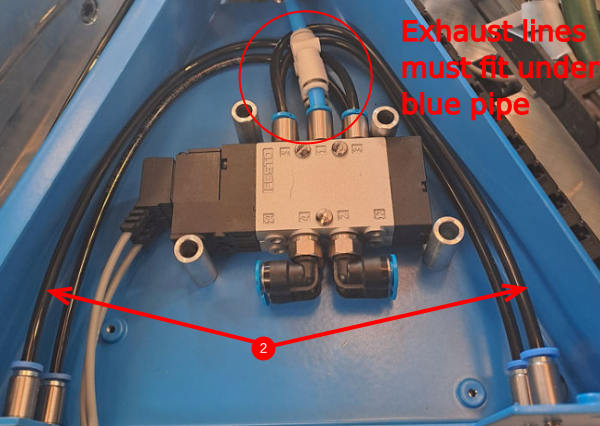

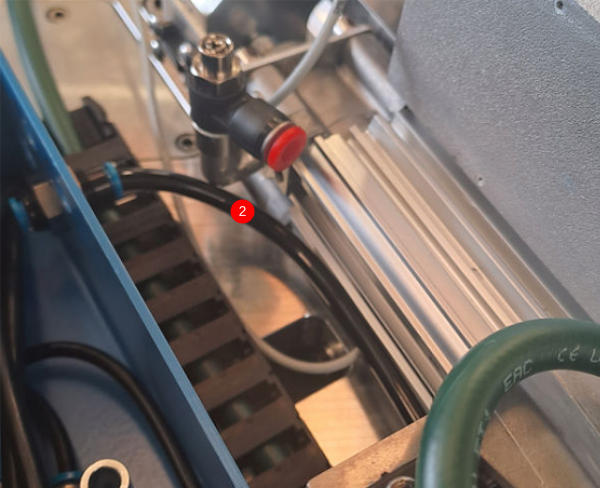

Étape 7 - Exhaust line pipes

1 Use 4mm black air pipe to connect lower valve in all connection boxes as shown

2 On double valve boxes overlay second set of pipes to connect exhausts of top valve

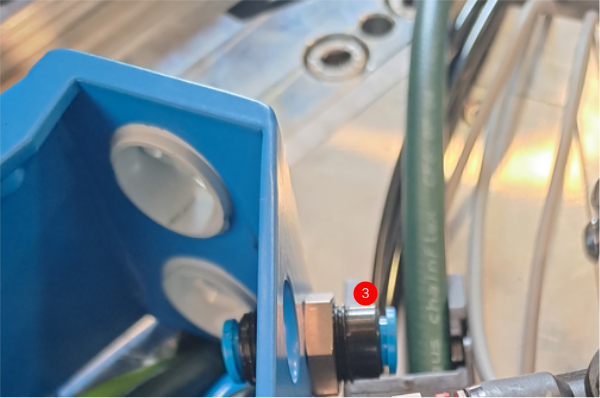

Étape 8 - Cylinder connections

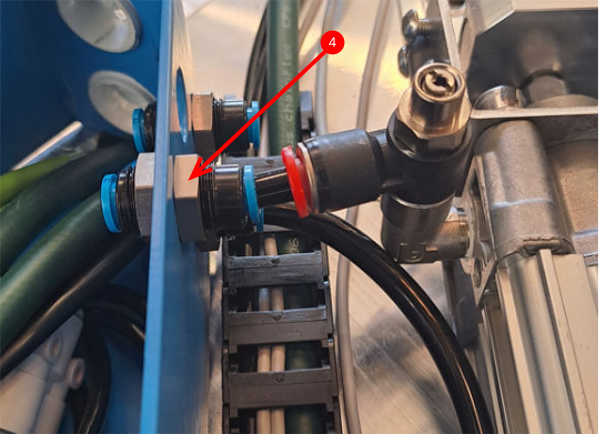

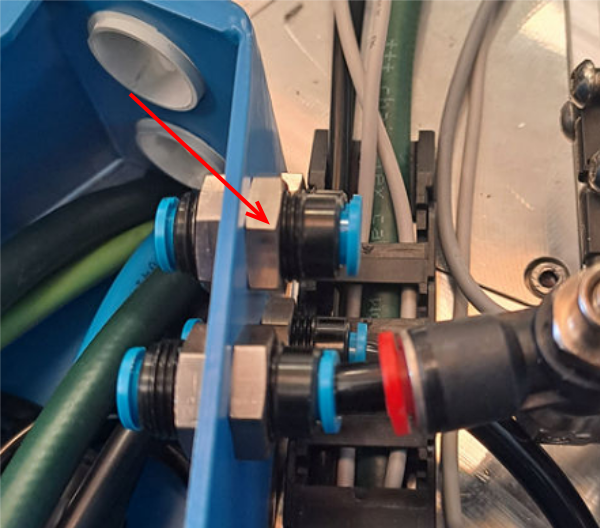

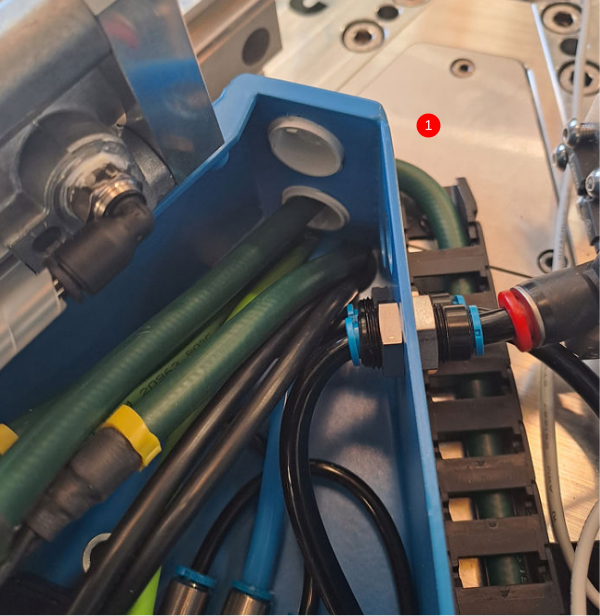

1 Fit P0001091 bulkhead connector to all spindle boxes at position shown, ensuring orientation of bulkhead is the same

2 Cut 8 pieces of black 6mm air pipe @230mm long and fit as show

3 Add P0001091 bulkhead to double slide connection boxes only as shown

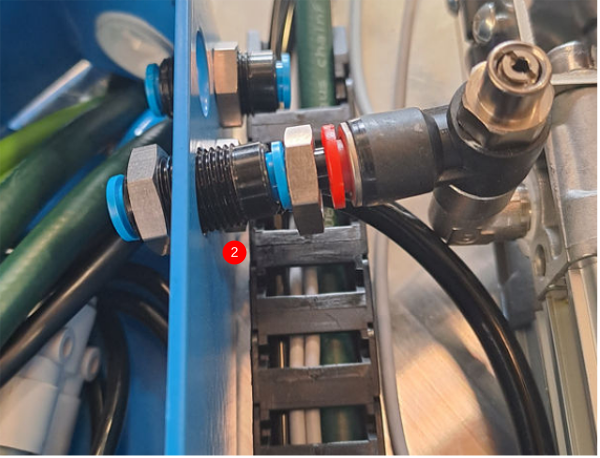

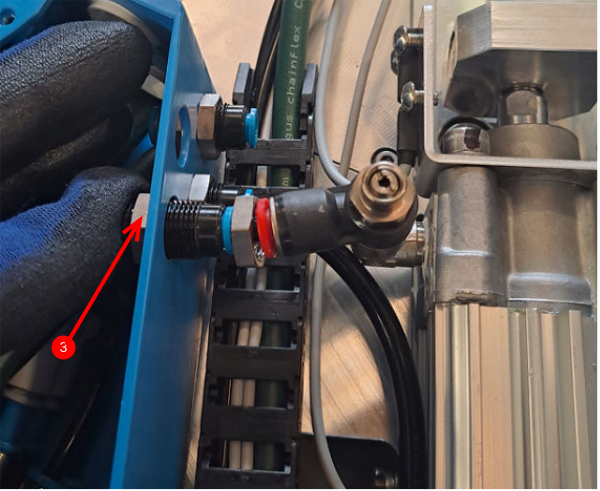

Étape 9 - Cylinder connections

1 Prepare 8 off P0001091 bulkheads with a piece of 32mm long 6mm black pipe added and one nut removed

2 Push pipe into cylinder fitting with nuts loose as shown

3 Apply force on fitting towards cylinder and run indicated nut to face to ensure no strain is added to fitting when tightening

4 Spin indicated nut to the connection box face and then tighten nuts

Étape 10 - Cylinder connections

Fit remaining p0001091 bulkhead to double slide connection boxes as shown

Étape 11 - Quality

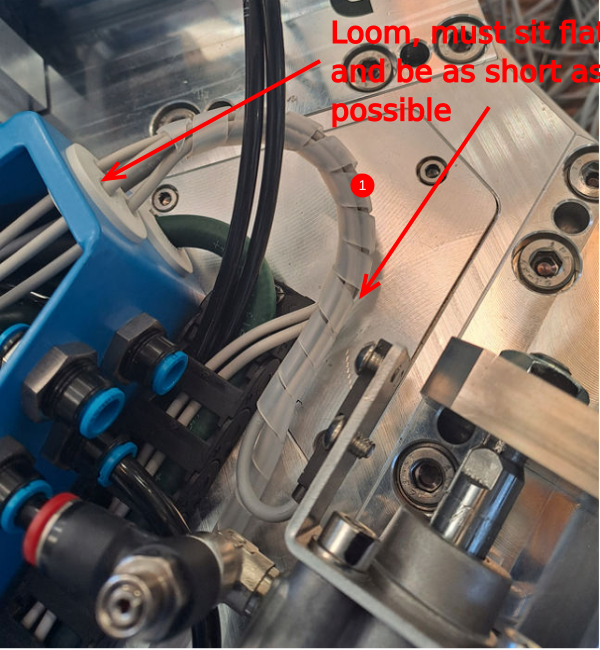

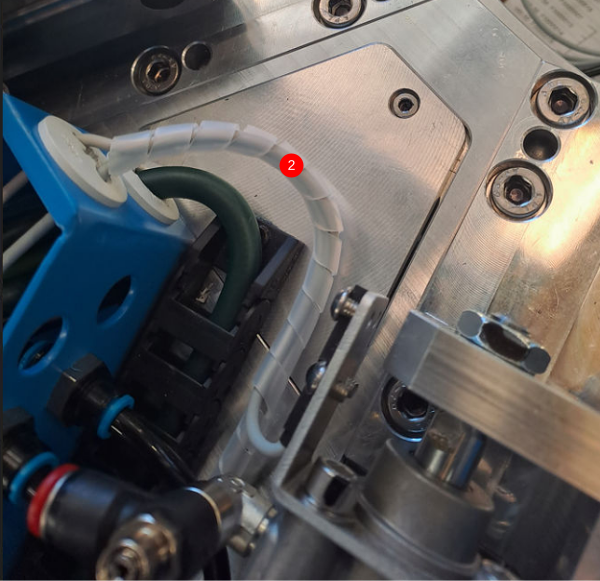

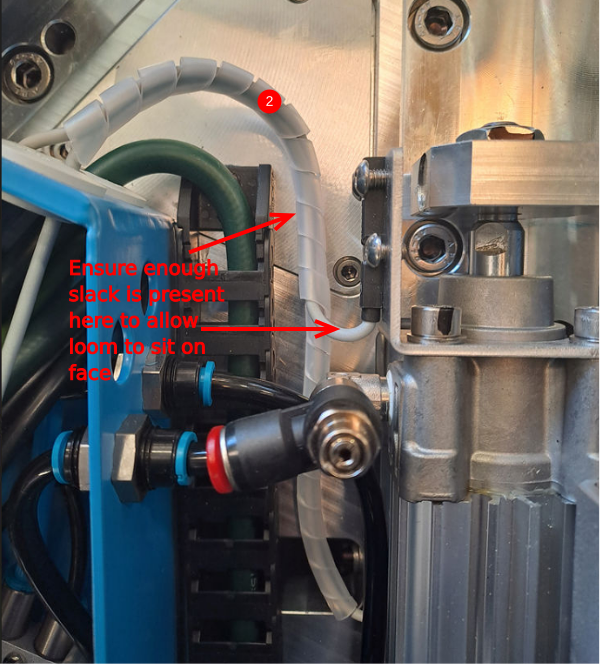

Please ensure all looms created and run are identical on each spindle head and copy examples shown . Looms must be kept to minimal size to protect from debris during operation

Étape 12 - Valve connections

1 Cut 8 off pieces of black air pipe @ 230mm and fit as shown to all connection boxes, noting pipe routing

2 Cut 8 off pieces of black 6mm air pipe @ 190mm and fit as shown to all connection boxes

Étape 13 - Valve connections

1 Cut 4 off pieces of 6mm black airpipe @ 245mm and install in double slide connection boxes as shown, noting pipe routing

2 Cut 4 off pieces of 6mm black airpipe @ 205mm and install in double slide connection boxes as shown, noting pipe routing

Étape 14 - Route single slide 300hz

1 Install 300hz cable from single slide spindle as shown (4 off)

2 Install 300hz cable from double slide spindle as shown (4 off)

Étape 15 - Loom sensors

1 Loom with spiral wrap as shown sensors from double plunge assembly

2 Loom with spiral wrap as shown sensors from single plunge assembly

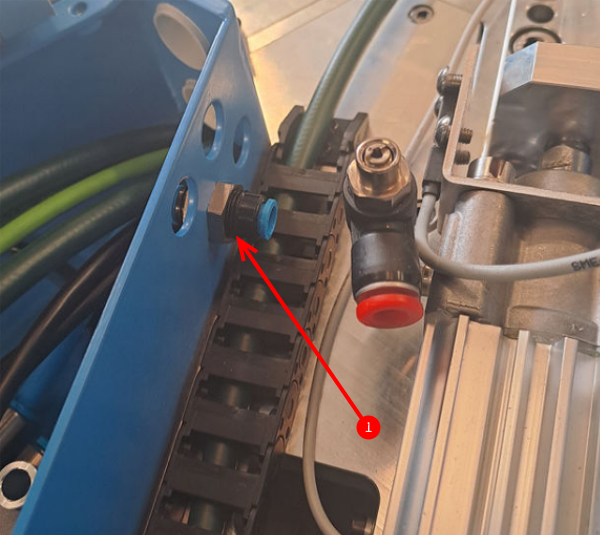

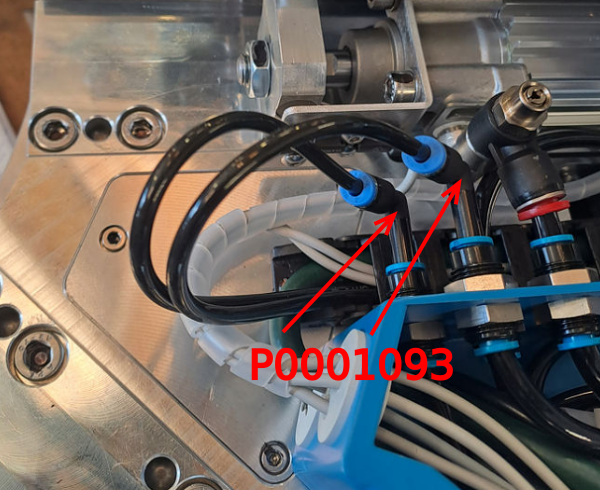

Étape 16 - Connect 4mm air pipes

Fit 2 off P0001093 stem elbows as shown then connect 4mm airpipes over length as shown to either connection ( these will be identified and tidied later on)

Repeat on remaining 3 double plunge connection boxes

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português